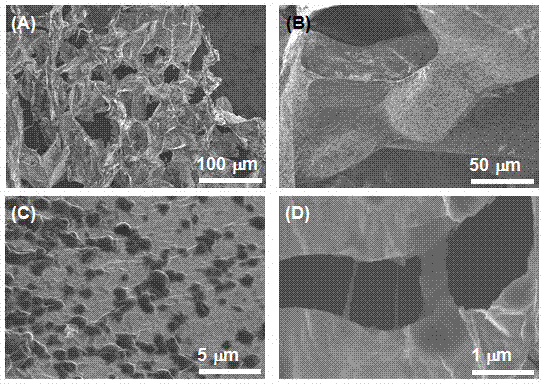

Hydrophilic graphene-carbon nano-tube composite super-light elastic aerogel and preparation method thereof

A carbon nanotube composite and carbon nanotube technology, applied in the field of hydrophilic graphene-carbon nanotube composite ultra-light elastic airgel and its preparation, to achieve low elasticity, good hydrophilicity, and simple and convenient preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the above-mentioned hydrophilic graphene-carbon nanotube composite ultra-light elastic airgel, the steps are as follows:

[0025] (1) dispersing 1 part by weight of graphene oxide in 10 to 4000 parts by weight of water to form a graphene oxide dispersion;

[0026] (2) Dispersing 1 part by weight of carbon nanotubes in 5 to 4000 parts by weight of the graphene oxide dispersion prepared in step 1 to obtain a graphene oxide-carbon nanotube dispersion;

[0027] (3) adding 1 part by weight of a polymer aqueous solution with a mass fraction of 0.01% to 80% to 0.001 to 4000 parts by weight of a graphene oxide-carbon nanotube dispersion to obtain a three-phase composite dispersion;

[0028] (4) Freeze-dry or supercritically dry the three-phase composite dispersion to obtain hydrophilic graphene oxide-carbon nanotube airgel;

[0029] (5) The hydrophilic graphene oxide-carbon nanotube aerogel is chemically reduced or high-temperature reduced to obtain a...

Embodiment 1

[0037] Step (a): disperse 1 g of graphene oxide in 4000 g of water, and stir for 2 hours to obtain a graphene oxide dispersion;

[0038] Step (b): Disperse 1 g of carboxylated multi-walled carbon nanotubes in 4000 g of the graphene oxide dispersion obtained in step a, and stir for 10 hours to obtain a graphene oxide-multi-walled carbon nanotubes dispersion;

[0039] Step (c): adding 1 g of polyacrylic acid aqueous solution with a mass fraction of 80% to 4000 g of the graphene oxide-multi-walled carbon nanotube dispersion obtained in step b to obtain a three-phase composite dispersion;

[0040] Step (d) freeze-forming the three-phase composite dispersion obtained in step c at -100°C, and freeze-drying to obtain a hydrophilic graphene oxide-carbon nanotube airgel;

[0041] Step (e): The hydrophilic graphene oxide-carbon nanotube airgel obtained in step d was reduced in the reducing agent hydrazine hydrate (0.1% by mass fraction) at 80°C for 24 h, and the hydrophilic graphite was...

Embodiment 2

[0044] Step (a): Dispersing 1 g of graphene oxide in 200 g of water, stirring and dispersing to obtain a graphene oxide dispersion;

[0045] Step (b): dispersing 1 g of double-walled carbon nanotubes in 200 g of the graphene oxide dispersion obtained in step a, stirring and dispersing to obtain a graphene oxide-multi-walled carbon nanotubes dispersion;

[0046] Step (c): adding 1 g of polyvinyl alcohol aqueous solution with a mass fraction of 5% to 200 g of the graphene oxide-multi-walled carbon nanotube dispersion obtained in step b to obtain a three-phase composite dispersion;

[0047] Step (d) freeze-forming the three-phase composite dispersion obtained in step c at -100°C, and freeze-drying to obtain a hydrophilic graphene oxide-carbon nanotube airgel;

[0048] Step (e): The hydrophilic graphene oxide-carbon nanotube airgel obtained in step d was reduced in the reducing agent hydroiodic acid (58% mass fraction) at 80°C for 10 h, and after drying, the hydrophilic Graphene-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Static water contact angle | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com