Non-woven fabric polymer composite diaphragm and lithium ion battery containing non-woven fabric polymer composite diaphragm

A polymer material, lithium-ion battery technology, used in secondary batteries, battery pack components, circuits, etc., can solve the problems of easy pore deformation, poor performance, high battery self-discharge rate, and achieve easy pore deformation, The effect of making holes evenly and reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

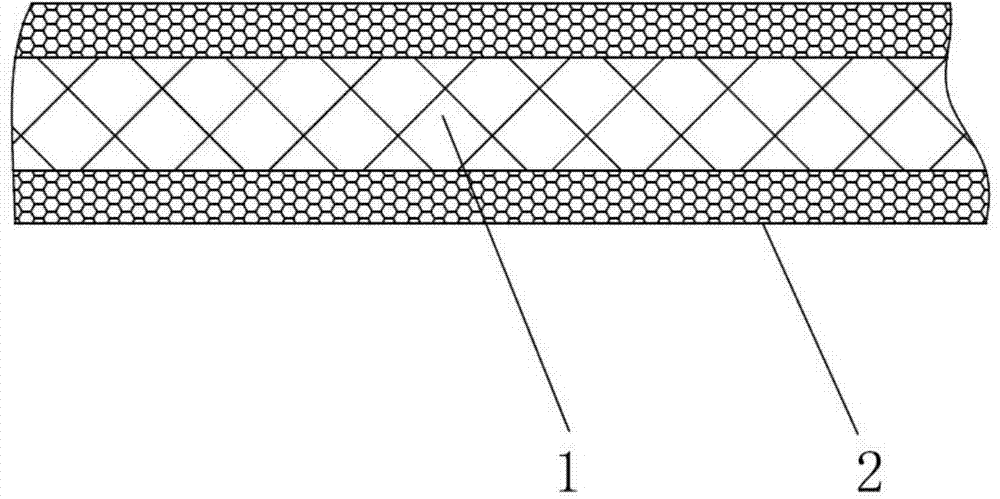

[0024] A non-woven polymer material composite diaphragm, including a base material and a polymer material layer coated on the surface of the base material, the base material is a non-woven fabric with a thickness of 10 μm, and the non-woven fabric is a non-woven fabric prepared from cellulose fibers. The woven polymer material layer is a particle coating with a particle size of 10 μm and a thickness of 1 μm. The composite diaphragm is prepared by the following steps. Select a granular polymer material with a particle size of 10 μm, and heat the polymer material particles at 100 ° C. Baking in a vacuum state for 8 hours, then dissolving the baked polymer material particles in acetone according to the mass ratio of 1:99, dispersing at high speed to form a slurry, and then coating the slurry with anilox roller or soaking method Evenly coated on the surface of the base material, after coating, the solvent component is dried in an oven to obtain a polymer non-woven material composit...

Embodiment 2

[0027] A non-woven polymer material composite diaphragm, including a base material and a polymer material layer coated on the surface of the base material, the base material is a non-woven fabric with a thickness of 40 μm, and the non-woven fabric is a non-woven fabric prepared from cellulose fibers. The woven polymer material layer is a particle coating with a particle size of 0.1 μm and a thickness of 5 μm. The composite diaphragm is prepared by the following steps. Select a granular polymer material with a particle size of 0.1, and place the polymer material particles at 100 Baking under vacuum at ℃ for 8 hours, then dissolve the baked polymer material particles in acetone according to the mass ratio of 1:99, disperse at a high speed to form a slurry, and then use an anilox roller to coat or infiltrate the slurry The method is uniformly coated on the surface of the substrate, and then dried in an oven to dry the solvent component to obtain a polymer non-woven material compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com