Method for preparing high-homodisperse zinc sulfide graphene composite material

A technology of uniform dispersion and composite material, applied in the field of preparation of nanocomposite materials, can solve the problems of complex process, many influencing factors, not suitable for scaled production, etc., and achieve the effect of simple synthesis method and strong repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

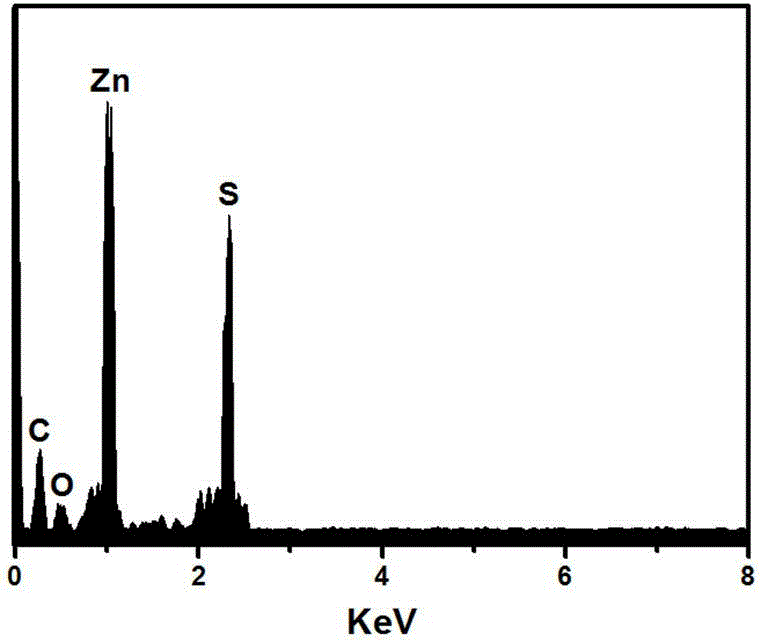

[0018] Take 0.016 g of graphene oxide, add it to 80 mL of dimethyl sulfoxide, and mix it ultrasonically for 2 h, then add 0.16 g of zinc acetate and 12 mg of sodium dodecylbenzenesulfonate, and transfer it into a 100 mL polytetrafluoroethylene-lined In the reaction kettle, solvothermal reaction was carried out at 180 °C for 12 h, the reaction product was washed with acetone and alcohol, and dried to obtain the final product. Such as figure 1 As shown, the synthesized composite material contains C, Zn, S elements.

Embodiment 2

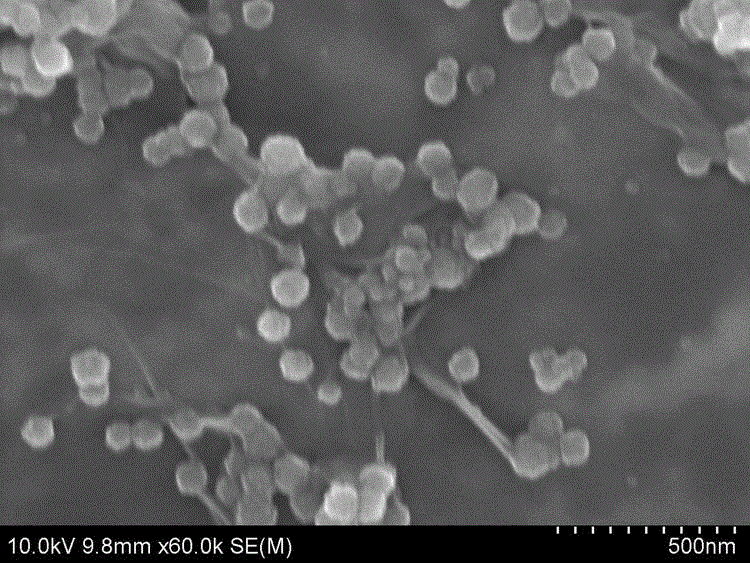

[0020] Take 0.04 g of graphene oxide, add it to 80 mL of dimethyl sulfoxide, mix ultrasonically for 2 h, then add 0.1 g of zinc oxalate and 10 mg of sodium hexadecylbenzene sulfonate, stir and mix well, transfer the solution into 100 mL In a polytetrafluoroethylene-lined reactor, solvothermal reaction was carried out at 180 °C for 20 h, the reaction product was washed with acetone and alcohol, and dried to obtain the final product. figure 2 It is the SEM picture of the composite material. It can be seen from the picture that zinc sulfide is uniformly distributed on the surface of graphene, and the particle size is about 100 nm.

Embodiment 3

[0022] Take 0.2 g of graphene oxide, add 200 mL of dimethyl sulfoxide, and mix ultrasonically for 2 h, then add 0.5 g of zinc acetate and 85 mg of dodecyltrimethylammonium bromide, stir and mix well, and then transfer to a 250 mL In a polytetrafluoroethylene-lined reactor, solvothermal reaction was carried out at 200 °C for 12 h, the reaction product was washed with acetone and alcohol, and dried to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com