Dust suppressant for enhancing effect of permeating and wetting dust particles and coal bodies

A dust suppressant and coal body technology, which is applied in the field of coal mine suppression of dust particles and coal body wetting, can solve the problems of dust accumulation, high dust generation in tunneling roadways, and difficulty in ventilation and dust removal in tunneling roadways

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

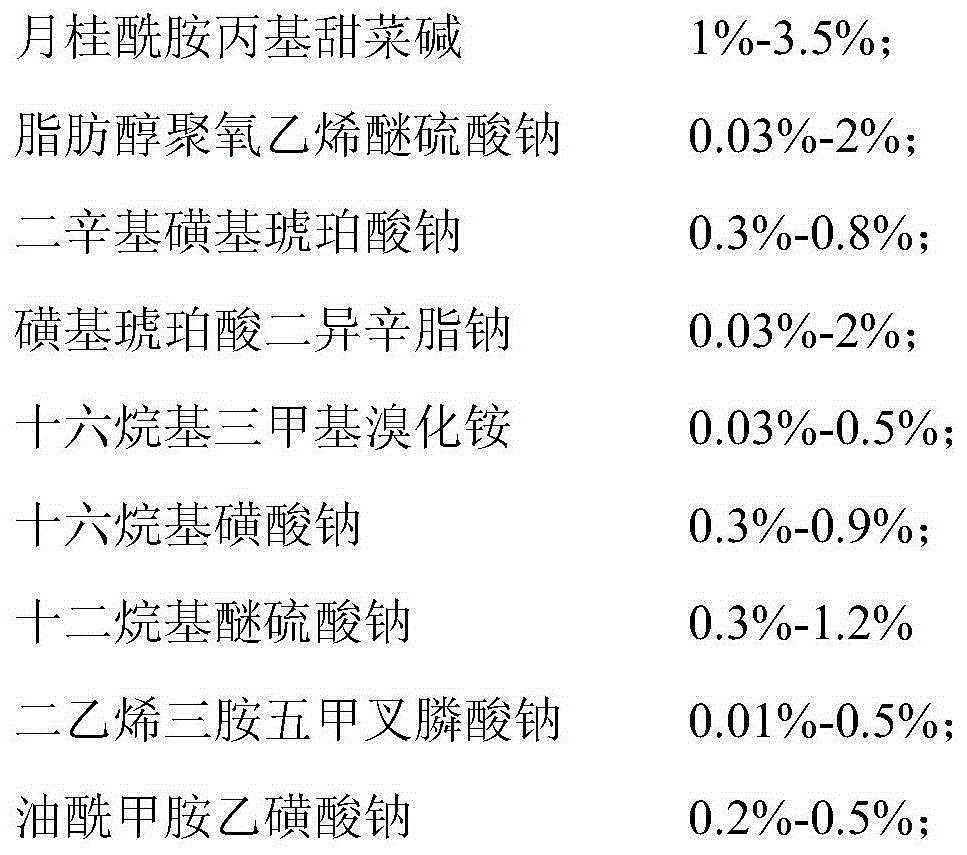

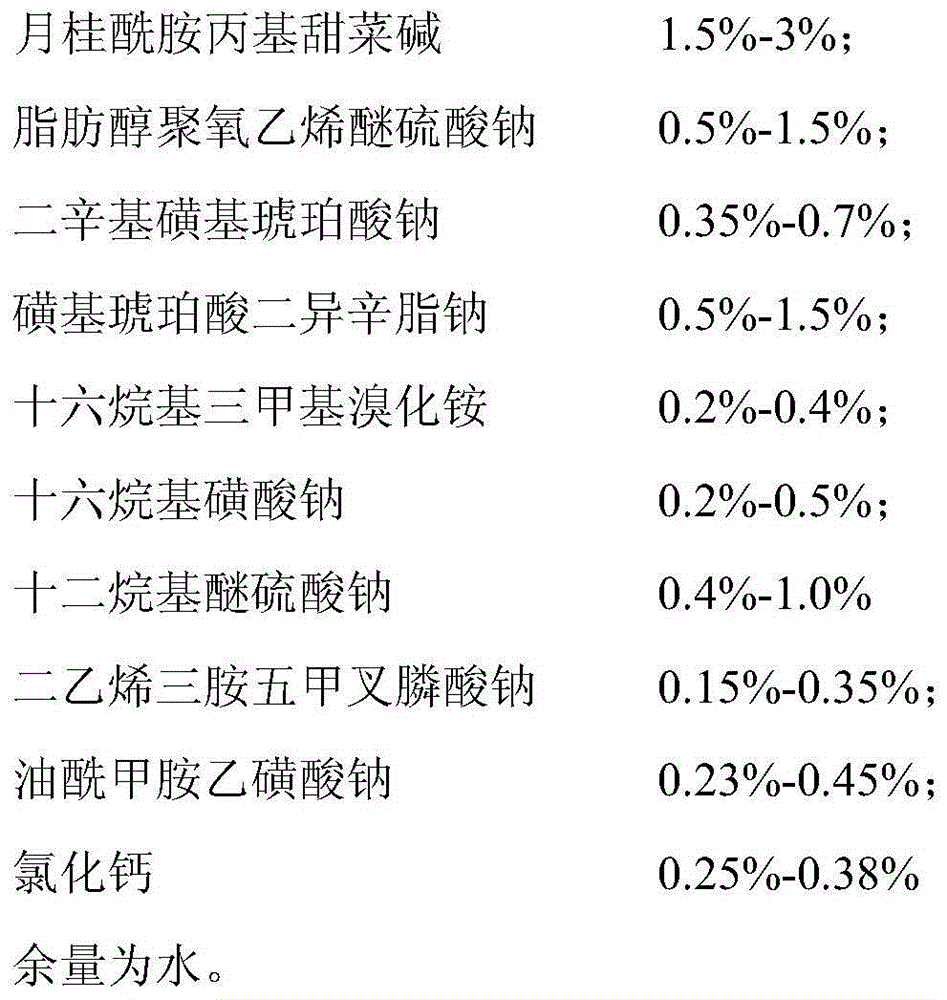

[0024] Add 1g lauryl amidopropyl betaine, 0.03g fatty alcohol polyoxyethylene ether sodium sulfate, 0.3g dioctyl sodium sulfosuccinate, 0.03g dioctyl sodium sulfosuccinate, 0.03g ten Hexaalkyltrimethylammonium bromide, 0.3g sodium hexadecylsulfonate, 0.3g sodium lauryl ether sulfate, 0.01g sodium diethylenetriaminepentamethylene phosphonate, 0.2g oleoylmethylamide ethyl Sodium Sulfonate and 0.2g Calcium Chloride and allow to mix well. Among them, according to weight percentage: lauryl amidopropyl betaine 1%, sodium fatty alcohol polyoxyethylene ether sulfate 0.03%, dioctyl sodium sulfosuccinate 0.3%, dioctyl sodium sulfosuccinate 0.03%, cetyl Alkyltrimethylammonium bromide 0.03%, Sodium Cetyl Sulfonate 0.3%, Sodium Lauryl Ether Sulfate 0.3%, Sodium Diethylene Triamine Pentamethylene Phosphonate 0.01%, Oleoyl Methamide Ethylsulfonate Sodium Acid 0.2% and Calcium Chloride 0.2%.

Embodiment 2

