Preparation method of organic vehicle olefin polymerization catalyst

A technology of olefin polymerization and organic carrier, which is applied in the field of organic carrier preparation, can solve the problems of large particle size and distribution, and achieve the effects of uniform particle size, easy filtration, and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

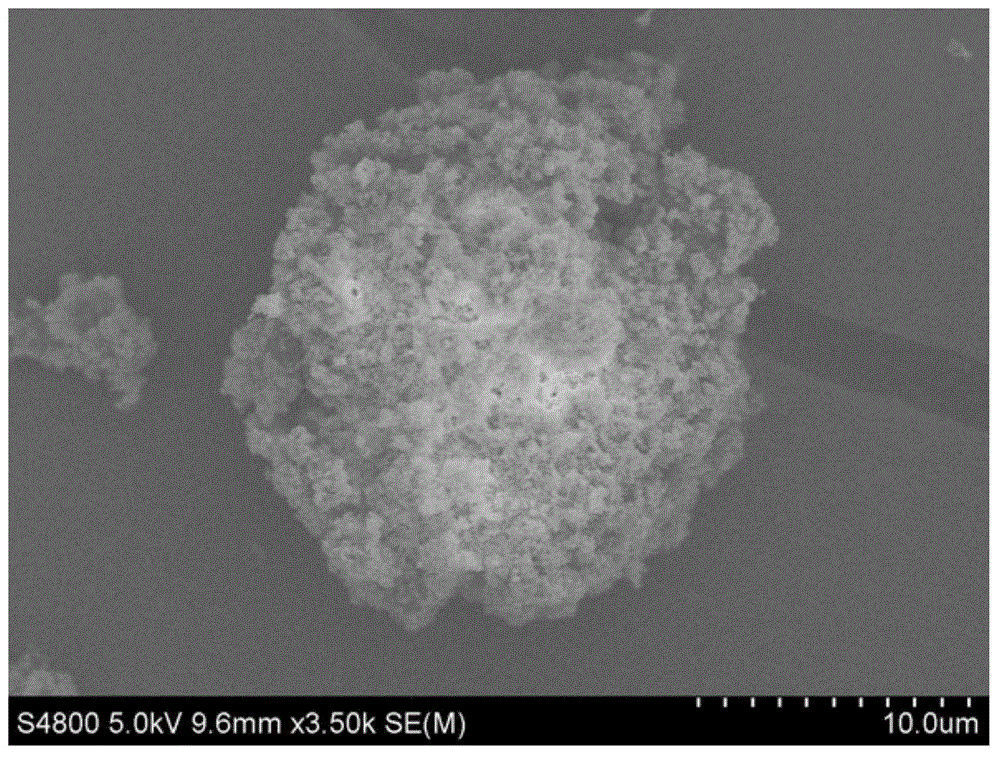

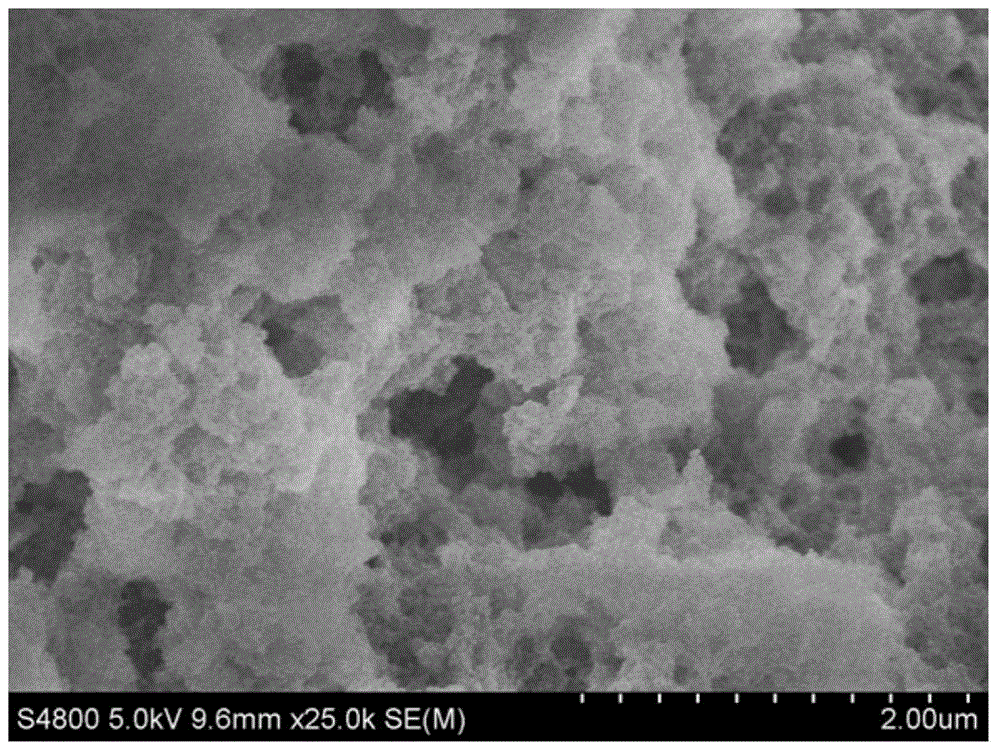

Image

Examples

Embodiment 1

[0035] This embodiment provides a method for preparing an organic carrier for an olefin polymerization catalyst, comprising the following steps:

