Biochar-based slow-release nitrogen fertilizer and preparation method thereof

A biochar and nitrogen fertilizer technology, which is applied in the direction of nitrogen fertilizer, ammonium salt fertilizer, fertilization device, etc., can solve the problems of not using biochar, etc., and achieve obvious effects of increasing production, wide application range, and good slow-release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

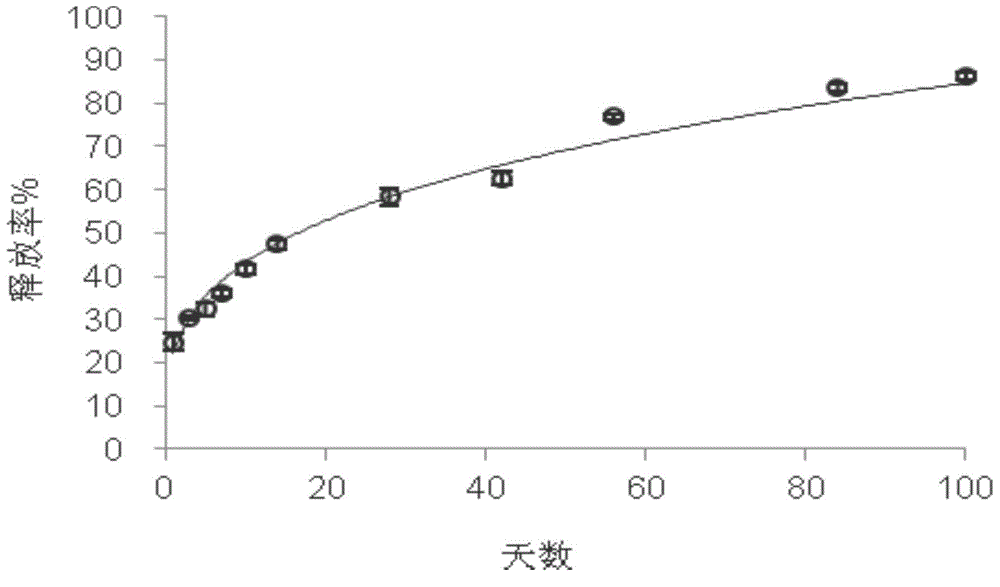

[0030] Example 1: Preparation of biochar-based slow-release nitrogen fertilizer and its release efficiency test

[0031] 1. Preparation of biochar-based slow-release nitrogen fertilizer:

[0032] 1) Biochar obtained by mixing agricultural straw and garden waste purchased on the market at 400°C (purchased from Biomass Gasification Engineering Company, Lijiachang Village, Weishanzhuang Town, Daxing District, Beijing, biochar with a nitrogen content of 1.25%, Available Potassium 1625mg·kg -1 , available phosphorus 238mg·kg -1 , exchangeable calcium 2.36g·kg -1 , exchangeable magnesium 0.74g·kg -1 , pH 10.84, CEC 13.0cmol kg -1 , EC (water-carbon ratio 10:1) 4325μs cm -1 ) 10kg, the urea with nitrogen content ≥ 46% bought by the fertilizer factory, the pulverized particle diameter after being pulverized respectively is that the qualities such as 20 mesh biochar and urea are fully mixed, and set aside;

[0033] 2) Pack the biochar and urea mixed uniformly in step 1) with a hi...

Embodiment 2

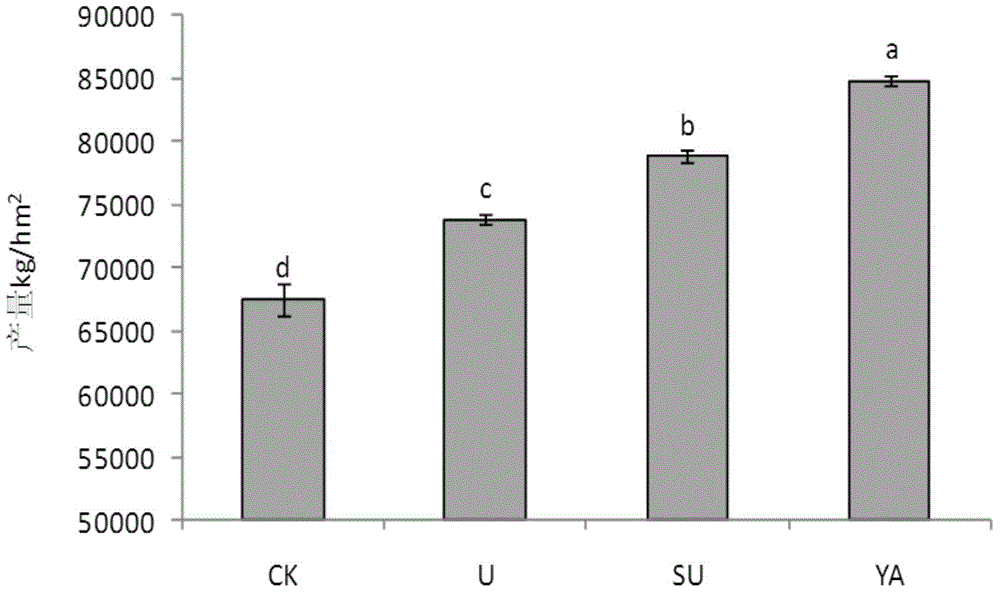

[0042] Example 2: Preparation of biochar-based slow-release nitrogen fertilizer and its fertilization effect test

[0043] 1. Preparation of biochar-based slow-release nitrogen fertilizer:

[0044]1) Biochar obtained by mixing agricultural straw and garden waste purchased on the market at 700°C (purchased from Biomass Gasification Engineering Company, Lijiachang Village, Weishanzhuang Town, Daxing District, Beijing, biochar with a nitrogen content of 1.25%, Available Potassium 1625mg·kg -1 , available phosphorus 238mg·kg -1 , exchangeable calcium 2.36g·kg -1 , exchangeable magnesium 0.74g·kg -1 , pH 10.84, CEC 13.0cmol kg -1 , EC (water-carbon ratio 10:1) 4325μs cm -1 ) 10kg, the urea with nitrogen content ≥ 46% bought by the fertilizer factory, the pulverized particle diameter after being pulverized respectively is that the qualities such as 20 mesh biochar and urea are fully mixed, and set aside;

[0045] 2) Put the biochar and urea mixed uniformly in step 1) into a hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com