Aluminum oxide adsorbent as well as preparation method and application thereof

A technology of aluminum oxides and adsorbents, applied in the fields of alumina/hydroxide preparation, chemical instruments and methods, adsorption water/sewage treatment, etc. The structure is underdeveloped and other problems, to achieve the effect of enriching the pore structure, enriching the active sites, and shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Dissolve 0.03mol of aluminum nitrate in 60mL of glacial acetic acid at room temperature to obtain mixed solution I; add 20mL of isopropanol to solution I at room temperature to obtain mixed solution II; place mixed solution II in an ultrasonic oscillator Ultrasonic reaction at 50 ° C for 1 h to obtain a transparent solution. Then place the solution in a 100mL hydrothermal reaction kettle and react for 4 hours at 200°C in a blast drying oven. After drying for 10 h, the obtained white powder is the precursor of the prepared adsorption material. Finally, the precursor was placed in a tube furnace, and the temperature was raised to 300° C. at 20° C. / min under an air atmosphere, and kept for 3 hours to obtain the adsorption material used.

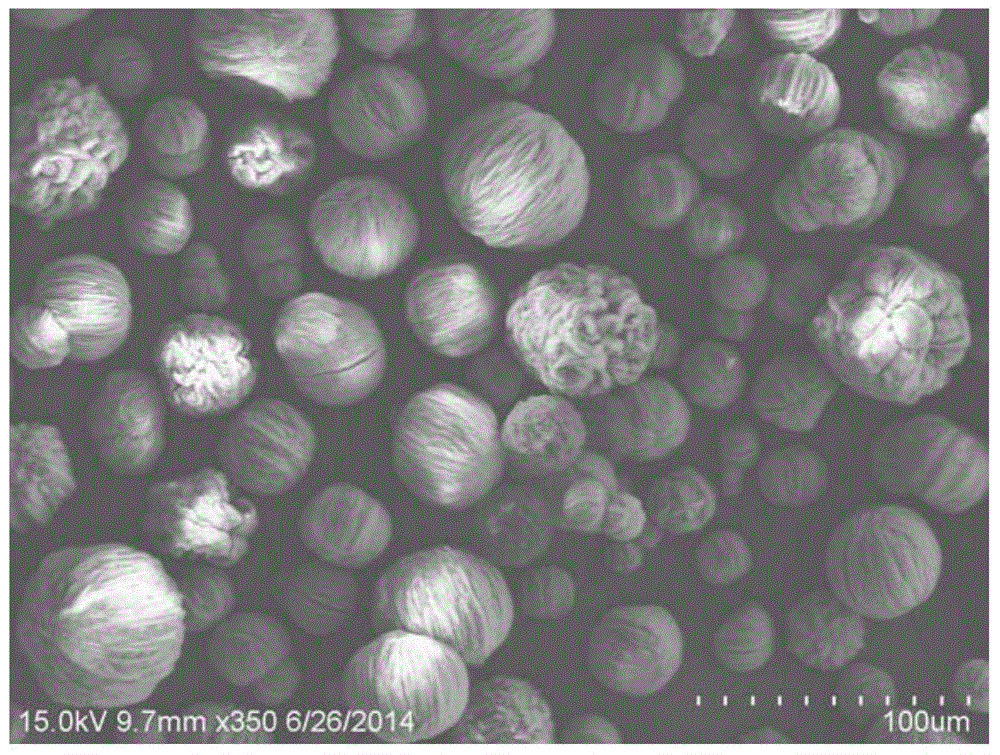

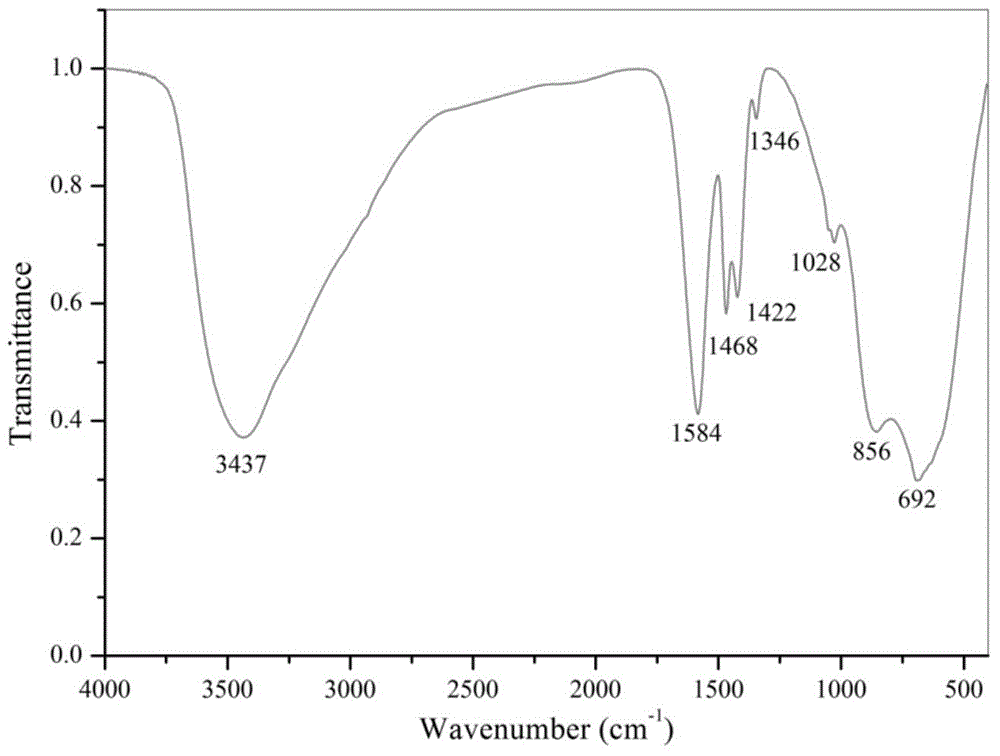

[0061] The SEM of the adsorbent material prepared by this embodiment is as follows figure 1 shown. As can be seen from the figure, the prepared material is monodisperse spherical, with a particle size between 10 μm and 50 μm. Its FTIR...

Embodiment 2

