Alkyne-ketone intermediate based conjugated high-molecular polymer as well as preparation method and application thereof

A conjugated polymer and polymer technology, which is applied in the field of organic polymer optoelectronic materials to achieve the effects of high polymer yield, high regional and stereoselectivity, and high molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

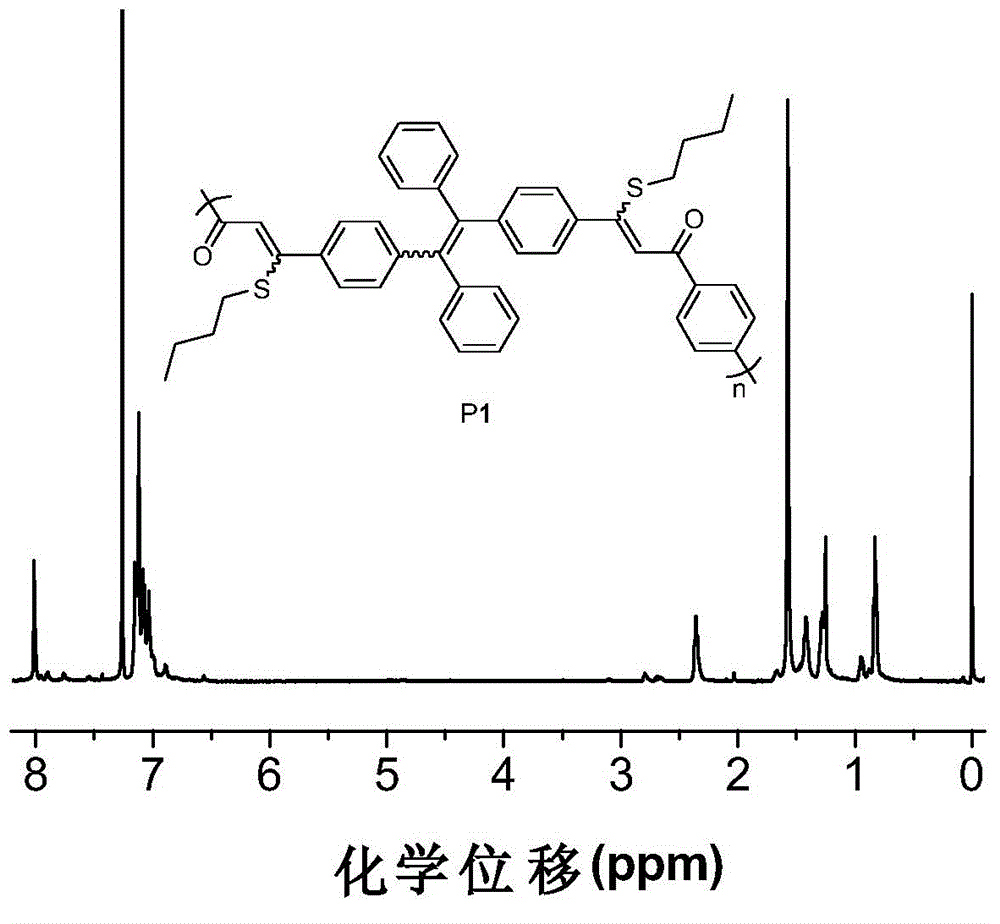

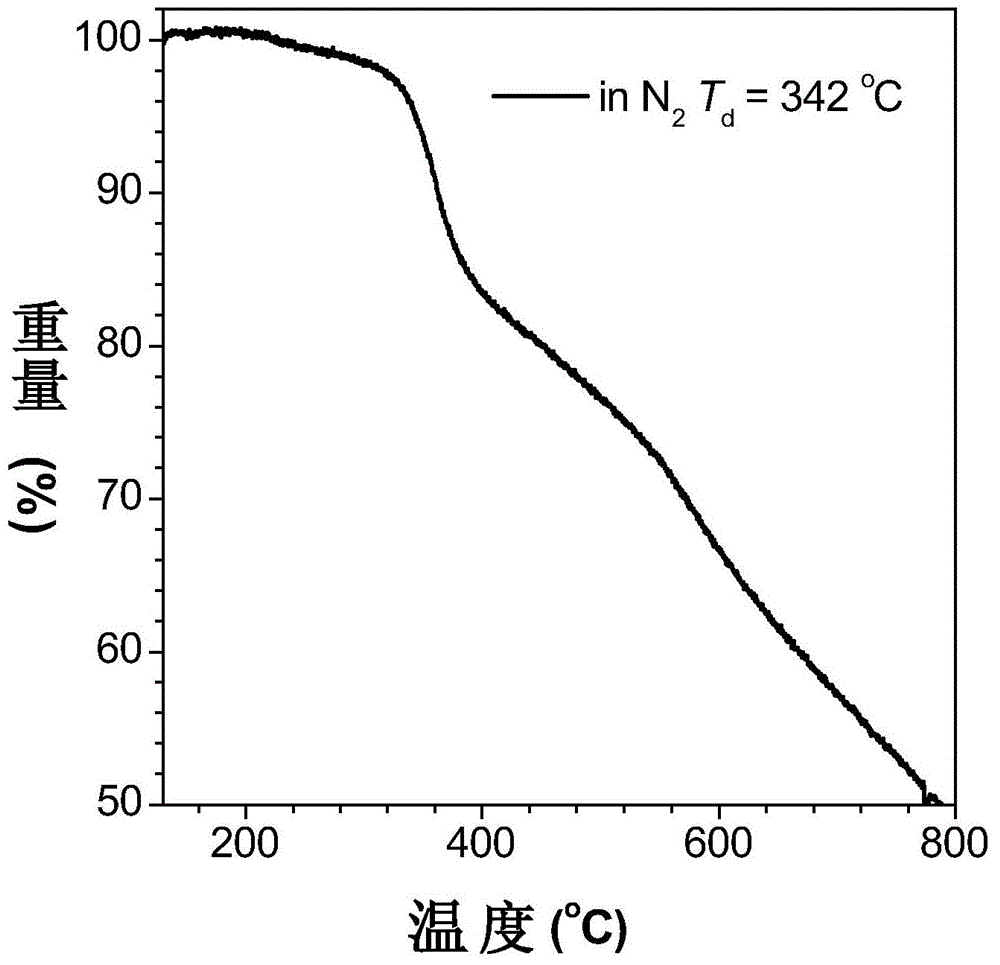

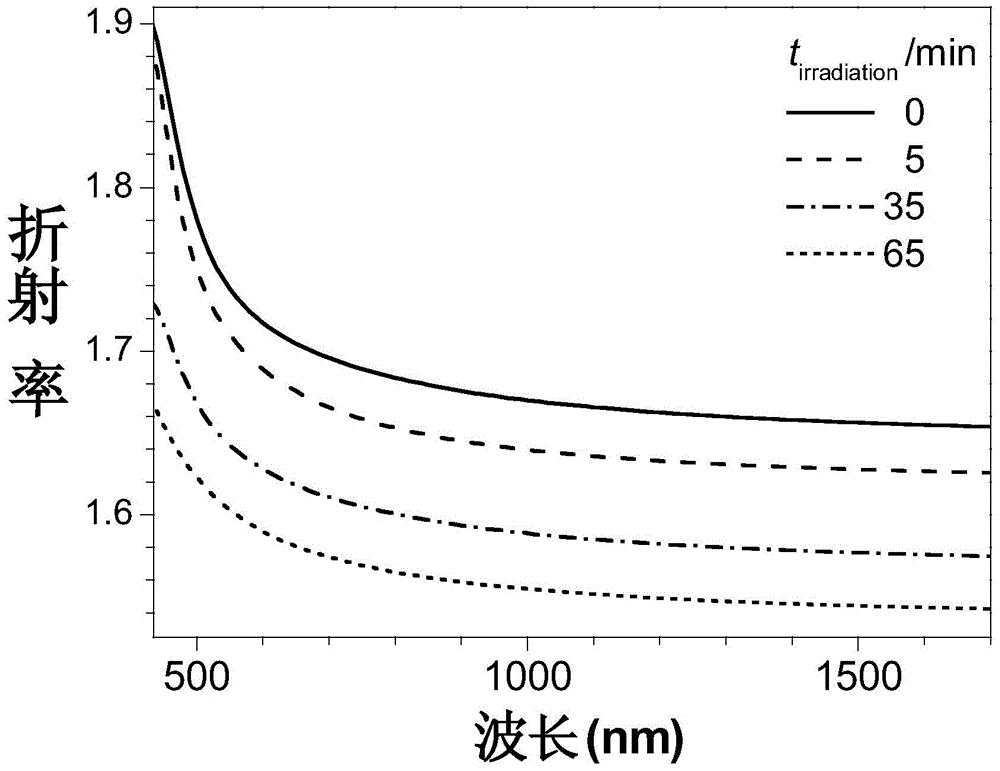

[0043] A conjugated high molecular polymer, its structural formula is as shown in P1:

[0044]

[0045] The conjugated high-molecular polymer is prepared by multi-component series polymerization reaction using acetylenic ketone oligomer as an intermediate, and the reaction equation is as formula (1):

[0046]

[0047] Wherein, the monomer M1 is diethynyltetraphenylethylene, which can be prepared according to the disclosed method of the document [Polym.Chem.2012,3,1481]; the monomer M2 is terephthaloyl chloride, which can be purchased from the market. In this example, it was purchased from Alfa Aesar Company; the monomer M3 is butanethiol, which can be purchased from the market, and in this example, it was purchased from TCI Company.

