Nanometer silver wire conductive silver paste and preparing method thereof

A technology of nano-silver wire and conductive silver paste, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve problems such as the decrease of the adhesion of silver conductors and the shedding of silver particles, and achieve Effect of reducing silver content, improving adhesion, and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

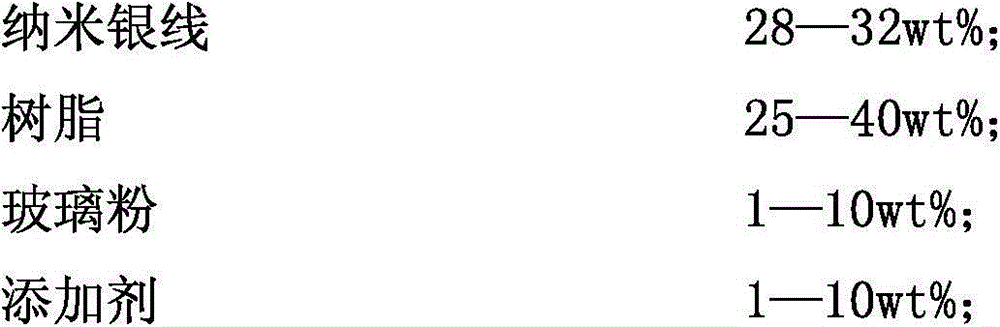

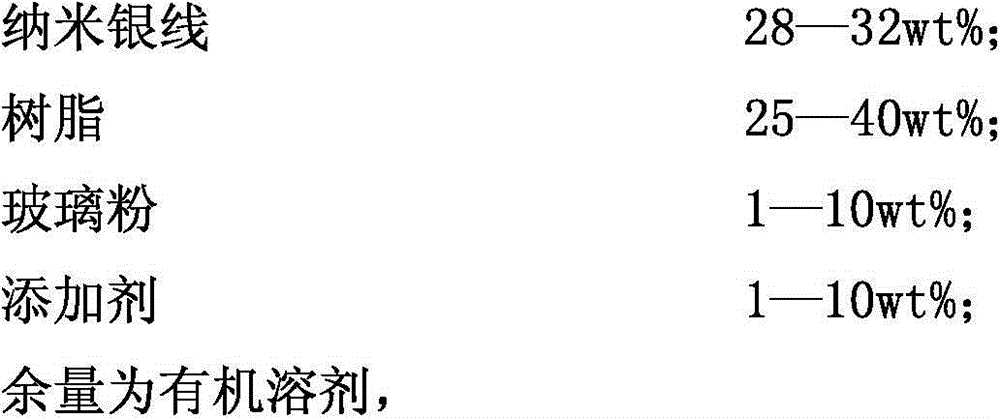

[0025] Weigh 10g of silver nitrate, 100g of glycerol, 10g of ammonium chloride, and 20g of polyvinylpyrrolidone to make a mixed solution, and stir and heat the mixed solution at 200°C for 30min. Pass the suspension of the prepared silver nanowires through a 400-mesh filter screen to separate the silver nanowires.

[0026] Weigh 30g of phenolic resin and slowly add it into 30g of butyl soluble anhydride acetate and transfer to a water bath and heat to 60°C and keep heating and stirring for 30 minutes to form an organic vehicle. Add 30g conductive silver wire, 5g glass powder and 1g carbon nanotube, 1g carbon fiber, 1g nano palygorskite, 0.5g polyglycol ether, 1.5g tetraethyl titanate to the organic carrier, and keep stirring for 30 minutes to obtain a conductive Silver paste.

[0027] After curing the conductive silver paste, its volume resistivity was tested to be 3.12Ω·m, and its viscosity coefficient was 12. At the same time, the volume resistivity of the conventional cond...

Embodiment 2

[0029] The preparation of silver nanowires is as in Example 1.

[0030] Weigh 30g of phenolic resin and slowly add it into 25g of butyl soluble anhydride acetate and transfer to a water bath and heat to 60°C and keep heating and stirring for 30 minutes to form an organic vehicle. Add 28g conductive silver wire, 4g glass powder and 1g carbon nanotube, 1g carbon fiber, 1g nano palygorskite, 0.5g polyglycol ether, 1.5g tetraethyl titanate to the organic carrier, and keep stirring for 30 minutes to obtain a conductive Silver paste.

[0031] After curing the conductive silver paste, its volume resistivity was tested to be 3.25Ω·m, and its viscosity coefficient was 10.8.

Embodiment 3

[0033] The preparation of silver nanowires is as in Example 1.

[0034] Weigh 40g of phenolic resin and slowly add it into 30g of butyl soluble anhydride acetate and transfer to a water bath and heat to 60°C and keep heating and stirring for 30 minutes to form an organic vehicle. Add 32g conductive silver wire, 8g glass powder and 2g carbon nanotube, 2g carbon fiber, 2g nano palygorskite, 1g polyglycol ether, 3g tetraethyl titanate to the organic vehicle, and keep stirring for 30 minutes to obtain conductive silver paste .

[0035] After curing the conductive silver paste, its volume resistivity was tested to be 3.15Ω·m, and its viscosity coefficient was 11.4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistivity | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com