Feed for improving quality of large yellow croakers, and feeding method of feed

A technology of quality improvement and quality improver, which is applied in animal feed, animal feed, fish farming, etc., can solve the problems of poor flavor of fish and shrimp products, affecting commodity prices and sustainable development, and poor quality of artificially farmed fish, etc., to achieve Improving animal production performance, increasing feed utilization, and increasing market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

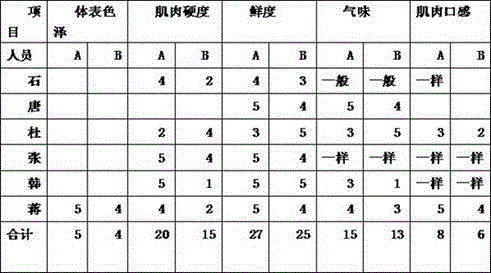

[0017] Experimental results of quality improvement of large yellow croaker

[0018] 1. Improve feed preparation. The ingredients are mixed according to the following weight percentages: 20% imported fish meal, 17% fresh fish paste, 9% shrimp powder, 3% scallop powder, 5% fermented soybean meal, 9% peeled soybean meal, 3% yeast protein, 1% soybean lecithin, Calcium dihydrogen phosphate 1%, high-gluten flour 20%, multivitamin 2.0%, quality improver 2.0%, fish oil 8%. Among them, the quality improver is composed of seaweed extract, cysteine hydrochloride and collagen small peptide at a ratio of 1.5:1:1, the seaweed extract is composed of brown algae extract and salina extract at a ratio of 3:2, and collagen small peptide It is a mixture of collagen peptides of different molecular weights with a molecular weight less than 4.5KDa formed by hydrolysis of collagen derived from terrestrial animals.

[0019] Second, improve the feeding of feed. The juvenile stage is fed 3 times a ...

Embodiment 2

[0042] The ingredients of large yellow croaker quality improvement feed are as follows: 22% imported fish meal, 20.2% fresh fish paste, 8% shrimp meal, 4% scallop meal, 9.5% fermented soybean meal, 6% peeled soybean meal, 3% yeast protein, soybean Phospholipid 1.2%, calcium dihydrogen phosphate 1.3%, high-gluten flour 16.5%, multivitamin 1.1%, quality improver 1.2%, fish oil 6%. Among them, the quality improver is composed of seaweed extract, cysteine hydrochloride and small collagen peptide in a ratio of 1:1:1.

[0043]Further, the quality improver seaweed extract is composed of brown algae extract, salina extract, and microalgae extract at a ratio of 1:1:1. Collagen small peptides are formed after hydrolysis of collagen with different molecular weights less than 3.5KDa. sized collagen peptide blend.

[0044] The feeding method of large yellow croaker quality-improved feed of the present invention is that juvenile stage is fed 3 times every day during the day, and the time...

Embodiment 3

[0046] The ingredients of large yellow croaker quality improvement feed are as follows: 19% imported fish meal, 18% fresh fish paste, 8.5% shrimp meal, 3.5% scallop meal, 4.8% fermented soybean meal, 6.4% peeled soybean meal, 6.5% yeast protein, soybean Phospholipid 4.6%, calcium dihydrogen phosphate 1.2%, high-gluten flour 19.5%, multivitamin 1.6%, quality improver 1.25%, fish oil 5.15%. Among them, the quality improver is composed of seaweed extract, cysteine hydrochloride and small collagen peptide at a ratio of 0.6:1:1.

[0047] Further, the quality improver seaweed extract is composed of brown algae extract and salina extract at a ratio of 1:1.25, and the small collagen peptide is a mixture of collagen peptides of different molecular weights with a molecular weight less than 2.8KDa formed after collagen hydrolysis.

[0048] The feeding method of large yellow croaker quality-improving feed of the present invention is that juvenile stage is fed 3 times every day during th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com