A sediment passivation system suitable for aquatic ecological reconstruction and its construction technology

A construction technology and sediment technology, applied in water/sludge/sewage treatment, sludge treatment, runoff/rainwater treatment, etc., can solve the problem of pollutant migration pathway, thermodynamic and dynamic behavior, sediment Poor compression effect, increased total amount of pollutants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

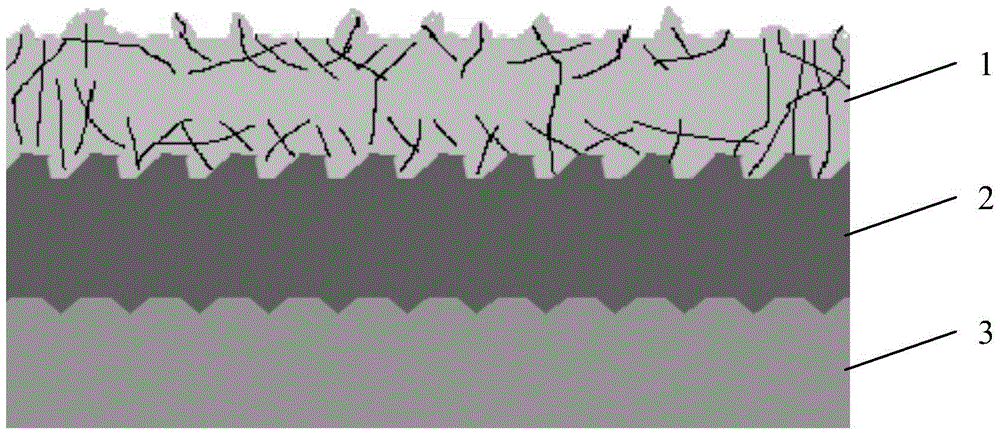

[0067] A sediment passivation system suitable for aquatic ecological reconstruction of the present invention is realized through the following steps:

[0068] S1: On the floating mud flat in the intertidal zone of the estuary, a cofferdam of about 3*12 meters is built at low tide to keep water for operation and observation. Use 300 orders of inferior hematite (ferric oxide) powder: bauxite (gibbsite type): salt-resistant polyacrylamide (for petroleum mud) fine powder=150:50:5, the three are mixed, add Appropriate water is converted into flocs, which are spread into the water body, and the flocs sink to the bottom mud, and the bottom mud is obviously compressed. Spread all over to form a lower layer about 3-5 cm thick.

[0069] The bagasse that has been soaked in lime water to remove lignin is used as plant fiber, and the middle layer material is plant fiber: high alumina cement: salt-resistant polyacrylamide weight ratio 2:3:0.03, salt-resistant polyacrylamide and high-alumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com