Reusable high temperature sealing tape for aerospace

A high-temperature sealing, aerospace technology, applied in the direction of adhesives, polymer adhesive additives, film/sheet adhesives, etc., can solve the problems of unsatisfactory economy and repeated use functions, so as to ensure the bonding strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

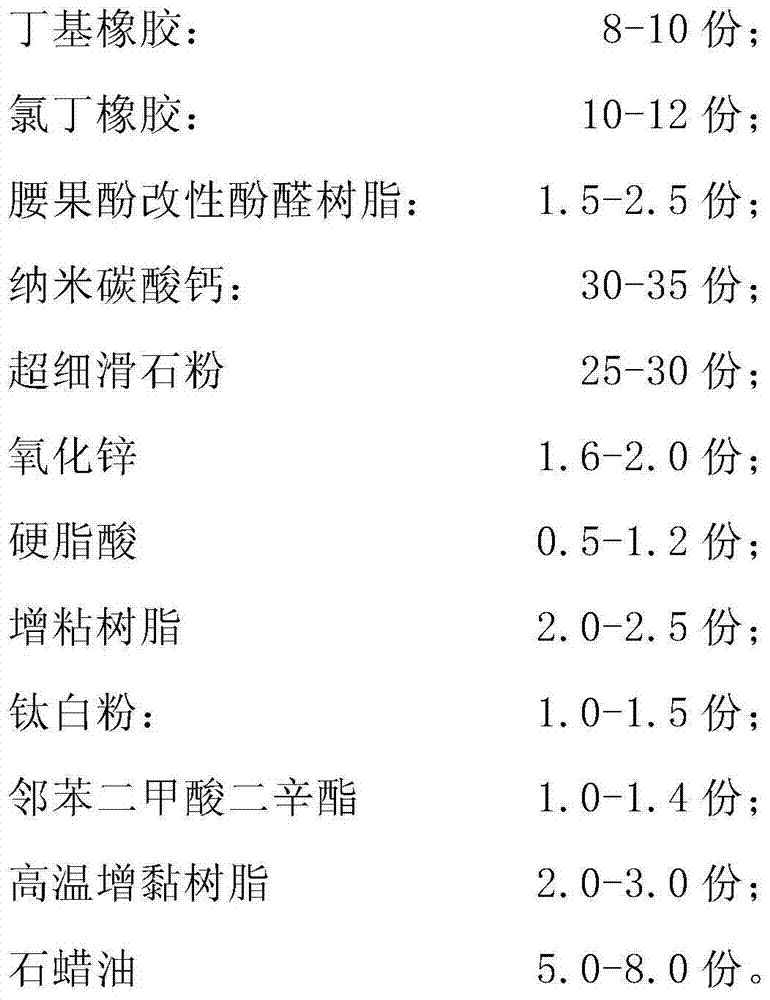

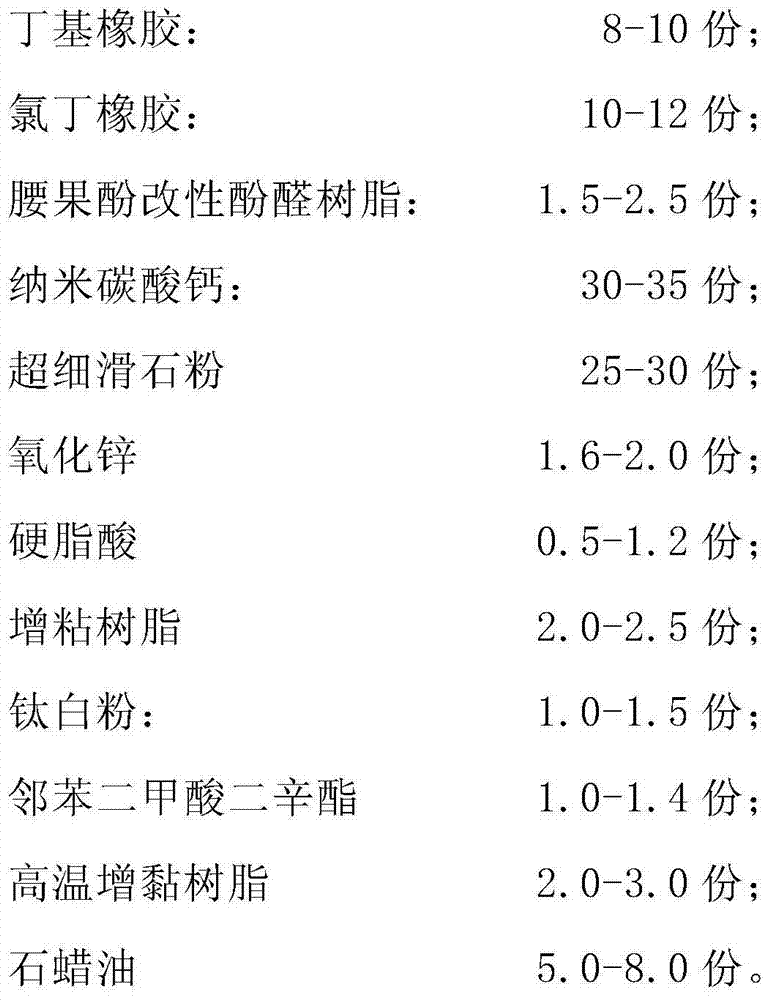

[0011] 8 parts of butyl rubber, 10 parts of neoprene rubber, 1.5 parts of cardanol modified phenolic resin, 30 parts of nano-calcium carbonate, 25 parts of superfine talcum powder, 1.6 parts of zinc oxide, 0.5 parts of stearic acid, 2.0 parts of tackifying resin , 1.0 parts of titanium dioxide, 1.0 parts of dioctyl phthalate, 2.0 parts of high-temperature tackifying resin, and 5.0 parts of paraffin oil.

[0012] The preparation method is as follows: stirring and mixing the above-mentioned components and extruding them into shape.

Embodiment 2

[0014] 9 parts of butyl rubber, 11 parts of neoprene rubber, 1.9 parts of cardanol modified phenolic resin, 32 parts of nano-calcium carbonate, 27 parts of superfine talc, 1.7 parts of zinc oxide, 0.8 part of stearic acid, 2.2 parts of tackifying resin , 1.2 parts of titanium dioxide, 1.1 parts of dioctyl phthalate, 2.3 parts of high-temperature tackifying resin, and 6.0 parts of paraffin oil.

[0015] The preparation method is as follows: stirring and mixing the above-mentioned components and extruding them into shape.

Embodiment 3

[0017] 9.5 parts of butyl rubber, 11.5 parts of neoprene rubber, 2.3 parts of cardanol modified phenolic resin, 34 parts of nano calcium carbonate, 29 parts of superfine talcum powder, 1.9 parts of zinc oxide, 1.1 parts of stearic acid, 2.4 parts of tackifying resin , 1.4 parts of titanium dioxide, 1.3 parts of dioctyl phthalate, 2.7 parts of high-temperature tackifying resin, and 7.0 parts of paraffin oil.

[0018] The preparation method is as follows: stirring and mixing the above-mentioned components and extruding them into shape.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap