A kind of preparation method of wet heat treatment corn resistant starch

A wet heat treatment, corn starch technology, applied in food science and other directions, can solve the problems that cannot fully meet the needs of food processing, the physical and chemical properties of natural corn starch are limited, and achieve less damage to starch structure, stable physical and chemical properties, and low operating costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

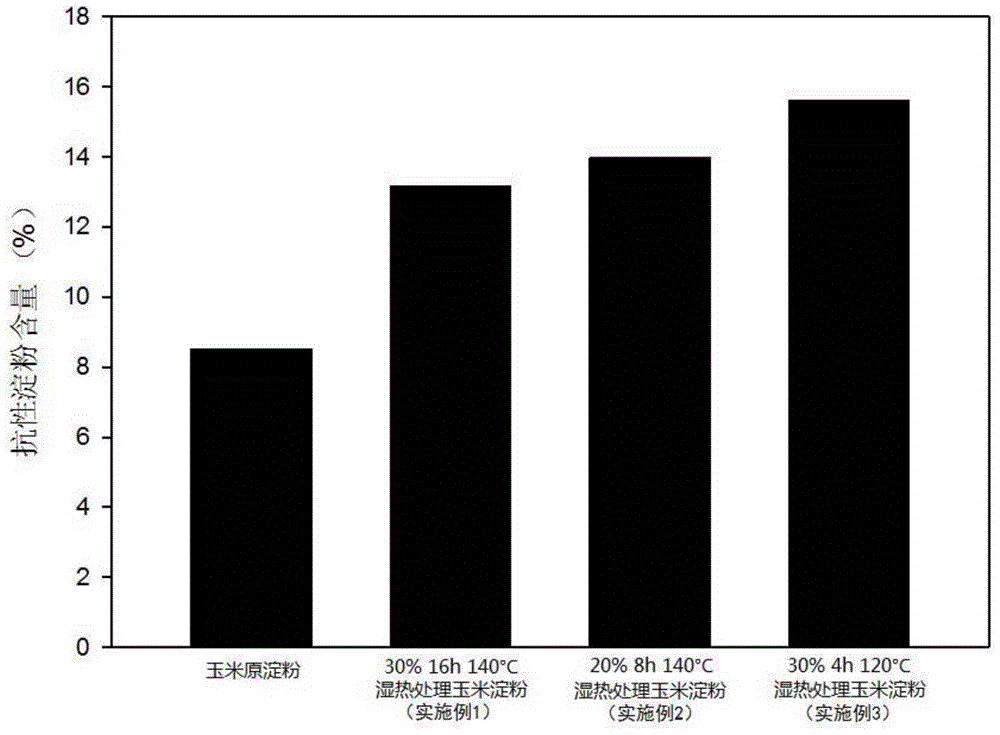

Embodiment 1

[0028] This embodiment relates to a method for preparing wet heat treatment corn resistant starch, and the method includes the following steps:

[0029] Step 1. Add 600 mL of water to 200 g of corn starch, and let it stand overnight at 4°C to allow the water to penetrate fully;

[0030] Step 2: Use a vacuum pump to suck away the excess water in the starch to reduce the water content of the starch to about 40% by mass;

[0031] Step 3: Use a dryer to adjust the moisture content of the starch to a constant 30% mass fraction;

[0032] Step 4. Equilibrate 7 days in a refrigerator at 4°C to make the water distribution uniform;

[0033] Step 5: Put the balanced starch into a screw cap bottle and place it in a constant temperature oven for treatment at a treatment temperature of 140°C and a treatment time of 16 hours. Take it out and cool it to room temperature;

[0034] Step 6, adding anhydrous ethanol to suction filtration, drying, grinding and sieving 0.4 mm aperture to prepare wet heat trea...

Embodiment 2

[0037] This embodiment relates to a method for preparing wet heat treatment corn resistant starch, and the method includes the following steps:

[0038] Step 1. Add 500 mL of water to 100 g of corn starch, and let it stand overnight at 1°C to allow the water to penetrate fully;

[0039] Step 2: Use a vacuum pump to suck away the excess water in the starch to reduce the water content of the starch to about 35% by mass;

[0040] Step 3: Use a dryer to adjust the starch moisture content to a constant 20% mass fraction;

[0041] Step 4. Equilibrate 3 days in a refrigerator at 1°C to make the water distribution uniform;

[0042] Step 5. Put the balanced starch into a screw cap bottle and place it in a constant temperature oven for treatment at a treatment temperature of 140°C and a treatment time of 8 hours, then take it out and cool it to room temperature;

[0043] Step 6, adding anhydrous ethanol to suction filtration, drying, grinding and sieving 0.4 mm aperture to prepare wet heat treatme...

Embodiment 3

[0046] This embodiment relates to a method for preparing wet heat treatment corn resistant starch, and the method includes the following steps:

[0047] Step 1. Add 300 mL of water to 300 g of corn starch, and let it stand overnight at 8°C to allow the water to penetrate fully;

[0048] Step 2: Use a vacuum pump to suck away the excess water in the caked starch, so that the water content of the starch is reduced to about 40% by mass;

[0049] Step 3: Use a dryer to adjust the moisture content of the starch to a constant 30% mass fraction;

[0050] Step 4. Equilibrate 14 days in a refrigerator at 8°C to make the water distribution uniform;

[0051] Step 5: Put the balanced starch into a screw cap bottle and place it in a constant temperature oven for treatment at a treatment temperature of 120°C and a treatment time of 4 hours, then take it out and cool it to room temperature;

[0052] Step 6, adding anhydrous ethanol to suction filtration, drying, grinding and sieving 0.4 mm aperture to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com