[0048] The specific preparation steps of the conjugated polymer are as follows:

[0049] (1) the catalytic amount of palladium catalyst Pd (PPh 3 ) 2 Cl 2 and CuI, and diethynyltetraphenylethylene and terephthaloyl chloride at a molar r...

Embodiment 2

[0060] A conjugated high molecular polymer, its structural formula is as shown in P2:

[0061]

[0062] The conjugated high-molecular polymer is prepared by taking acetylenic ketone oligomer as an intermediate through multi-component series polymerization reaction, and the reaction equation is as formula (2):

[0063]

[0064] Among them, the monomer M2 terephthaloyl chloride was purchased from Alfa Aesar Company; the monomer M4 diethynylbenzene was purchased from Anaiji Company; the monomer M5 o-phenylenediamine was purchased from Bailingwei Company.

[0065] The specific preparation steps of the conjugated polymer are as follows:

[0066] (1) the catalytic amount of palladium catalyst Pd (PPh 3 ) 2 Cl 2 and CuI, and diethynylbenzene and terephthaloyl chloride with a molar ratio of 1:1 were added to the polymerization tube, vacuumed and replaced with nitrogen for 3 times, and redistilled THF was injected into a syringe to dissolve, and then 1.05 equivalents of tris ...

Embodiment 3

[0070] A conjugated high molecular polymer, its structural formula is as shown in P3:

[0071]

[0072] The conjugated high-molecular polymer is prepared by taking acetylenic ketone oligomer as an intermediate through multi-component series polymerization reaction, and the reaction equation is as formula (3):

[0073]

[0074] Wherein, monomer M6 dibromoterephthaloyl chloride is prepared according to the disclosed method of document [Macromolecules 1992,25,7107]; Monomer sodium sulfide nonahydrate (Na 2 S·9H 2 O) purchased from Bailingwei Company.

[0075] The specific preparation steps of the conjugated polymer are as follows:

[0076] (1) the catalytic amount of palladium catalyst Pd (PPh 3 ) 2 Cl 2 and CuI, and diethynyltetraphenylethylene and 2,5-dibromoterephthaloyl chloride in a molar ratio of 1:1 were added to the polymerization tube, vacuumed and replaced with nitrogen for 3 times, and redistilled THF was injected with a syringe Dissolve, then add 1.05 equi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com