Biological gold extraction process of antimony-bearing complex refractory gold ore and microorganism used in same

A technology of microorganisms and gold mines, which is applied in the biological gold extraction process and the field of microorganisms used, can solve the problems of large consumption of sodium cyanide and low gold extraction rate, and achieve the advantages of reduced adsorption activity, wide temperature resistance range, and significant economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Isolation and screening of bacterial colonies

[0026] 1. Sample source

[0027] The sample came from the acid pit water of a complex gold mine containing antimony in Hezuo City, Gansu Province.

[0028] 2. Separation and purification of acidithiobacillus ferrooxidans ZJ-ZZG-1

[0029] Take 50mL of raw water and inoculate into 200mL of 9K liquid culture based on a 500ml Erlenmeyer flask, shake and cultivate in a constant temperature shaker at 35°C at 170rpm for 6-10d, use a 0.45μm organic microporous filter to remove the reddish-brown precipitate in the solution, and then Centrifuge the obtained filtrate in a high-speed centrifuge at 10,000 rpm for 20 minutes, collect the milky white precipitate at the bottom, which is the bacterial aggregate, and finally dilute it with deionized water to obtain a bacterial suspension, which is the mixed culture of acidophilic bacteria. The obtained bacterial mixture Continue to enrich for 3 to 4 generations, and then dilute...

Embodiment 2

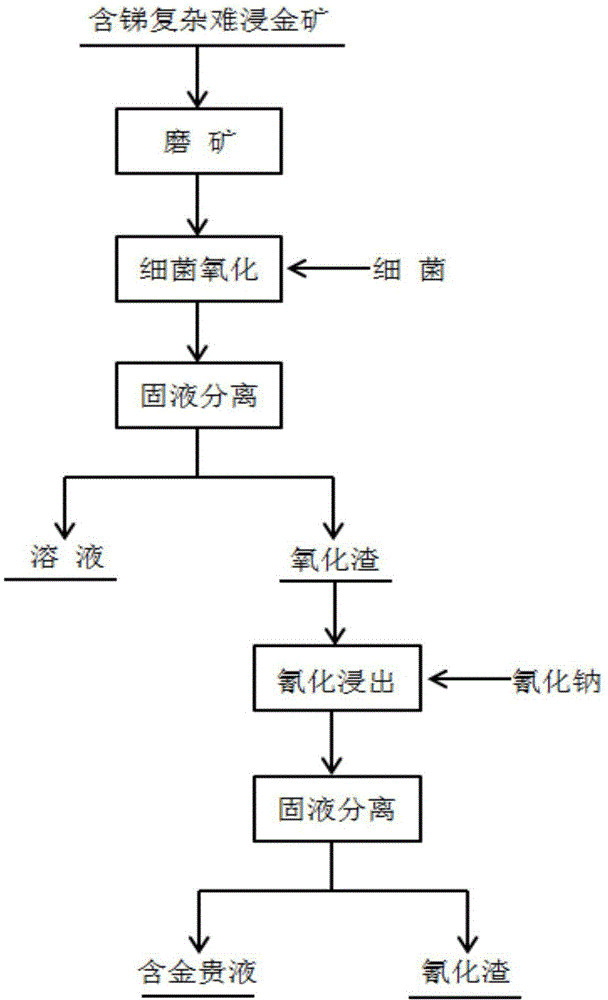

[0031] Embodiment 2 biological gold extraction process

[0032] 1. Subjects

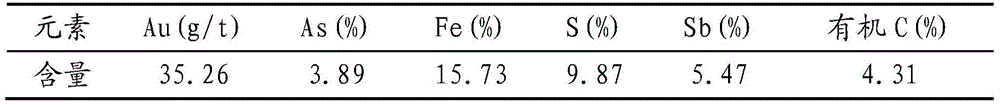

[0033] A typical antimony complex refractory gold ore, the gold concentrate contains high content of antimony, arsenic and organic carbon, and the gold is disseminated in microscopic or submicroscopic form in pyrite, arsenopyrite and stibnite to form inclusions , The gold concentrate is leached by conventional cyanide, the consumption of sodium cyanide is 47.6kg / t, and the leaching rate of gold is only 21.73%. The chemical analysis of the main elements of the gold concentrate is shown in Table 1 below:

[0034] Table 1 Chemical analysis of main elements of gold concentrate

[0035]

[0036] 2. Experimental methods and results

[0037] In an oxidation tank equipped with a stirring device, inoculate acidithiobacillus ferrooxidans ZJ-ZZG-1 (preservation number CCTCC NO: M2014120) into 9K medium for expanded culture, with an inoculum size of 10% and an air volume of 0.2m 3 / h, the stirring rate was...

Embodiment 3

[0040] Embodiment 3 biological gold extraction process

[0041] 1. Subjects

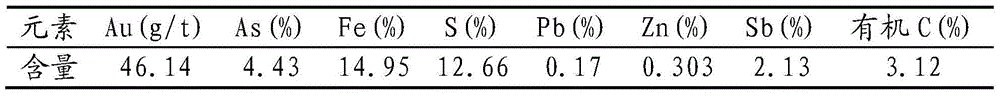

[0042] A complex refractory gold mine containing antimony. The chemical analysis of the main elements of the gold concentrate is shown in Table 2. The gold concentrate is leached by conventional cyanide, the consumption of sodium cyanide is 33.57kg / t, and the gold leaching rate is 38.92%.

[0043] Table 2 Chemical analysis of main elements of gold concentrate

[0044]

[0045] 2. Experimental methods and results

[0046] Inoculate CCTCC NO: M2014120 bacteria into 9K medium in an oxidation tank equipped with a stirring device for expanded culture, the inoculation amount is 20%, and the aeration amount is 0.4m 3 / h, the stirring rate is 1000 rpm, the culture temperature is 35°C, the pH value of the culture solution is 2.0, and the culture time is 36 hours.

[0047] Add the gold concentrate to the bacterial culture solution to make the slurry concentration 20wt%, inflate and stir with air, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com