Rare earth hydrotalcite composite heat stabilizer for PVC and preparation method thereof

A composite heat stabilizer and hydrotalcite technology, applied in the field of polyvinyl chloride molding and processing, can solve the problems of short static thermal stability time, poor performance, only applicable, etc., achieve moderate torque, short plasticizing time, and improve processing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

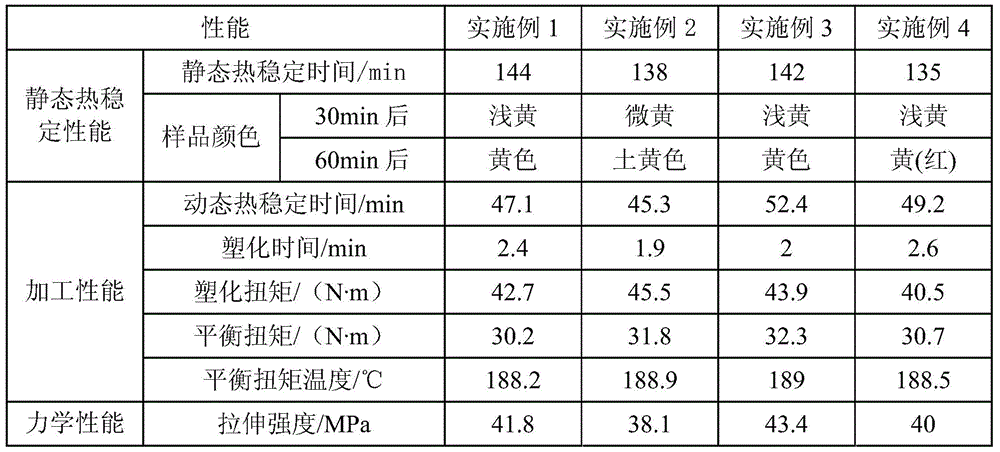

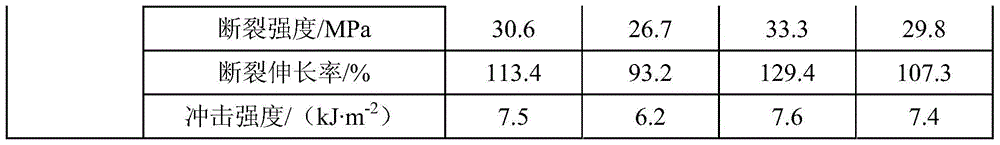

Examples

preparation example Construction

[0028] The preparation method of the rare earth hydrotalcite composite heat stabilizer for PVC according to the second aspect of the present invention is used to prepare the rare earth hydrotalcite composite heat stabilizer for PVC according to the first aspect of the present invention, including the steps: (1) Divalent metal salt, trivalent metal salt and rare earth salt are soluble in CO removal 2 Of deionized water to obtain the first solution, where n(M 2+ ) / [n(M 3+ )+n(RE 3+ )]=2~3, n(RE 3+ ) / n(M 3+ )=0.02~0.12, n is the amount of substance, M 2+ Cation of divalent metal, M 3+ It is the cation of trivalent metal; (2) Sodium hydroxide and surfactant are dissolved in CO removal 2 Of deionized water to obtain a second solution, where n(NaOH) / [n(M 2+ )+n(M 3+ )+n(RE 3+ )]=2, n(surfactant) / [n(M 3+ )+n(RE 3+ )]=2; (3) in N 2 Under protection, drop the first solution and the second solution into 30ml-50mL deionized water, the reaction temperature is 85℃, stir to keep the pH of the r...

Embodiment 1

[0038] Weigh 23.1g Mg(NO 3 ) 2 ·6H 2 O, 10.7gAl(NO 3 ) 3 ·9H 2 O and 0.5g LaCl 3 ·6H 2 O soluble in CO removal 2 To obtain the first solution in the deionized water;

[0039] Weigh 9.6g NaOH and 17.3g sodium lauryl sulfate (C 12 H 25 SO 4 Na) soluble in CO removal 2 Of deionized water to obtain a second solution;

[0040] In N 2 Under protection, slowly drop the first solution and the second solution into a three-necked flask pre-filled with 50 mL of deionized water. The reaction temperature is 85°C, with vigorous stirring, and the pH of the reaction solution is maintained at 11-13. After the addition is complete, Reflux at 85°C for 4 hours, then age the reaction solution at 110°C for 8 hours, filter, wash, dry, and grind to obtain sodium lauryl sulfate pillared magnesium aluminum lanthanum hydrotalcite;

[0041] In parts by mass, take 30 parts of sodium lauryl sulfate pillared magnesium aluminum lanthanum hydrotalcite, 35 parts of pentaerythritol and 20 parts of β-diketone, mix and ...

Embodiment 2

[0043] Weigh 5.5g ZnCl 2 , 6.7gAl(NO 3 ) 3 ·9H 2 O and 0.8g Ce(NO 3 ) 3 ·6H 2 O soluble in CO removal 2 To obtain the first solution in the deionized water;

[0044] Weigh 4.8g NaOH and 10.9g sodium dodecyl sulfonate (C 12 H 25 SO 3 Na) soluble in CO removal 2 Of deionized water to obtain a second solution;

[0045] In N 2 Under protection, slowly drop the first solution and the second solution into a three-necked flask pre-filled with 40 mL of deionized water. The reaction temperature is 85°C, and the reaction temperature is vigorously stirred to maintain the pH of the reaction solution at 11-13. After the addition is complete, Reflux at 85°C for 6 hours, then age the reaction solution at 110°C for 12 hours, filter, wash, dry, and grind to obtain dodecyl sulfonic acid pillared zinc aluminum cerium hydrotalcite;

[0046] In parts by mass, take 45 parts of dodecyl sulfonic acid pillared zinc-aluminum-cerium hydrotalcite, 50 parts of pentaerythritol and 40 parts of β-diketone, mix and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com