Termite-resistant adhesive used for polyethylene pipeline, adhesive tape and preparation of adhesive tape

An anti-termite agent and polyethylene technology, which is applied in the direction of adhesives, hydrocarbon copolymer adhesives, film/sheet adhesives, etc., can solve the difficulty of processing the anti-termite agent, the easy decomposition of the anti-termit Prevent and control the problems of short time limit and other problems, achieve long-term sealing protection performance, not easy to degrade, and ensure the effect of long-term termite control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The components of the anti-termite adhesive are as follows: thermoplastic elastomer (SIS) 10%; amorphous α-olefin copolymer (2780A) 15%; medium molecular weight polyisobutylene (8550) 25%; terpene resin 15% ; Inorganic reinforcing powder (kaolin) 30%; antioxidant (1010) 2%; black masterbatch 1%; deltamethrin 2%.

[0052] The base material of the tape is: polyethylene base material containing anti-termite agent, the thickness is 0.3~0.4mm

[0053] The adhesive tape is prepared according to the following steps:

[0054] 1) Weigh the raw materials according to the mass ratio according to the above formula, add them into the kneader 1, and mix them to make an adhesive;

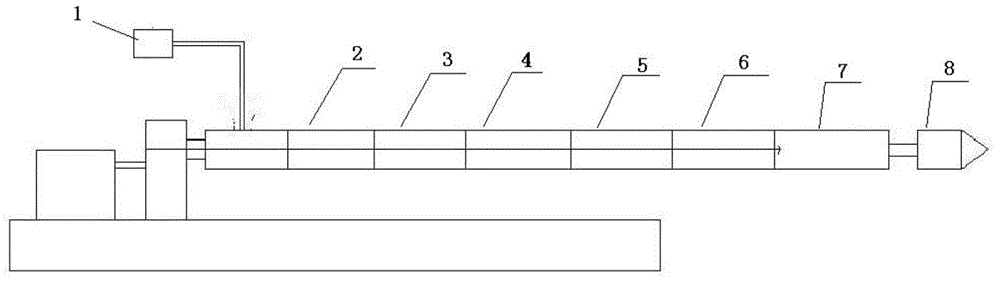

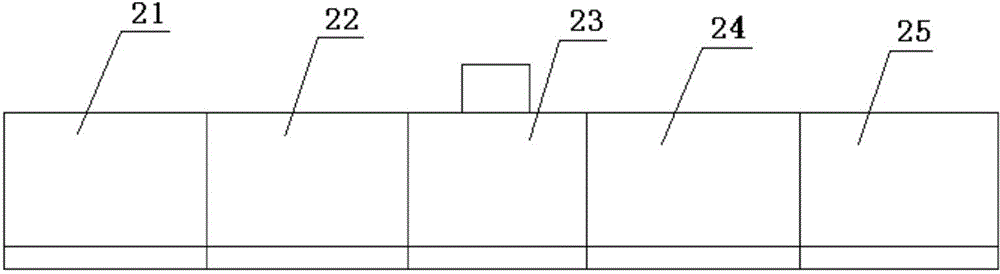

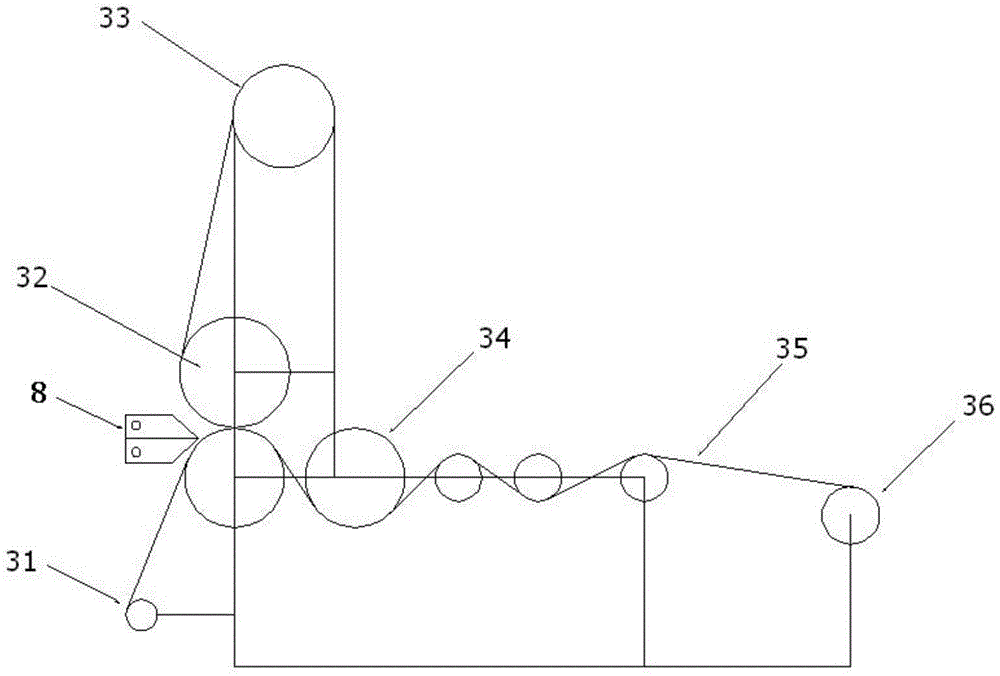

[0055] 2) if figure 1 As shown, the adhesive mixed in the kneader 1 is transported to the discharge port of the extruder through the gear pump, and passes through the first barrel zone 2, the second barrel zone 3, the third barrel zone 4, and the fourth barrel zone 5. After the fifth zone 6 of the barrel...

Embodiment 2

[0058] The components of the anti-termite adhesive are: thermoplastic elastomer (SIS) 6%; amorphous α-olefin copolymer (LBR-1186) 25%; medium molecular weight polyisobutylene (B15) 15%; terpene resin 10%; Inorganic reinforcement powder (BaSO 4 ) 40%; antioxidant (1010) 1%; black mother 1%; fenvalerate 2%.

[0059] The base material of the tape is: a polyethylene base material containing an anti-termite agent, and the composition of the base material of the tape is: ultra-low density polyethylene (DFDA-1095NT) 70%; maleic anhydride modified linear low density Polyethylene (208) 10%; medium density polyethylene (3321C) 8.0%; high density polyethylene (5300B) 7.0%; primary antioxidant 10101.0%; secondary antioxidant DSTDP 1.0%; black masterbatch 1.0%; biphenyl 1.0% permethrin, 1.0% permethrin, and the thickness of the adhesive tape substrate is 0.3-0.4mm.

[0060] The preparation steps and process of the tape are the same as in Example 1, and the thickness of the prepared anti-...

Embodiment 3

[0062] The components of the anti-termite adhesive are: thermoplastic elastomer (SBS) 5%; amorphous α-olefin copolymer (2180) 18%; medium molecular weight polyisobutylene (B12) 16%; rosin resin 12%; Inorganic reinforcing powder (talc powder) 45%; antioxidant (1010) 1%; black masterbatch 2%; anti-termite agent 1%.

[0063] The substrate is a polyethylene film with a thickness of 0.3-0.4mm.

[0064] The preparation steps and process of the tape are the same as in Example 1, and the thickness of the prepared anti-termite tape is 1.0mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com