Adamantane derivative, preparation method and application in epoxy resin

A technology of epoxy resin and adamantane, which is applied in the application field of the above-mentioned adamantane derivatives in resins, can solve problems such as the reduction of electrical properties, aging resistance and mechanical properties, and achieve the effect of excellent thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] The present invention will be described in more detail below through specific examples, but the present invention is not limited to these examples. The resin compositions and comparative examples were evaluated by the following characterization methods.

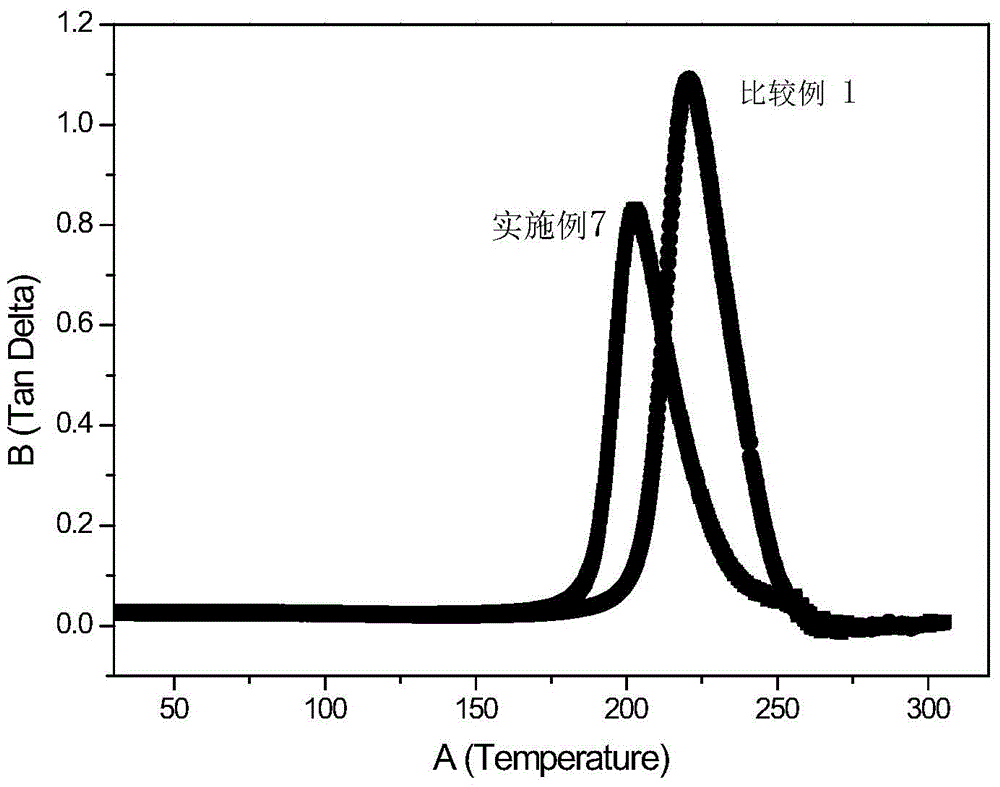

[0047] (1) Glass transition temperature test

[0048] Using dynamic thermomechanical analysis (Q800-DMA, manufactured by TA Company in the United States), a 60mm*5mm*2mm cured resin sample is used at an amplitude of 9um, a frequency of 1HZ, and a range of 30-350°C at 5°C / min. Its temperature rises to obtain the maximum value of tanδ as its glass transition temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com