Settleable anti-rusting water-based grinding fluid and preparation method thereof

A rust-proof water and sedimentation technology, which is applied in the field of grinding fluid, can solve the problem that fine dust such as iron powder and whetstone powder cannot be effectively sedimented, and achieve the effect of good protection, good sedimentation, and insoluble dissolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

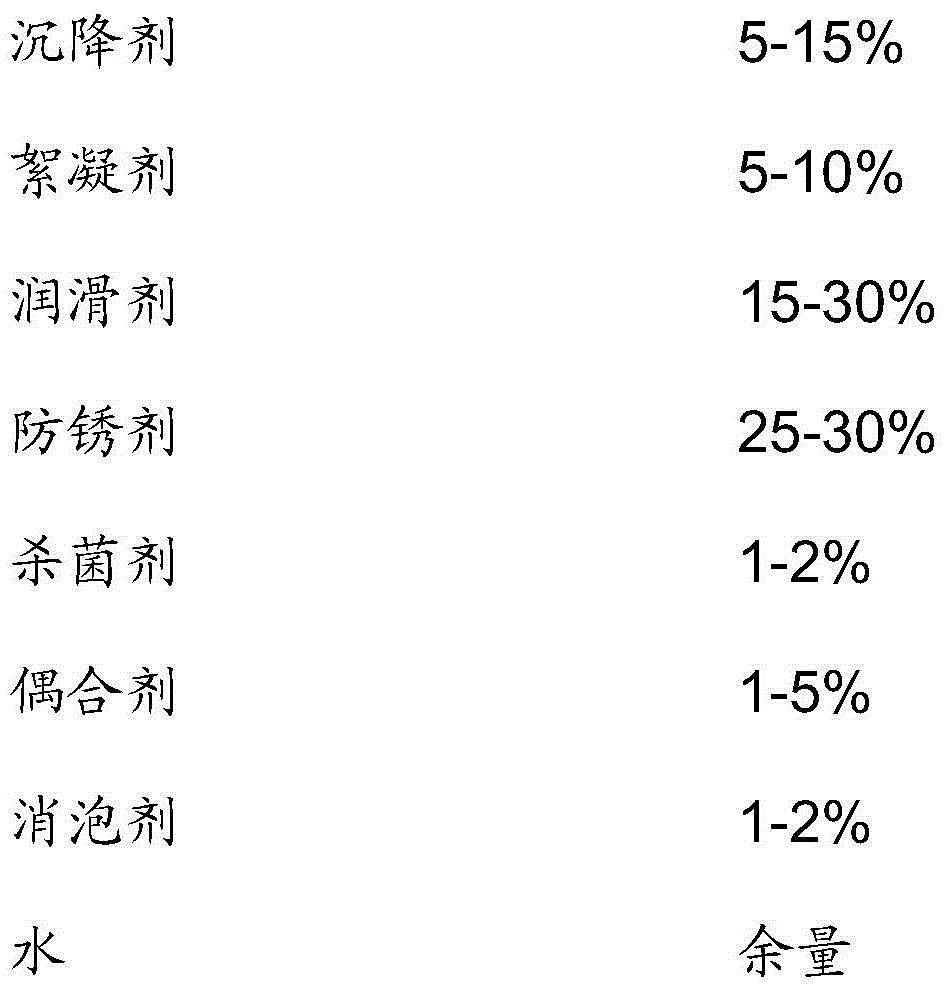

[0042] A kind of precipitating antirust water-based grinding fluid, comprising the following groups by mass percentage:

[0043]

[0044]

[0045] The settling agent is an organic sulfur sulfide.

[0046] The flocculant is selected from polyferric sulfate (PFS).

[0047] The lubricant comprises a mixture of potassium tetraborate and isomeric alcohol polyoxyethylene ethers.

[0048] The antirust agent is a mixture of tridecanedibasic acid and benzoic acid.

[0049] The fungicide is 1-hydroxyl-2(1H)-pyridinethione.

[0050] The coupling agent is diethylene glycol monobutyl ether.

[0051] The preparation method of described antirust antirust water base grinding fluid, comprises the steps:

[0052] A) Weigh or measure settling agent, flocculant, lubricant, antirust agent, bactericide, coupling agent, defoamer and water according to the formula;

[0053] B) Mix the antirust agent with water and stir for 30 minutes until it becomes a transparent and uniform liquid;

[0...

