Polyimide with novel structure and preparation method of transparent polyimide film

A technology of polyimide and transparent film, which is applied in the field of preparation of polyimide and its transparent film, can solve problems such as inability to process and shape, and achieve the goal of improving transparency, good thermal performance and transparency, and large economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

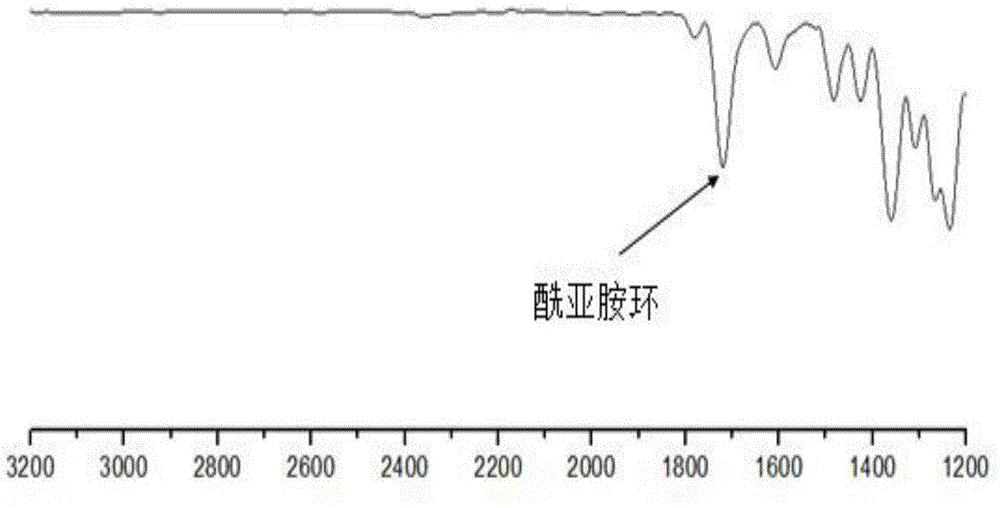

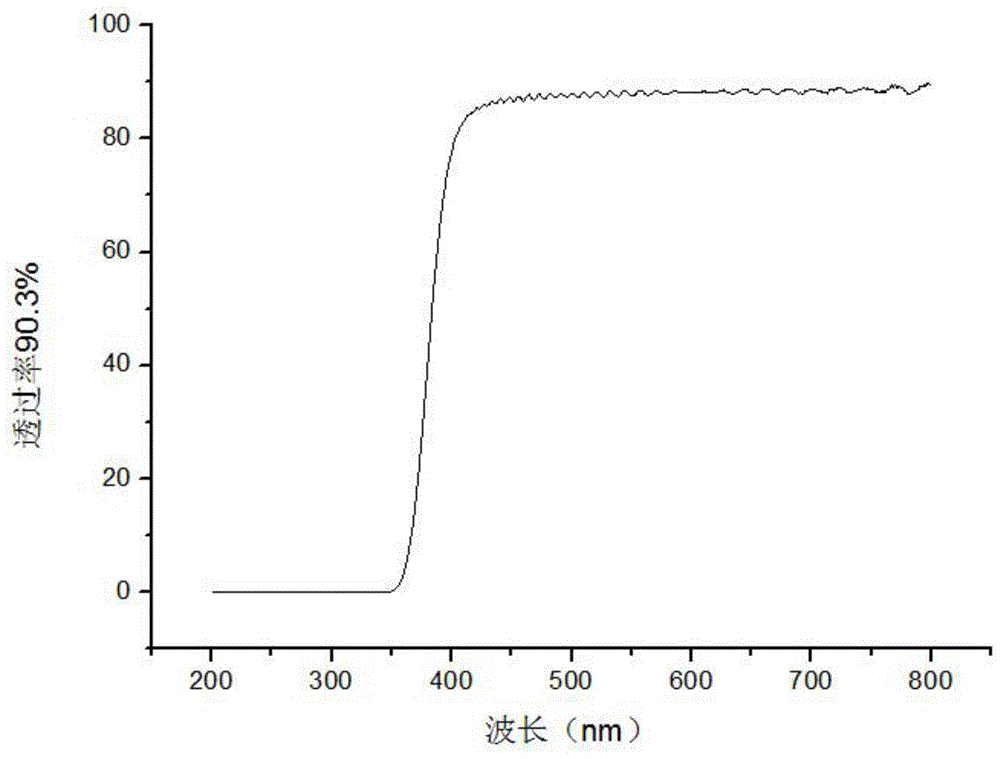

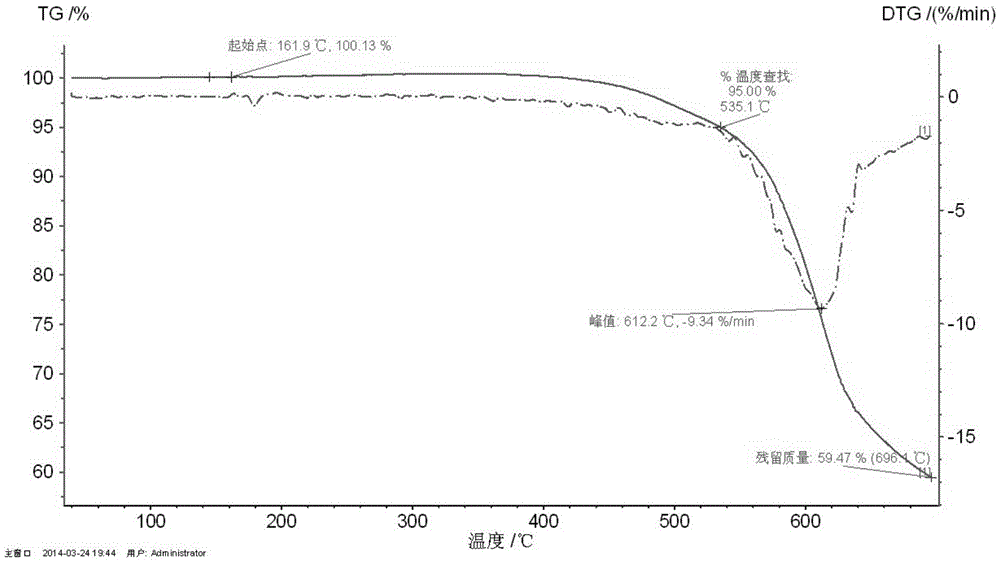

Method used

Image

Examples

Embodiment 1

[0030] Dissolve the mixed diamine of 1.162g (0.0043mol) 1,1-bis(4-aminophenyl)cyclohexane BAPC and 13.871g (0.0433mol) TFMB into 30g of strictly dry NMP at room temperature, nitrogen protection, Add 14.471g (0.0466mol) ODPA to it after mechanical stirring until completely dissolved, continue stirring for 1 hour under nitrogen protection, then add 0.496g (0.002mol) 4-PEPA to it, continue stirring for 24 hours under nitrogen protection to form a solid content of 50wt % polyamic acid solution with end-capping agent.

[0031] 4.15g of pyridine, 5.30g of triethylamine and 42.86g of acetic anhydride were added to the polyamic acid solution, stirred at room temperature for 24h, and the polyimide prepolymer solution was obtained after the reaction was completed, and the polyimide prepolymer The solution is precipitated into methanol, filtered, washed, and dried at 60°C to obtain a polyimide prepolymer solid, which is dissolved in NMP with the same mass as the polyimide prepolymer soli...

Embodiment 2

