Method of preparing near-infrared carbon quantum dots by taking Coomassie brilliant blue as carbon source

A technology for Coomassie brilliant blue and carbon quantum dots is applied in the field of preparing near-infrared carbon quantum dots, which can solve the problems of waste of starch and cellulose, environmental pollution, low resource utilization rate, etc. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] a. Weigh 1.00g of turmeric powder and put it into a 50mL hydrothermal reaction kettle, add 40mL of secondary water, place it in a drying oven, adjust the reaction temperature to 200°C, and the reaction time is 2h. After the reaction, take it out and cool it to room temperature, and filter to obtain Carbon quantum dots as a stock solution;

[0023] b. Weigh 0.0429g Coomassie Brilliant Blue and dissolve it in a 50mL volumetric flask to obtain a concentration of 1.0×10 -3 The Coomassie Brilliant Blue solution of mol / L is used as stock solution;

[0024] c. Add 1mL of Coomassie Brilliant Blue and 2mL of carbon quantum dot solution into a 50mL reaction kettle, add 37mL of secondary water, place in a dry box, adjust the reaction temperature to 200°C, and react for 4 hours. After the reaction, take it out and cool to room temperature , to filter near-infrared carbon quantum dots;

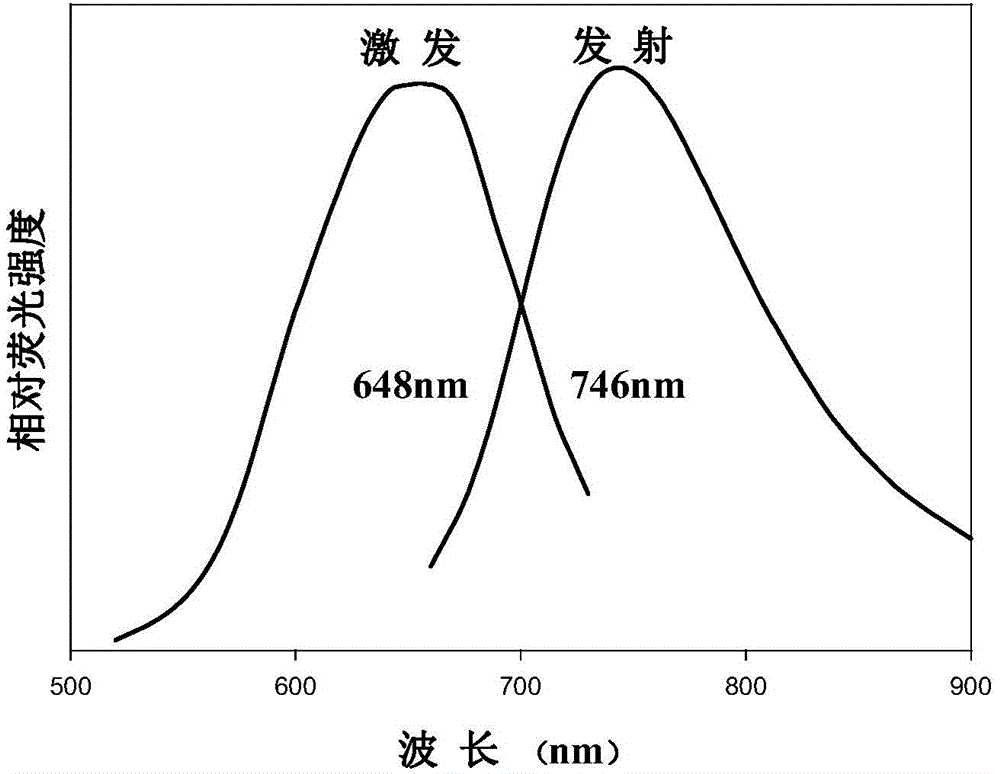

[0025] The excitation and emission spectra of fluorescent carbon quantum dots in this embodime...

Embodiment 2

[0027] a. Weigh 1.00g of turmeric powder and 50mL of hydrothermal reaction kettle, add 40mL of secondary water, put it in a drying oven, adjust the reaction temperature to 200°C, and the reaction time is 4h. After the reaction, take it out and cool it to room temperature, and filter to obtain Carbon quantum dots as a stock solution;

[0028] b. Weigh 0.01507g Coomassie Brilliant Blue and dissolve it in a 50mL volumetric flask to obtain a concentration of 1.0×10 -3 The Coomassie Brilliant Blue solution of mol / L is used as stock solution;

[0029] c. Add 1mL of Coomassie Brilliant Blue and 2mL of carbon quantum dot solution into a 50mL reaction kettle, add 37mL of secondary water, place in a dry box, adjust the reaction temperature to 200°C, and react for 6 hours. After the reaction, take it out and cool to room temperature , to filter near-infrared carbon quantum dots;

