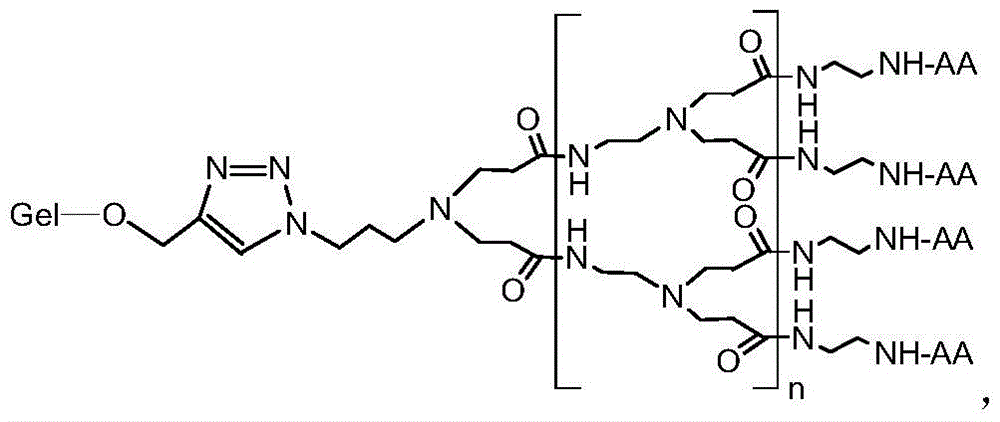

Biomimetic immunosorbent with pamam as spacer arm and its preparation method and application

A biomimetic immunization, spacer arm technology, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the heavy economic burden on patients, difficult protein sterilization process, protein immunosorbents High price and other problems, to achieve good chemical stability and mechanical strength, good hydrophilicity and blood compatibility, and improve the effect of ligand immobilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

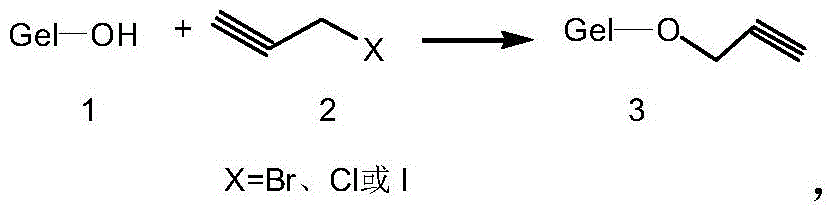

[0057] Preparation of Alkynylated Sepharose

[0058] Dissolve 0.05g of 18-crown-6 in 15ml of water in a 100mL Erlenmeyer flask, then add 4.0g of agarose, after the agarose is uniformly dispersed, add 0.3mL of propargyl bromide, and stir at 20°C for 60h. After the reaction is completed, wash and drain to obtain the alkynylated agarose gel:

[0059]

[0060] Gel is agarose in this example.

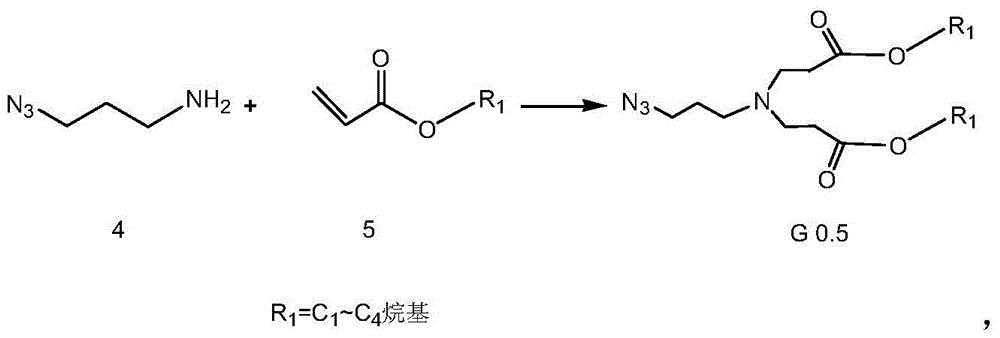

[0061] Synthesis of G3.0PAMAM Dendrimer

[0062] In a 250ml round bottom flask, first add 70ml of methanol, then add methyl acrylate (23.42g, 272mmol), place it in an ice-water bath for a period of time, so that the temperature of the system is about 0°C, and then continuously dropwise add the 30ml of methanol solution of 3-azidopropylamine (2.7g, 27.2mmol) was added dropwise and continued to react at 0°C for 1.5h, then heated to 35°C for 36h. After completion of the reaction, the product was distilled under reduced pressure to obtain G 0.5PAMAM; in a 250ml round-bottomed flask, first ...

Embodiment 2

[0078] Preparation of alkynylated cellulose gel

[0079] Dissolve 0.26g of 18-crown-6 in 20ml of water in a 100ml Erlenmeyer flask, then add 4.0g of cellulose gel balls, add 1.2ml of propargyl bromide after the cellulose is uniformly dispersed, and react at 40°C for 30h. After the reaction was completed, the alkynylated cellulose gel was obtained by washing and drying.

[0080] Synthesis of G2.0PAMAM Dendrimer

[0081] In a 250ml round bottom flask, first add 70ml of methanol, then add methyl acrylate (23.42g, 272mmol), place it in an ice-water bath for a period of time, so that the temperature of the system is about 10°C, and then continuously dropwise add the 30ml of methanol solution of 3-azidopropylamine (5.4g, 54.4mmol) was added dropwise and continued to react at 10°C for 0.5h, then heated to 20°C for 12h. After completion of the reaction, the product was distilled under reduced pressure to obtain G0.5PAMAM; in a 250ml round-bottomed flask, first add 100ml of methanol,...

Embodiment 3

[0090] Preparation of Alkynylated PVA Gel

[0091] Dissolve 0.13g of 18-crown-6 in 18mL of water in a 100mL Erlenmeyer flask, then add 4.0g of polyvinyl alcohol (PVA) gel balls, after the PVA is uniformly dispersed, add 0.6mL of propargyl bromide, and react at 60°C for 6h . After completion of the reaction, wash and dry to obtain alkynylated PVA gel.

[0092] G 4.0 Synthesis of PAMAM Dendrimer

[0093] In a 250ml round bottom flask, first add 70ml of methanol, then add 300mmol of methyl acrylate, place it in an ice-water bath for a period of time, so that the temperature of the system is about -10°C, and then continuously dropwise add 20.0mmol of 3- The methanol solution of azidopropylamine was 30ml, after the dropwise addition was completed, the reaction was continued at -10°C for 1.5h, and then the temperature was raised to 50°C for 50h. After the reaction is completed, the product is distilled under reduced pressure to obtain G0.5PAMAM; in a 250ml round bottom flask, fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com