Production method of rice noodles added with plant ash leachate

A plant ash leaching solution and a technology for making it, which is applied in the field of food processing, can solve the problems of inconvenient storage and short shelf life of rice noodles, and achieve the effects of not being easy to break and prolonging the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

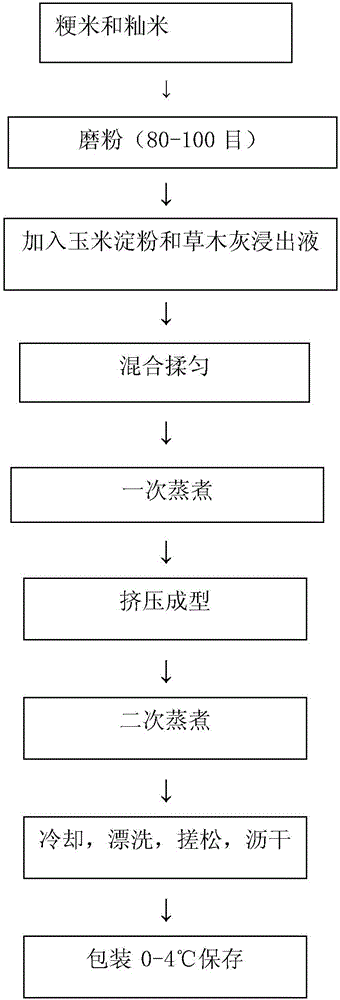

Method used

Image

Examples

Embodiment 1

[0038] (1) Preparation of plant ash extract: mix 100g of soybean stalk ash with 2000ml of pure water, soak in an open container at a temperature of 20-30°C for 48 hours, stir once every 12 hours during soaking, centrifuge after soaking, and filter to remove sediment and floating matter , collecting the filtrate as soybean stalk ash leachate;

[0039] (2) Making rice noodles: take 500g of 80-100 mesh japonica rice noodles and 1500g 80-100 mesh of indica rice noodles, mix them evenly to obtain mixed rice noodles, add 360g cornstarch and 944ml soybean stalk ash leachate to the mixed rice noodles, stir evenly, and mix to form Wet noodles, put the wet noodles on the pre-laid 3 layers of gauze and steam on the steaming plate heated to boiling for 20 minutes, so that the starch is fully gelatinized, and pour the steamed rice noodles into the rice noodles with an outlet aperture of 2.5mm while it is hot Extrude powder in the molding machine, cut off the extruded vermicelli according t...

Embodiment 2

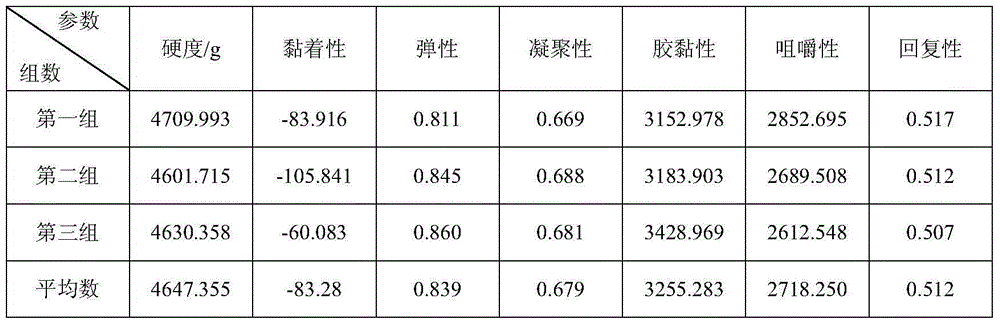

[0045] Operate according to the steps of Example 1, the difference is that the soybean stalk ash is changed to tea stick ash, and other parameter conditions remain unchanged, and wet rice noodles are obtained, and the texture analysis is carried out according to the method of Example 1, and each test is repeated 3 times. See Table 3 for the three sets of data results and average values of the three tests.

Embodiment 3

[0047] Operate according to the steps of Example 1, the difference is that the soybean stalk ash is changed to Eurum ash, and other parameters and conditions remain unchanged, and wet rice noodles are obtained. The texture analysis is carried out according to the method of Example 1, and each test is repeated 3 times. , the three sets of data results and average values of the three tests are shown in Table 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com