[0026] Add 1.5g lauryl amidopropyl betaine, 0.5g fatty alcohol polyoxyethylene ether sodium sulfate, 0.35g dioctyl sodium sulfosuccinate, 0.5g dioxoctyl sodium sulfosuccinate, 0.2g to 95.72g water Cetyltrimethylammonium bromide, 0.2g sodium cetylsulfonate, 0.4g sodium lauryl ether sulfate, 0.15g sodium diethylenetriaminepentamethylene phosphonate, 0.23g oleoylmethylamide sodium ethanesulfonate and 0.25g calcium chloride and allow to mix well. In terms of weight percentage: lauryl amidopropyl betaine 1.5%, sodium fatty alcohol polyoxyethylene ether sulfate 0.5%, dioctyl sodium sulfosuccinate 0.35%, dioctyl sodium sulfosuccinate 0.5%, cetyl Alkyl Trimethyl Ammonium Bromide 0.2%, Sodium Cetyl Sulfonate 0.2%, Sodium Lauryl Ether Sulfate 0.4%, Sodium Diethylene Triamine Pentamethylene Phosphonate 0.15%, Oleoyl Methamide Ethylsulfonate Sodium Chloride 0.23% and Calcium Chloride 0.25%.

Embodiment 3

[0028] Add 2.1g lauryl amidopropyl betaine, 1g fatty alcohol polyoxyethylene ether sodium sulfate, 0.4g dioctyl sodium sulfosuccinate, 1g dioctyl sodium sulfosuccinate, 0.25g hexadecyl Alkyltrimethylammonium bromide, 0.3g sodium cetylsulfonate, 0.5g sodium lauryl ether sulfate, 0.26g sodium diethylenetriaminepentamethylene phosphonate, 0.25g oleoylmethylamide ethylsulfonate sodium chloride and 0.3g calcium chloride and mix well. In terms of weight percentage: lauryl amidopropyl betaine 2.1%, sodium fatty alcohol polyoxyethylene ether sulfate 1%, dioctyl sodium sulfosuccinate 0.4%, dioctyl sodium sulfosuccinate 1%, cetyl Alkyl trimethyl ammonium bromide 0.25%, sodium cetyl sulfonate 0.3%, sodium lauryl ether sulfate 0.5%, sodium diethylene triamine pentamethylene phosphonate 0.26%, oleamide ethyl sulfonate Sodium Chloride 0.25% and Calcium Chloride 0.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com