[0064] Dissolve 0.03 mol of aluminum isopropoxide in 80 mL of glacial acetic acid at room temperature to obtain a mixed solution; place the mixed solution in an ultrasonic oscillator at 50° C. for 1 h to obtain a transparent solution. Then place the solution in a 100mL hydrothermal reaction kettle and react for 2 hours at 200°C in a blast drying oven. After drying for 10 h, the obtained white powder is the precursor of the prepared adsorption material. Finally, the precursor was placed in a tube furnace, and the temperature was raised to 350° C. at 20° C. / min under an air atmosphere, and kept for 3 hours to obtain the adsorption material used.

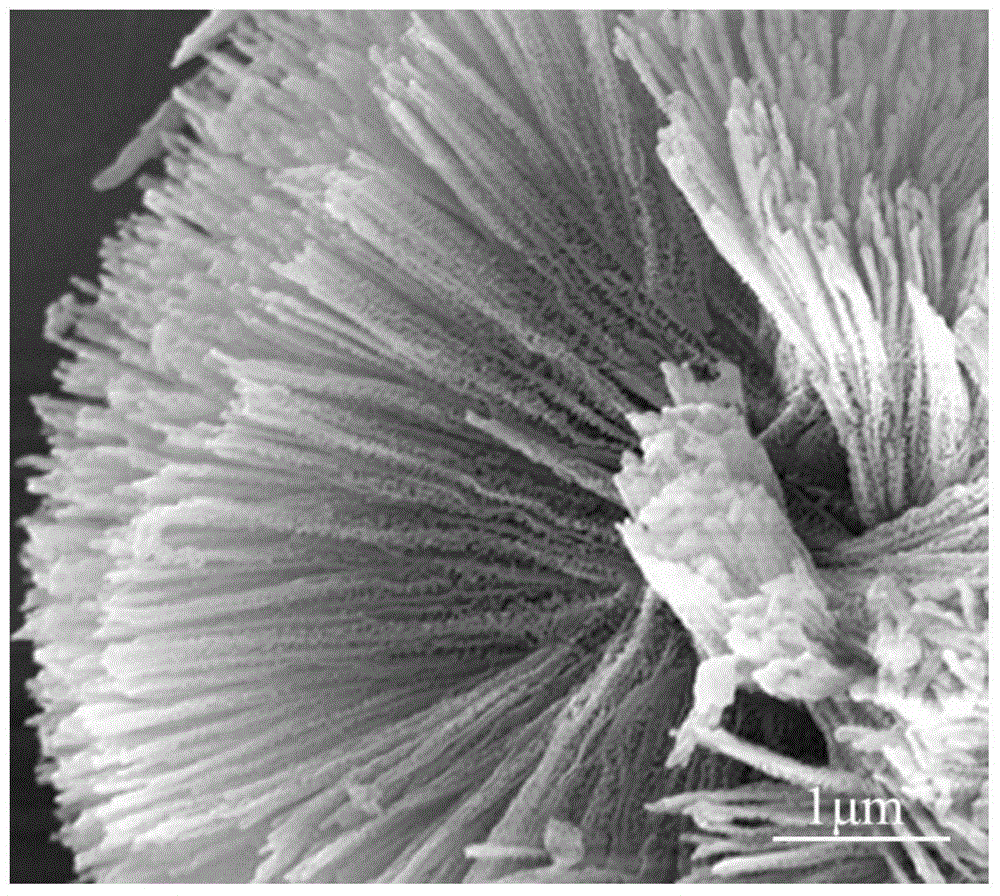

[0065] The SEM and XRD figures of the adsorbent material prepared by this embodiment are as follows image 3 , 4 shown. It can be seen from the figure that the material is in the shape of amorphous microspheres and has a well-developed pore structure, which is conducive to the adsorption and diffusion of pollutants on the surface an...

Embodiment 3

[0068] The amorphous aluminum oxide that embodiment 1,2 prepares is applied to the F that concentration is 5,10,30,50,75,100,150mg / L in removing water - , Substituting the adsorption amount values obtained at different concentrations into the following Langmuir isotherm adsorption equation and fitting:

[0069] q e = Q max b C e 1 + b C e

[0070] Among them, C e (mg / L) is F in the solution - The equilibrium concentration of q e (mg / g) is the adsorption amount at equilibrium, Q max (mg / g) is the maximum adsorption capacity per gram of adsorbent, b (L / mg) is the Langmuir constant; the fitting results are as follows Figure 6 and Figure 7 shown. It can be seen from the figure t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com