A kind of environment-friendly water-based varnish for composite gold cardboard and preparation method thereof

An environmentally friendly, gold cardboard technology, applied in the direction of coating, etc., can solve the problems of small application range of solvent-based varnish, flocculation of water-based varnish, poor compatibility, etc., and achieve excellent adhesion fastness, low VOC emission, and compatibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

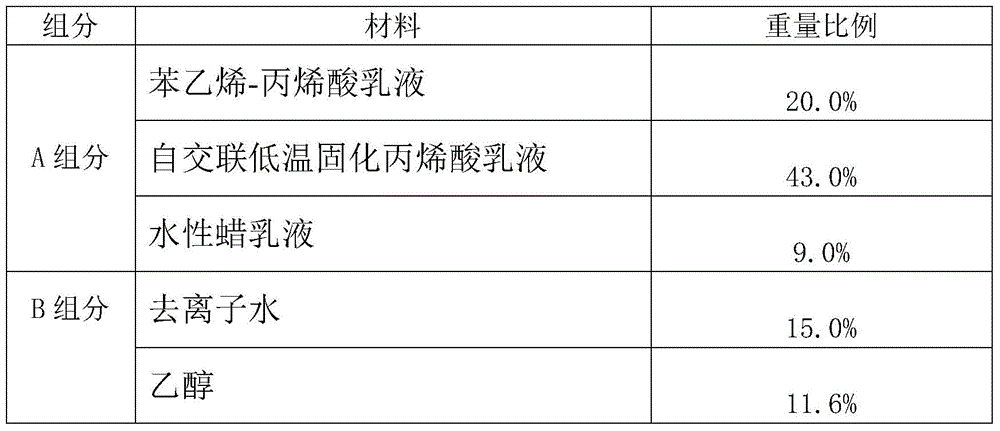

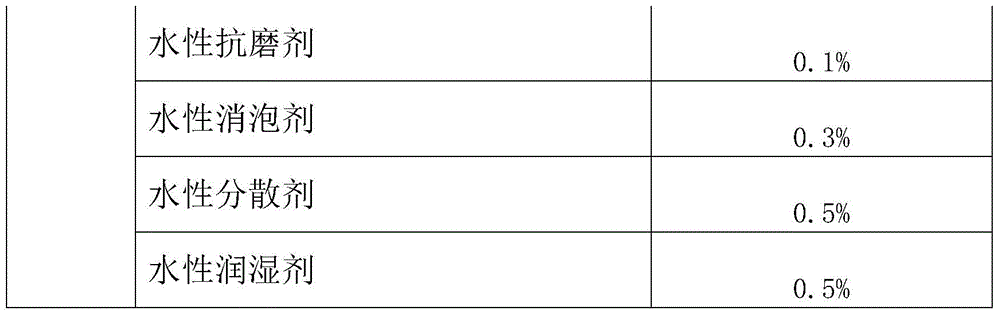

Embodiment 1

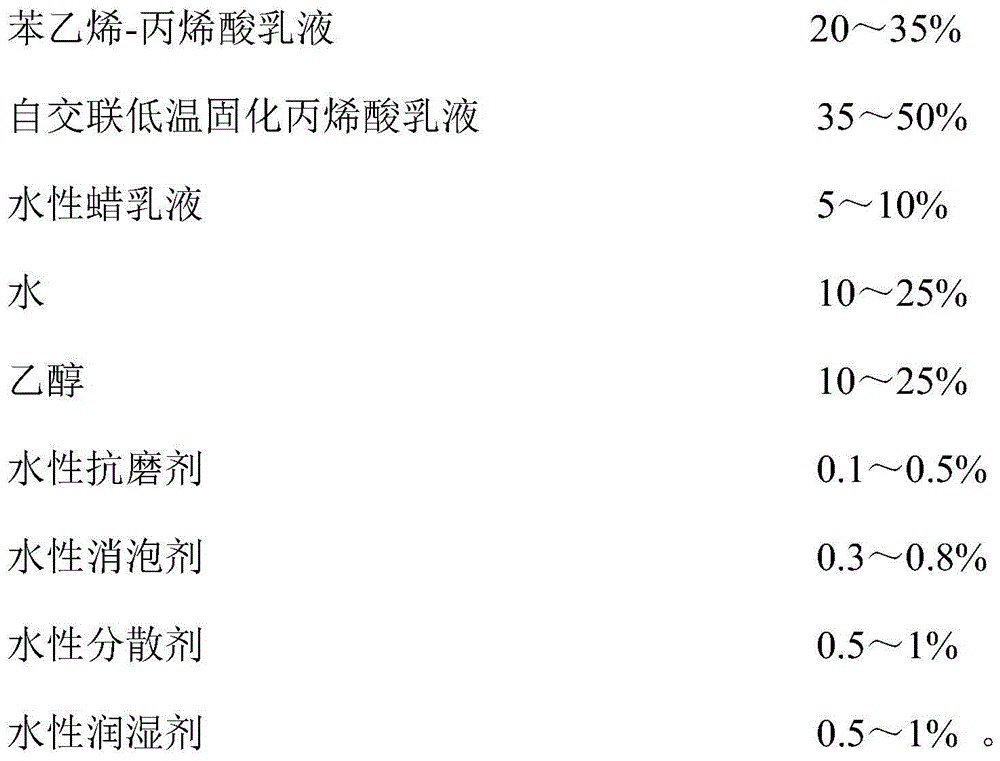

[0057] A kind of environment-friendly water-based varnish for composite gold cardboard, by weight percentage, its formula consists of:

[0058]

[0059]

[0060] The preparation method of this kind of composite gold cardboard with environment-friendly water-based varnish is as follows:

[0061] 1) Configure component A: styrene-acrylic emulsion, self-crosslinking low-temperature curing acrylic emulsion, and water-based wax emulsion are added to the dispersion tank according to the formula ratio, start the agitator, and stir at 400 rpm for 10 minutes;

[0062] 2) Configure component B: Add deionized water, ethanol, water-based anti-wear agent, water-based defoamer, water-based dispersant, and water-based wetting agent into the mixing tank according to the proportion, start the agitator, and rotate at 400 rpm Stir for 12 minutes;

[0063] 3) Mixing: Pump the uniformly stirred component B into the dispersion tank, mix with component A and stir at 400 rpm for 15 minutes;

...

Embodiment 2

[0065] A kind of environment-friendly water-based varnish for composite gold cardboard, by weight percentage, its formula consists of:

[0066]

[0067]

