Method for preparing fluorine-doped helical carbon nanotube

A technology of doping carbon nanotubes and fluorine, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., to achieve the effects of low production cost, easy processing, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Add 0.01mol nickel nitrate hexahydrate and 0.03mol citric acid monohydrate into a Erlenmeyer flask filled with 100ml of absolute ethanol, heat it in a water bath to 60°C and stir, keep it for 8 hours, then transfer it to a beaker, and put it in a beaker at 85°C After basic drying, it was completely dried at 175° C., and finally put into a muffle furnace for calcination at 375° C. for 4 hours to obtain nickel oxide nanoparticles.

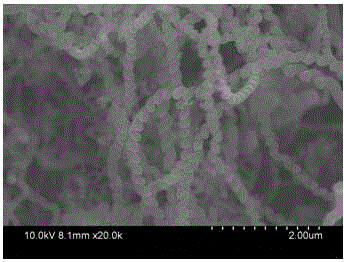

[0020] (2) Weigh 0.025 grams of nickel oxide nanoparticles prepared in step (1) and put them into a tube furnace with a pipe diameter of 50 mm in a porcelain boat, heat to 365 ° C and keep for 1 hour, then turn off the hydrogen and pass through acetylene (flow rate of 40ml / min) to heat to 550 ° C and keep it for 1 hour, finally turn off the acetylene and pass through argon, and drop to room temperature under the protection of argon to prepare spiral carbon nanotubes.

[0021] (3) The helical carbon nanotubes prepared in step (2) are weigh...

Embodiment 2

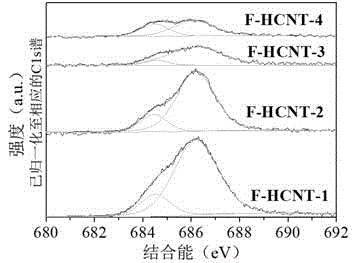

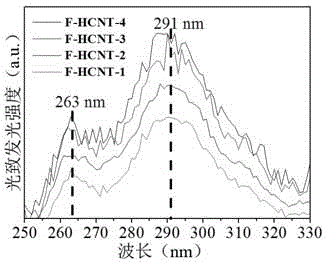

[0023] Change the mixing mass ratio of helical carbon nanotubes and xenon difluoride in step (3) of Example 1 to 1:7, and other conditions are completely the same as in Example 1 to obtain fluorine-doped helical carbon nanotubes F-HCNT -2.

Embodiment 3

[0025] Change the mixing mass ratio of helical carbon nanotubes and xenon difluoride in step (3) of Example 1 to 1:5, and other conditions are completely the same as in Example 1 to obtain fluorine-doped helical carbon nanotubes F-HCNT -3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com