Embodiment 2

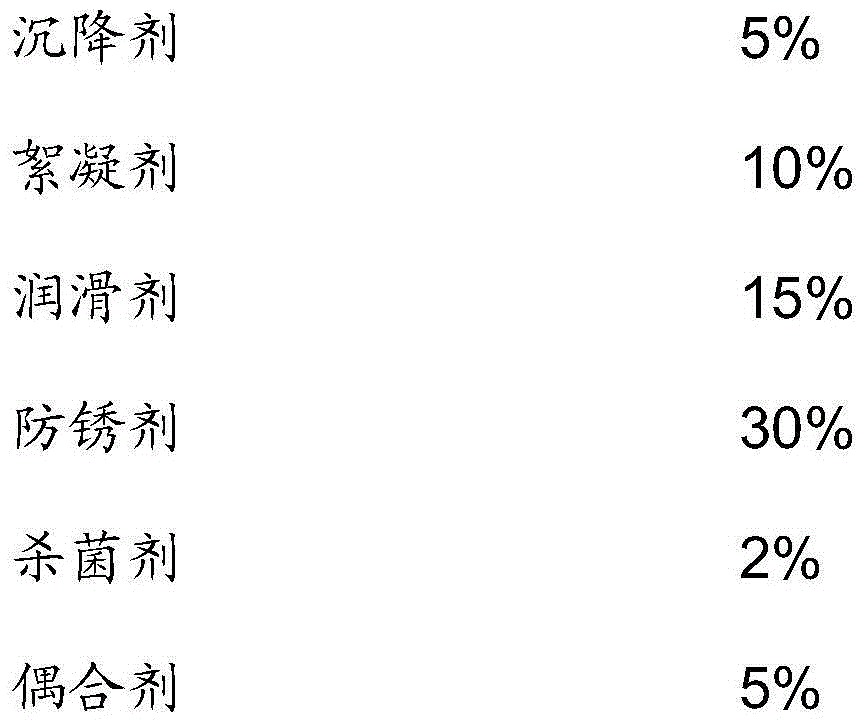

[0059] A kind of precipitating antirust water-based grinding fluid, comprising the following groups by mass percentage:

[0060]

[0061]

[0062] The settling agent is an organic mercaptan.

[0063] The flocculant is polyferric chloride.

[0064] The lubricant is potassium tetraborate.

[0065] The antirust agent is a mixture of undecanedibasic acid and methylbenzotriazole.

[0066] The bactericide is an alkylisothiazolinone.

[0067] The coupling agent is diethylene glycol monobutyl ether.

[0068] The preparation method of above-mentioned precipitative antirust water-based grinding fluid, comprises the steps:

[0069] A) Weigh or measure settling agent, flocculant, lubricant, antirust agent, bactericide, coupling agent, defoamer and water according to the formula;

[0070] B) Mix the antirust agent with water, heat to 50°C, and stir for 30 minutes until it becomes a transparent and uniform liquid;

[0071] C) Add the lubricant, bactericide, coupling agent, antif...

Embodiment 3

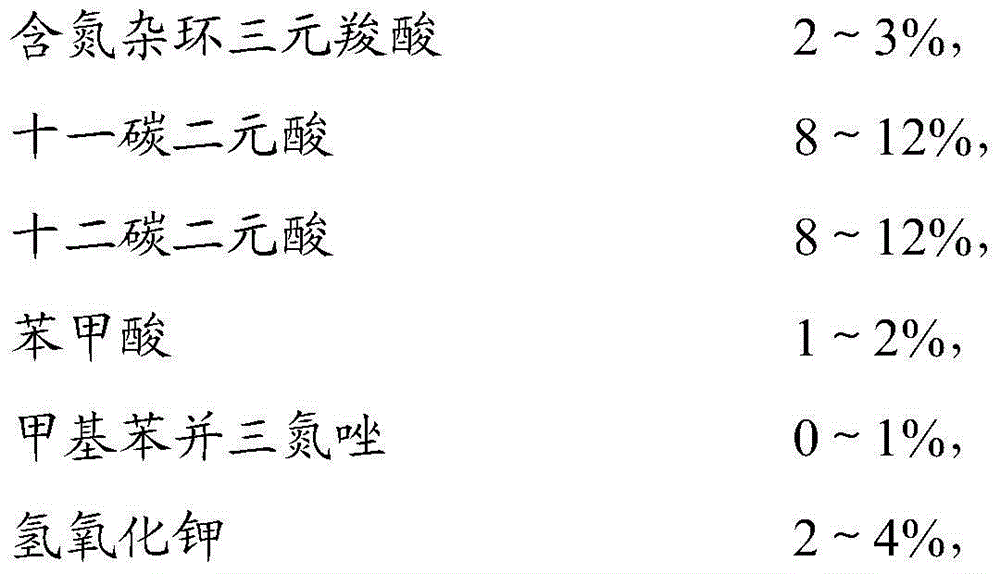

[0075] A kind of precipitating antirust water-based grinding fluid, comprising the following groups by mass percentage:

[0076]

[0077]

[0078] The settling agent is a mixture of organic thiophenols and disulfides.

[0079] The flocculant is a mixture of polyaluminum chloride and polyaluminum sulfate (PAS).

[0080] The lubricant is a mixture of isomeric alcohol polyoxyethylene ether and glycerin.

[0081] The rust inhibitor is a mixture of nitrogen-containing heterocyclic tricarboxylic acid and potassium hydroxide.

[0082] The bactericide is iodoalkyl carbamate.

[0083] The coupling agent is diethylene glycol monobutyl ether.

[0084] The preparation method of described antirust antirust water base grinding fluid, comprises the steps:

[0085] A) Weigh or measure settling agent, flocculant, lubricant, antirust agent, bactericide, coupling agent, defoamer and water according to the formula;

[0086] B) Mix the antirust agent with water and stir for 30 minutes u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com