[0068] The preparation method of this kind of composite gold cardboard with environment-friendly water-based varnish is as follows:

[0069] 1) Configure component A: Add styrene-acrylic emulsion, self-crosslinking low-temperature curing acrylic emulsion, and water-based wax emulsion into the dispersion tank according to the formula ratio, start the agitator, and stir at 350 rpm for 15 minutes;

[0070] 2) Configure component B: add deionized water, ethanol, water-based anti-wear agent, water-based defoamer, water-based dispersant, and water-based wetting agent into the mixing tank according to the proportion, start the agitator, and rotate at 350 rpm Stir for 15 minutes;

[0071] 3) Mixing: pump the uniformly stirred component B into the dispersion tank, mix with component A and stir at 350 rpm for 20 minutes;

[00...

Embodiment 3

[0074] A kind of environment-friendly water-based varnish for composite gold cardboard, by weight percentage, its formula consists of:

[0075]

[0076]

[0077] The preparation method of this kind of composite gold cardboard with environment-friendly water-based varnish is as follows:

[0078] 1) Configure component A: styrene-acrylic emulsion, self-crosslinking low-temperature curing acrylic emulsion, and water-based wax emulsion are added to the dispersion tank according to the formula ratio, start the agitator, and stir at 450 rpm for 18 minutes;

[0079] 2) Configure component B: Add deionized water, ethanol, water-based anti-wear agent, water-based defoamer, water-based dispersant, and water-based wetting agent into the mixing tank according to the proportion, start the agitator, and rotate at 450 rpm Stir for 20 minutes;

[0080] 3) Mixing: Pump the uniformly stirred component B into the dispersion tank, mix with component A and stir at 450 rpm for 15 minutes;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com