A kind of preparation method of bazedoxifene acetate crystal form a

A technology of crystal form of xifene and acetic acid, which is applied in the field of preparation of crystal form A of bazedoxifene acetate, can solve the problems of no industrial production scale and easy transformation into form B, and achieve improved controllability and operation Improved repeatability and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

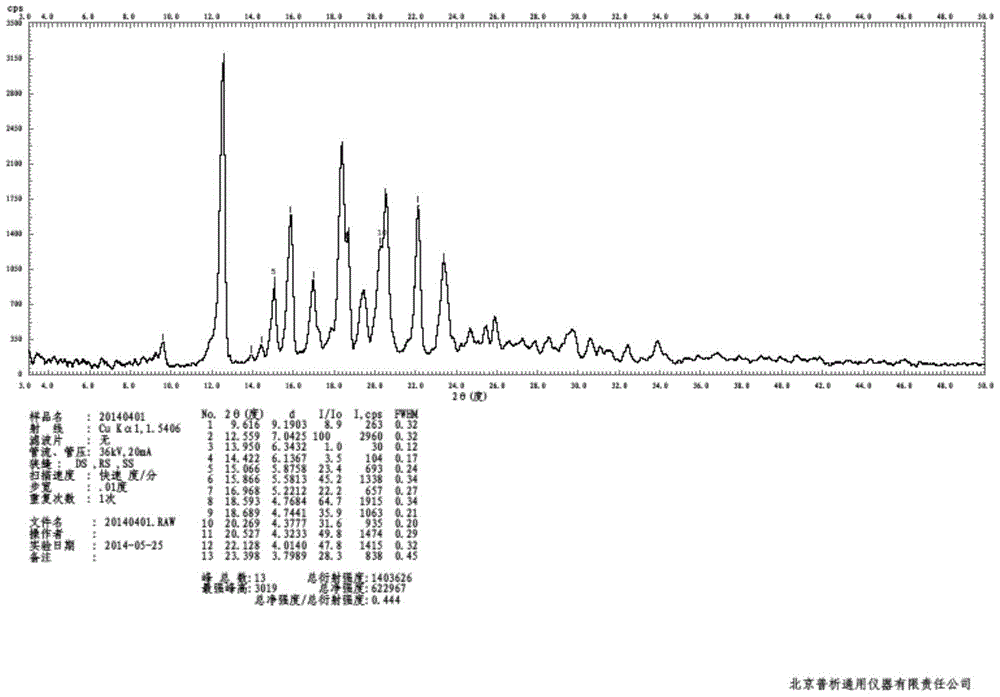

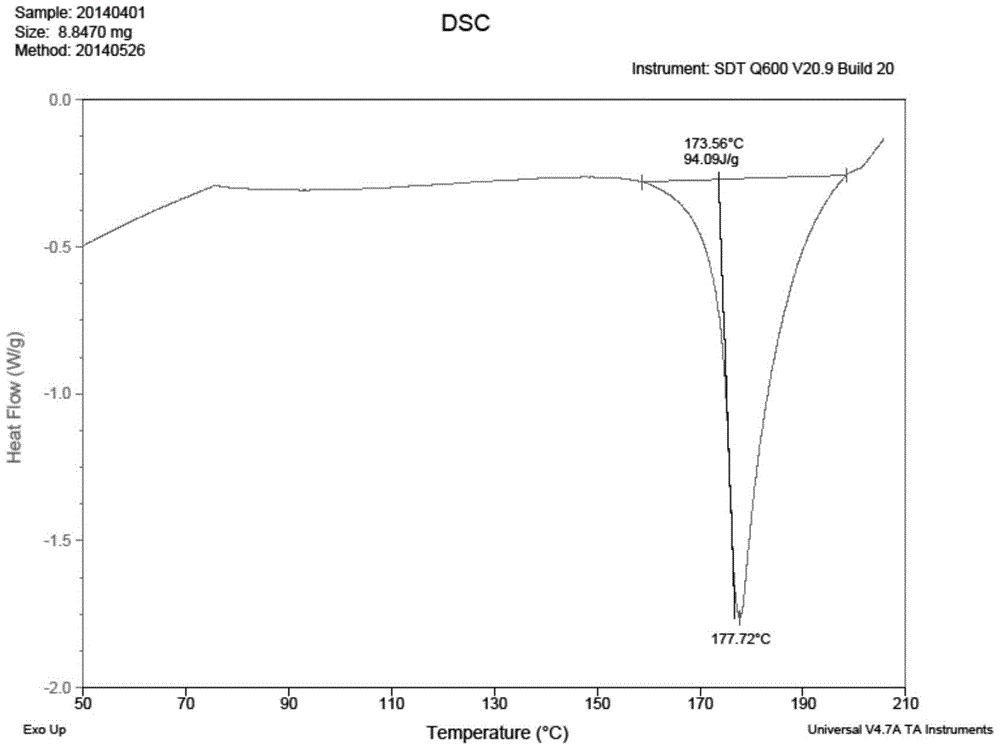

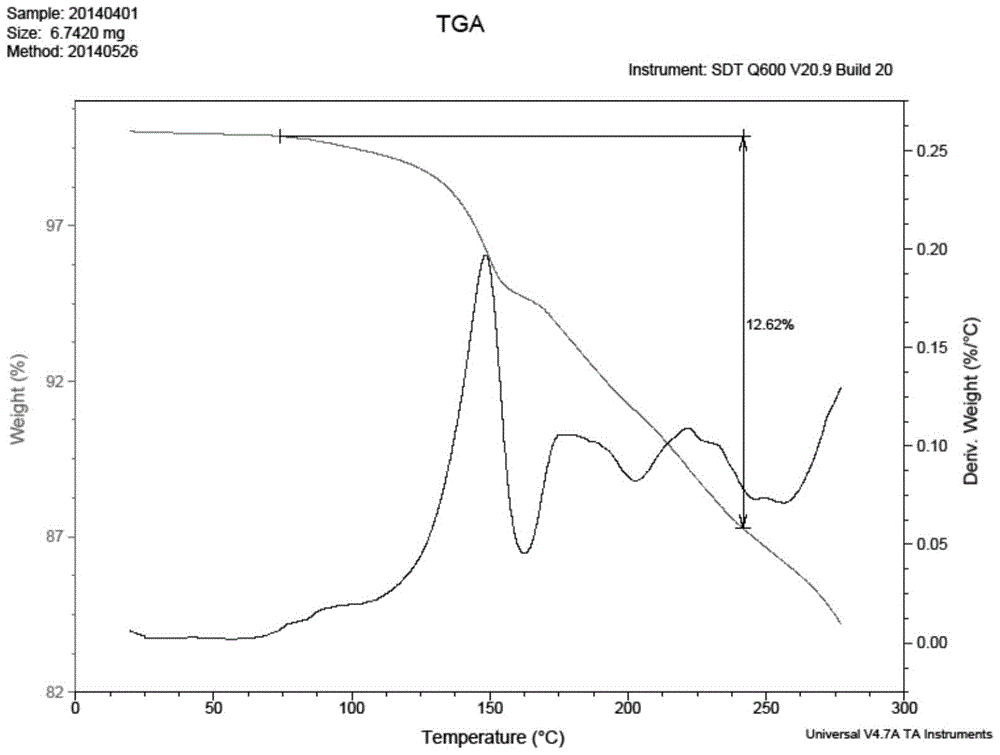

Image

Examples

Embodiment 1

[0083] The preparation of embodiment 1 bazedoxifene acetate crystal form A

[0084]

[0085] Weigh hexamethyleneimine benzyloxyindole (2kg), ammonium formate (0.58kg), 10% palladium carbon (0.2kg, moisture content 50%) and add in the reactor containing tetrahydrofuran (12L) , heated to 45-50°C and reacted for about 2-3 hours. After the reaction was complete, the palladium carbon was filtered off, the solution was cooled to 10-15°C, and then acetic acid (0.37kg) and methyl tert-butyl ether (10L ), the solution continued to stir for 12 hours at 10‐15 °C. Suction filtration and vacuum drying of the solid at 50° C. for 10 hours gave 1.12 kg of white powdery solid with a yield of 68.7%.

[0086] Weigh the crude form A (1kg) obtained above into a reactor containing tetrahydrofuran (8L), raise the temperature to 45-50°C under the protection of an inert gas, filter the solution after the solid is completely dissolved, and continue cooling the filtrate to 10-15°C , and then add me...

Embodiment 2

[0087] The preparation of embodiment 2 bazedoxifene acetate crystal form A

