Method for preparing super capacitor electrode material

A technology for supercapacitors and electrode materials, applied in hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, double-layer capacitors, etc., can solve the problems of low power density, specific capacitance drop, and long experiment period, and reduce the reaction temperature , good electrochemical performance, and the effect of shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

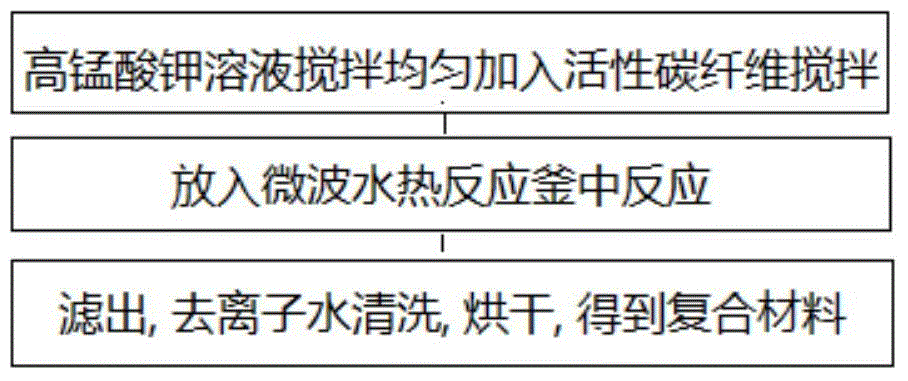

[0021] Take 0.079g of potassium permanganate and put it into 30ml of deionized water and stir until uniform, then add 0.2g of the cleaned activated carbon fiber into the potassium permanganate solution and stir for 10min, then transfer the mixed solution to the reaction kettle under microwave power 300W, 120°C microwave water heating for 30min, after washing, drying at 60°C for 12h to get the composite material.

[0022] Active materials, conductive additives (super P), and binders (PTFE) were mixed according to the mass ratio of 85:10:5, rolled into sheets, and the electrode materials were tested by the three-electrode method. The reference electrode was Ag / AgCl, and the counter electrode It is a platinum sheet, and the electrolyte is selected as the commonly used 1M Na 2 SO 4 Solution, the voltage window is selected as -0.2-0.8V to test cyclic voltammetry and constant current charge and discharge. Assembled into capacitors tested at 50mA / cm 2 (10A / g) The specific capacita...

Embodiment 2

[0025] The difference between embodiment 2 and embodiment 1 is that the potassium permanganate of 0.316g has been added, and other conditions are the same, and the manganese dioxide / activated carbon fiber composite material has been obtained equally, and it is assembled into a capacitor test at 50mA / cm 2 (10A / g) The specific capacitance under the current density is 24F / g.

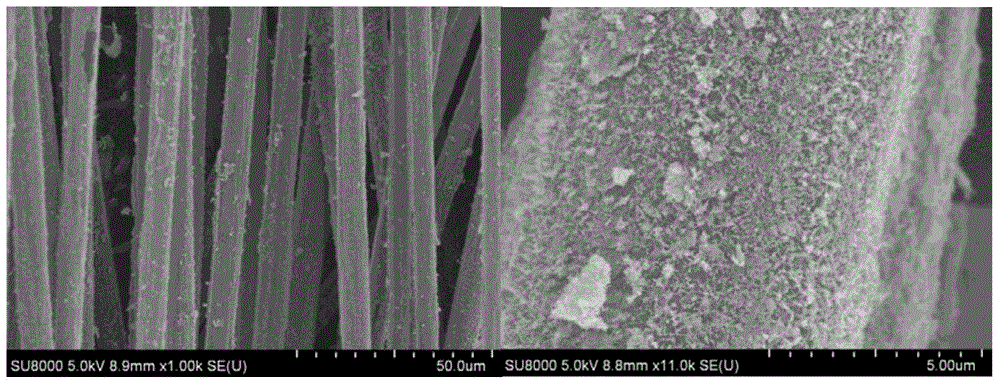

[0026] From Figure 4 In the SEM photos, it can be seen that the composite method of the two materials is that manganese dioxide is wrapped on the activated carbon fiber.

Embodiment 3

[0028] The difference between Example 3 and Example 1 is that 0.632 g of potassium permanganate was added, and other conditions were the same, and a manganese dioxide / activated carbon fiber composite material was also obtained.

[0029] From Figure 5 In the SEM photos, it can be seen that the composite method of the two materials is that manganese dioxide is wrapped on the activated carbon fiber, and the coating is very uniform. From Figure 7 It can be seen from the CV curve of the composite material that the composite material has good capacitance, and the curve is close to a rectangle. From Figure 8 The rate comparison of the three materials shows that the composite material combines the rate properties of activated carbon fiber and the high capacity of manganese dioxide. The capacity is moderate under low current, and the performance is excellent under high current. The power density has been greatly improved. , at 50mA / cm 2 (10A / g) at a high current density, the spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com