[0034] At room temperature, 6.614g (0.0247mol) of 1,1-bis(4-aminophenyl)cyclohexane BAPC and 7.898g (0.0247mol) of TFMB were dissolved in 20g of strictly dry NMP, under nitrogen protection, and mechanically stirred until After completely dissolving, add 14.992g (0.0484mol) ODPA thereinto, add 0.496g (0.002mol) 4-PEPA to it after continuing to stir 1h under nitrogen protection, continue to stir 24h under nitrogen protection to generate the belt with solid content of 60wt%. Polyamic acid solution of capping agent.

[0035]Add 4.298g (0.0544mol) of pyridine, 5.495g (0.0544mol) of triethylamine (0.0544mol) and 44.395g (0.4352mol) of acetic anhydride into the polyamic acid solution, stir at room temperature for 24h, and obtain the polyimide preform after the reaction is completed. Polymer solution, the polyimide prepolymer solution is precipitated into methanol, filtered, washed, and dried at 60°C to obtain a polyimide prepolymer solid, which is dissolved in a polyimide prepolymer ...

Embodiment 3

[0038] At room temperature, 2.143g (0.0080mol) of 1,1-bis(4-aminophenyl)cyclohexane BAPC and 12.796g (0.0400mol) of TFMB were dissolved in 45g of strictly dried NMP, under nitrogen protection, and mechanically stirred until After completely dissolving, add 14.565g (0.0470mol) ODPA thereinto, continue to stir 1h under nitrogen protection, add 0.496g (0.002mol) 4-PEPA to it after 1h, continue to stir 24h under nitrogen protection to generate solid content and be 40wt% ribbon Polyamic acid solution of capping agent.

[0039] Add 7.423g (0.094mol) of pyridine, 1.186g (0.0117mol) of triethylamine and 43.131g (0.4229mol) of acetic anhydride to the polyamic acid solution, stir at room temperature for 24h, and obtain the polyimide preform after the reaction. Polymer solution, the polyimide prepolymer solution is precipitated into methanol, filtered, washed, and dried at 60°C to obtain a polyimide prepolymer solid, which is dissolved in a polyimide prepolymer The polyimide prepolymer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com