[0036] In a 250mL glass reactor, add 108mL ethanol and 12mL deionized water;

[0037] Add 3.8g divinylbenzene (55wt%) and 2.4g hydroxyethyl methacrylate reaction monomer, stir at room temperature for 5min;

[0038] Add iron ferric oxide nanoparticles (particle size: 20nm) accounting for 5% of the total mass of the reaction monomers and polyvinyl alcohol (the degree of polymerization is 1788) accounting for 2% of the total mass of the reaction monomers, and stir for 1 hour at 50° C. Vinyl alcohol stabilizer dissolved;

[0039] Add AIBN accounting for 2% of the total mass of the reaction monomer, raise the temperature to 70°C, react for 3 hours, raise the temperature to 80°C, and react for 5 hours, the stirring speed is 360 rpm, using ethanol / water (1:1) Mixed solvent washes 3 times, uses 400 order 316 stainless steel filter net multi...

Embodiment 2

[0042] This embodiment provides a method for preparing an organic carrier for an olefin polymerization catalyst, comprising the following steps:

[0043] In a 250mL glass reactor, add 126mL ethanol and 14mL deionized water;

[0044] Add 4.6g divinylbenzene (55wt%) and 3.1g hydroxyethyl methacrylate (98wt%) reaction monomer, and stir at room temperature for 5min;

[0045] Add iron ferric oxide nanoparticles (20nm in particle size) accounting for 3% of the total mass of the reaction monomers and polyvinyl alcohol (1788 degree of polymerization) accounting for 2% of the total mass of the reaction monomers, stir at 50° C. for 1 h, and polymerize Vinyl alcohol stabilizer dissolved;

[0046] Add AIBN accounting for 2% of the total mass of the reaction monomer, raise the temperature to 70°C, react for 3 hours, then raise the temperature to 80°C, react for 5 hours, stir at 360 rpm, wash 3 times with ethanol, and dry 5.0 g of gray porous organic carrier A2-1 containing ferric oxide w...

Embodiment 3

[0049] This embodiment provides a method for preparing an organic carrier for an olefin polymerization catalyst, the steps of which are basically the same as those in Example 2, except that the amount of ferric iron tetroxide nanoparticles becomes 1.5% of the total mass of the reaction monomers, 4.0 g of porous organic carrier containing ferric oxide was prepared as A3-1.

[0050] Take 2.8g of the dried A3-1 carrier, use 20mL of 36.5% concentrated hydrochloric acid and 100mL of alcohol / water system acid solvent (mass ratio 1:1), wash at 70°C for 2h, the solution turns from gray black to yellow, filter Finally, wash 0.5h with a small amount of above-mentioned acid solvent, then wash 3 times with the solvent of alcohol / water (mass ratio 1:1) system, obtain 2.4g white porous P (DVB-co-HEMA) organic carrier A3 after filtering and drying -2.

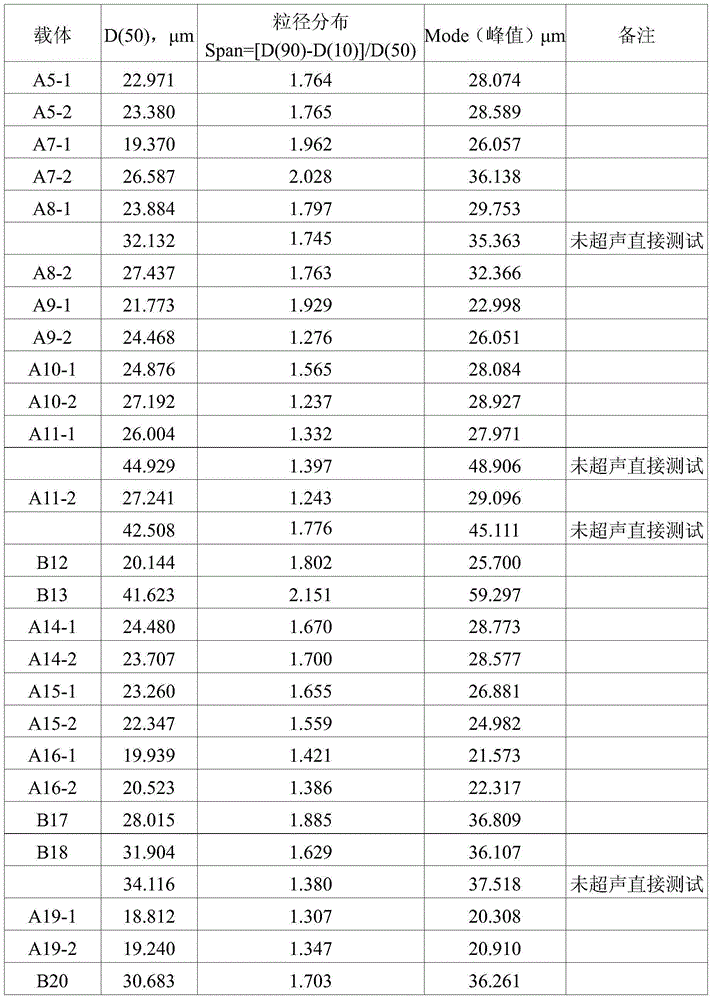

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com