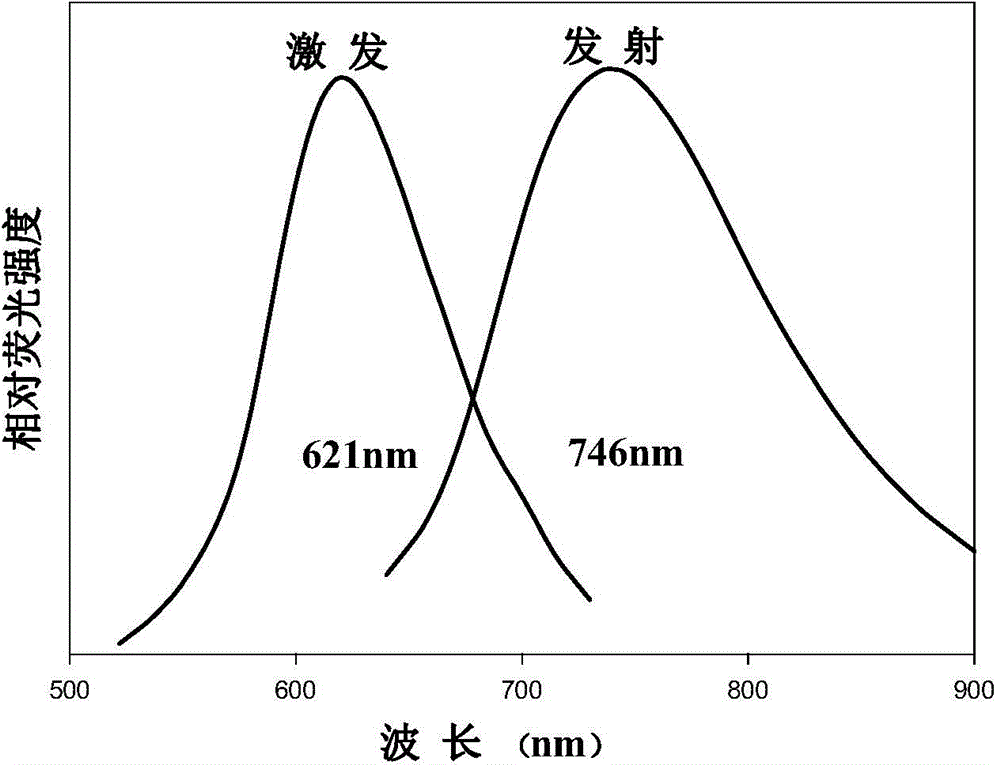

[0030] The excitation and emission spectra of fluorescent carbon quantum dots in this embodiment are as fo...

Embodiment 3

[0032] a. Weigh 1.00g of turmeric powder and put it into a 50mL hydrothermal reaction kettle, add 40mL of secondary water, place it in a drying oven, adjust the reaction temperature to 200°C, and the reaction time is 2h. After the reaction, take it out and cool it to room temperature, and filter to obtain Carbon quantum dots as a stock solution;

[0033] b. Weigh 0.01507g Coomassie Brilliant Blue and dissolve it in a 50mL volumetric flask to obtain a concentration of 1.0×10 -3 The Coomassie Brilliant Blue solution of mol / L is used as stock solution;

[0034] c. Add 1mL of Coomassie Brilliant Blue and 2mL of carbon quantum dot solution into a 50mL reaction kettle, add 37mL of secondary water, place in a dry box, adjust the reaction temperature to 200°C, and react for 8 hours. After the reaction, take it out and cool to room temperature , to filter near-infrared carbon quantum dots;

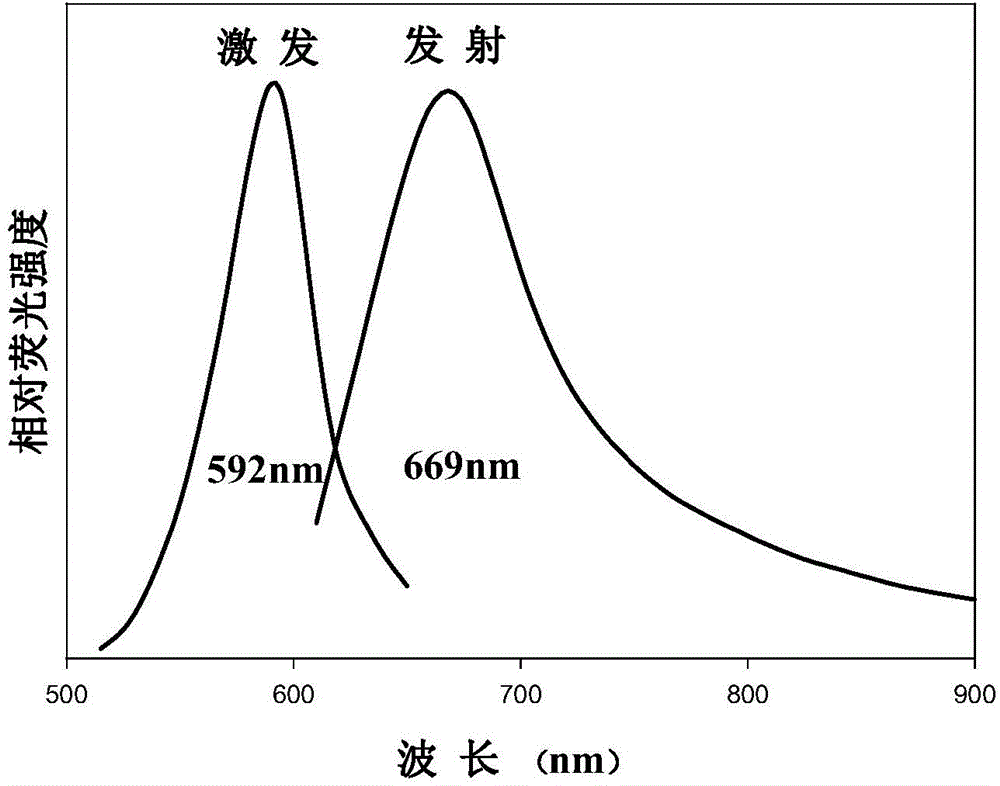

[0035] The excitation and emission spectra of fluorescent carbon quantum dots in this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com