Preparation methods of graphite-phase boron nitride nano wafer and colloid thereof

A graphitic boron nitride, nanotechnology, applied in chemical instruments and methods, nitrogen compounds, nanotechnology, etc., can solve problems such as difficulty in large-scale preparation and production cost, and achieve the advantages of large-scale industrial production, simple preparation process, The effect of low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The preparation steps of the present invention are as follows:

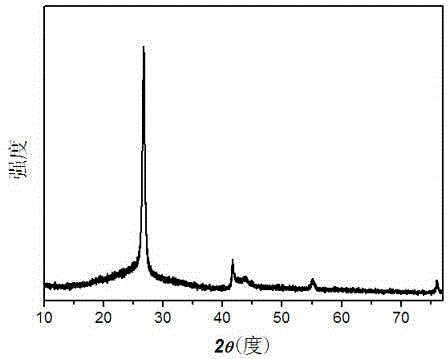

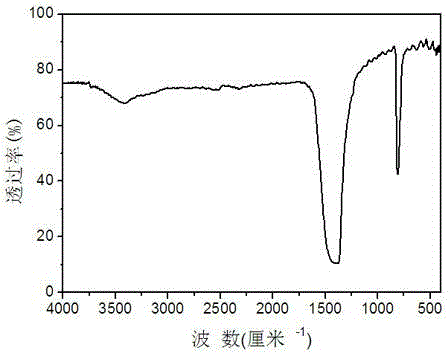

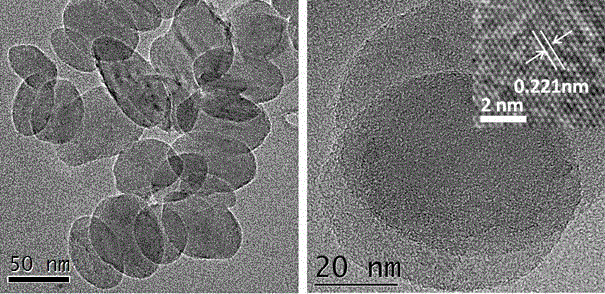

[0018] B with a mass ratio of 100:600:9 2 o 3 , CO(NH 2 ) 2 Mix it with copper nitrate and grind it into powder; take the mixed sample in a corundum magnetic boat, put it in a horizontal high-temperature tube furnace, and raise the temperature at a rate of 5-10°C / min to Keep at 1250°C for another 4-8 hours; take out the samples, wash them with deionized water, absolute ethanol, and 1mol / L dilute nitric acid, filter them with suction, soak them, and filter them with suction. After repeated several times, a milky white colloid is obtained. (Its crystal structure, infrared spectrum are respectively as figure 1 , 2 As shown, its morphology is as image 3 , 4 , 5 shown). The colloid concentration can reach 20 mg / mL.

Embodiment 1

[0020] B with a mass ratio of 100:600:9 2 o 3 , CO(NH 2 ) 2 Mix with copper nitrate and grind into powder; take the mixed sample in a corundum magnetic boat, then place it in a horizontal high-temperature tube furnace, and raise the temperature to 1250°C at a rate of 10°C / min under the protection of an ammonia atmosphere Keep it for another 4 hours; take out the samples and wash them with deionized water, absolute ethanol, and 1mol / L dilute nitric acid respectively, filter them with suction, soak them, and filter them with suction.

Embodiment 2

[0022] B with a mass ratio of 100:600:9 2 o 3 , CO(NH 2 ) 2 Mix with copper nitrate and grind into powder; take the mixed sample in a corundum magnetic boat, then place it in a horizontal high-temperature tube furnace, and raise the temperature to 1250°C at a rate of 8°C / min under the protection of an ammonia atmosphere Keep it for another 6 h; take out the samples and wash them with deionized water, absolute ethanol, and 1mol / L dilute nitric acid respectively, filter them with suction, soak them, and filter them with suction. After repeated several times, a milky white colloid is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com