[0088] Weigh hexamethyleneimine benzyloxyindole (2kg), ammonium formate (0.58kg), 10% palladium carbon (0.1kg, water content 50%) and add in the reactor containing tetrahydrofuran (12L) , heated to 45-50°C and reacted for about 2-3 hours. After the reaction was complete, the palladium carbon was filtered off, the solution was cooled to 10-15°C, and then acetic acid (0.185kg) and methyl tert-butyl ether (5L ), the solution continued to stir for 12 hours at 10‐15 °C. Suction filtration, the solid was vacuum dried at 50°C for 10 hours to obtain the crude crystal form A.

[0089] Weigh the crude form A (1kg) obtained above into a reactor containing tetrahydrofuran (8L), raise the temperature to 45-50°C under the protection of an inert gas, filter the solution after the solid is completely dissolved, and continue cooling the filtrate to 10-15°C , and then add methyl tert-butyl ether (5L) in batches, and ...

Embodiment 3

[0090] The preparation of embodiment 3 bazedoxifene acetate crystal form A

[0091] Weigh hexamethyleneimine benzyloxyindole (2kg), ammonium formate (0.58kg), 10% palladium carbon (0.4kg, water content 50%) and join in the reactor containing tetrahydrofuran (12L) , heated to 45-50°C and reacted for about 2-3 hours. After the reaction was complete, the palladium carbon was filtered off, the solution was cooled to 10-15°C, and then acetic acid (0.185kg) and methyl tert-butyl ether (5L ), the solution continued to stir for 12 hours at 10‐15 °C. Suction filtration, the solid was vacuum dried at 50°C for 10 hours to obtain the crude crystal form A.

[0092] Weigh the crude form A (1kg) obtained above into a reactor containing tetrahydrofuran (8L), raise the temperature to 45-50°C under the protection of an inert gas, filter the solution after the solid is completely dissolved, and continue cooling the filtrate to 10-15°C , and then add methyl tert-butyl ether (5L) in batches, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com