A kind of environment-friendly organic-inorganic hybrid aluminum alloy primer and preparation method thereof

An environmentally friendly, aluminum alloy technology, applied in the direction of metal material coating process, etc., can solve the problem of no chromate-free conversion coating or primer, etc., to improve workability and storage, good environmental performance, improve The effect of overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

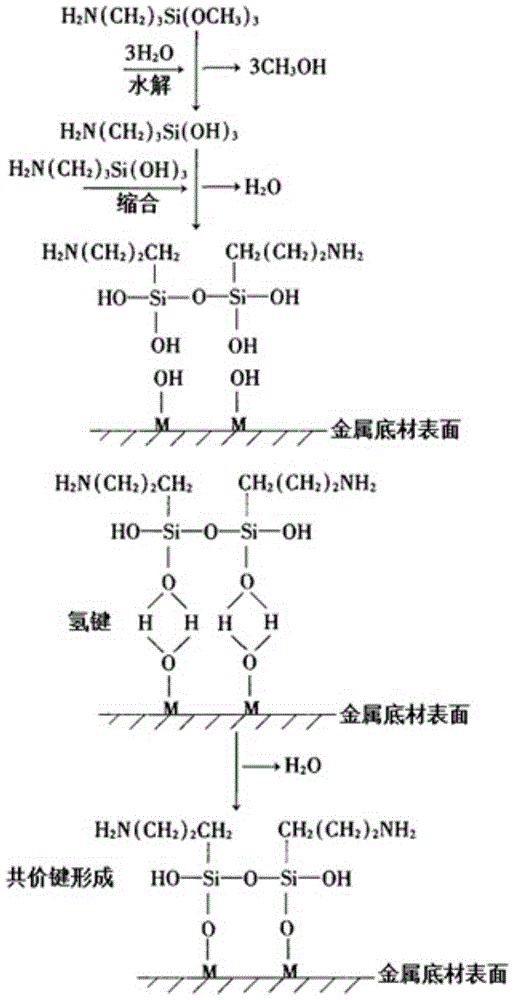

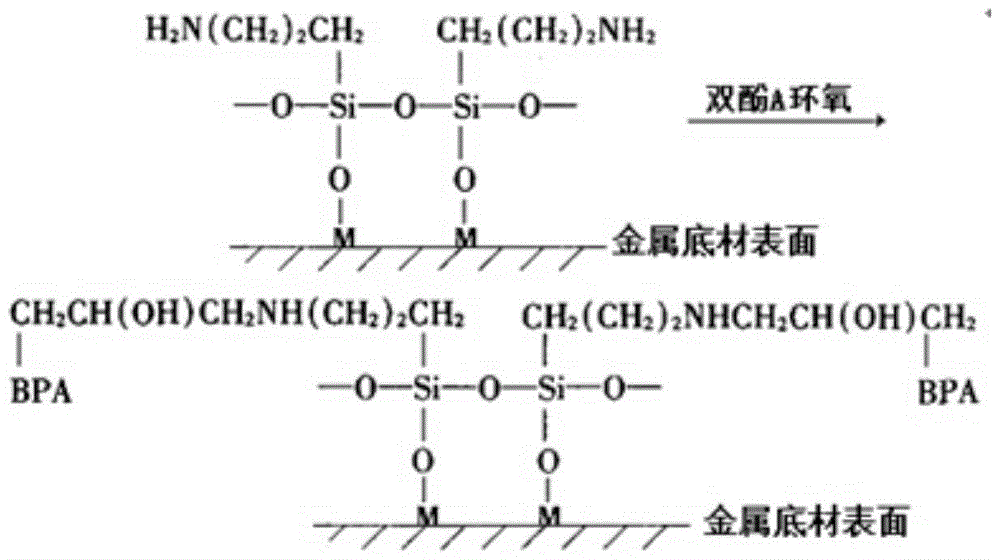

Method used

Image

Examples

Embodiment 1

[0031] Weigh each component according to the following mass percentages:

[0032]

[0033] The above-mentioned ethyl orthosilicate is ethyl silicate-40 from Jiangsu Changyu Chemical Co., Ltd.; ethanol, isopropanol and n-butanol are commercially available industrial grade products; hydrochloric acid is from Tianjin Kemiou Chemical Reagent Co., Ltd. Analytical pure hydrochloric acid reagent, HCl content is 36% ~ 38%; silane coupling agent is γ-aminopropyltriethoxysilane (γ-APS) Z-6011 from Dow Corning; triethylamine is from Tianjin Guangcheng Chemical Reagent Co., Ltd. The company's analytical reagents; polyvinyl butyral is WACKER's BN18.

[0034] Its preparation method is as follows:

[0035] Step 1: Put tetraethyl orthosilicate and 80% by mass (ethanol, isopropanol and n-butanol) mixed solvent into a reaction tank, stir evenly, heat to 60° C. in a water bath, and continue to stir rapidly. Add hydrochloric acid into distilled water and mix evenly to obtain hydrochloric aci...

Embodiment 2

[0043] Weigh each component according to the following mass percentages:

[0044]

[0045] The above-mentioned ethyl orthosilicate is ethyl silicate-32 from Jiangsu Changyu Chemical Co., Ltd.; ethanol, isopropanol and n-butanol are commercially available industrial grade products; hydrochloric acid is from Tianjin Kemiou Chemical Reagent Co., Ltd. Analytical pure hydrochloric acid reagent, HCl content is 36% ~ 38%; silane coupling agent is aminosilane KH550 of Nanjing Nengde Chemical; triethylamine is analytical reagent of Tianjin Guangcheng Chemical Reagent Co., Ltd.; polyvinyl butyral It is BL18 of WACKER company.

[0046] The preparation method is the same as in Example 1.

Embodiment 3

[0048] Weigh each component according to the following mass percentages:

[0049]

[0050]

[0051] The above-mentioned ethyl orthosilicate is ethyl silicate-40 from Jiangsu Changyu Chemical Co., Ltd.; ethanol, isopropanol and n-butanol are commercially available industrial grade products; hydrochloric acid is from Tianjin Kemiou Chemical Reagent Co., Ltd. Analytical pure hydrochloric acid reagent, the HCl content is 36% to 38%; the silane coupling agent is Dow Corning’s γ-aminopropyl triethoxysilane (γ-APS) Z-6011; triethylamine is Tianjin Guangcheng Chemical Reagent Co., Ltd. The company's analytical reagents; polyvinyl butyral is WACKER's BN18.

[0052] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com