Multi-functional sugar alcohol calcium leaf fertilizer and preparation method thereof

A technology of sugar alcohol calcium and foliar fertilizer, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of low utilization rate of calcium nitrate and insufficient supplementation of crops, etc., to solve physiological obstacles and fast absorption of crops , the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

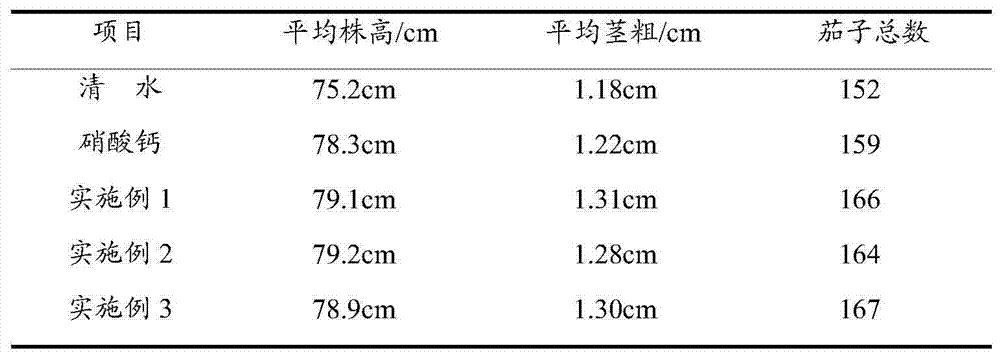

Examples

preparation example Construction

[0021] Multifunctional sugar alcohol calcium foliar fertilizer of the present invention is prepared by the following method, specifically:

[0022] Use crystalline glucose monohydrate as raw material, dilute with pure water to obtain a glucose solution with a mass concentration of 50-60%; add boric acid to the glucose solution to adjust the pH to 2.5-3.5, and add catalyst molybdate; in a high-pressure hydrogenation kettle The epimerization reaction is carried out to partially convert the glucose into mannose, the conversion rate is 30%-37%, and the solution A is obtained, and the reaction temperature is 115-125°C.

[0023] Add Ca(OH) to the above solution A 2 Adjust the pH to be neutral, add the catalyst Raney nickel, the addition amount is 1-1.5% of the weight of glucose on a dry basis, and carry out the hydrogenation reaction in the high-pressure hydrogenation kettle, and raise the temperature to 120-140°C under the pressure of 8-9MPa The hydrogenation reaction was carried ...

Embodiment 1

[0029] Dilute 5.5kg of crystalline glucose monohydrate to a concentration of 60% with pure water, add boric acid to adjust the pH to 3.5, add catalyst ammonium molybdate 10g, and perform epimerization in a high-pressure hydrogenation kettle at 115°C to partially convert glucose It is mannose, and after the reaction, the content of mannose is 34.5%. solution with Ca(OH) 2 Adjust the pH to 7.0, add 5g of Raney nickel, in the kettle, under the pressure of 8Mpa, heat up to 120°C for hydrogenation reaction for 1 hour, filter to remove the catalyst, the mixed alcohol contains 34.7% of mannitol, 65.1% of sorbitol, add Calcium nitrate 5kg, calcium hydroxide adjust pH to be 8, react under the pressure of 0.3Mpa at 100 ℃ for 1.5 hours, add 300g Tween, stir well, obtain liquid calcium sugar alcohol, as calcium sugar alcohol foliar fertilizer.

Embodiment 2

[0031] Dilute 5.5kg of crystalline glucose monohydrate to a concentration of 55% with pure water, adjust the pH to 3.0 with boric acid, add 15g of catalyst ammonium molybdate, and carry out epimerization in a high-pressure hydrogenation kettle at 120°C to partially convert glucose It is mannose, and after the reaction, the content of mannose is 35.3%. solution with Ca(OH) 2 Adjust the pH to 7.0, add 5g of Raney nickel, in the kettle, under the pressure of 8Mpa, heat up to 130°C for hydrogenation reaction for 2 hours, filter to remove the catalyst, the mixed alcohol contains 34.9% of mannitol, 64.2% of sorbitol, add Calcium nitrate 4.5kg, calcium hydroxide to adjust the pH to 8, react at 130°C under a pressure of 0.3Mpa for 1.5 hours, add 350g OP-10, stir evenly to obtain liquid calcium sugar alcohol, as calcium sugar alcohol foliar fertilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com