Calcium naphthenate zirconium-based hexurea lubricating grease and preparation method thereof

A technology based on hexapolyurea lubricating grease and calcium naphthenate, which is applied in the field of lubricating grease, can solve problems such as the high price of calcium sulfonate with high alkali value, not being rapidly promoted, and complicated preparation process, and achieve low cost and high product quality. The effect of stability and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

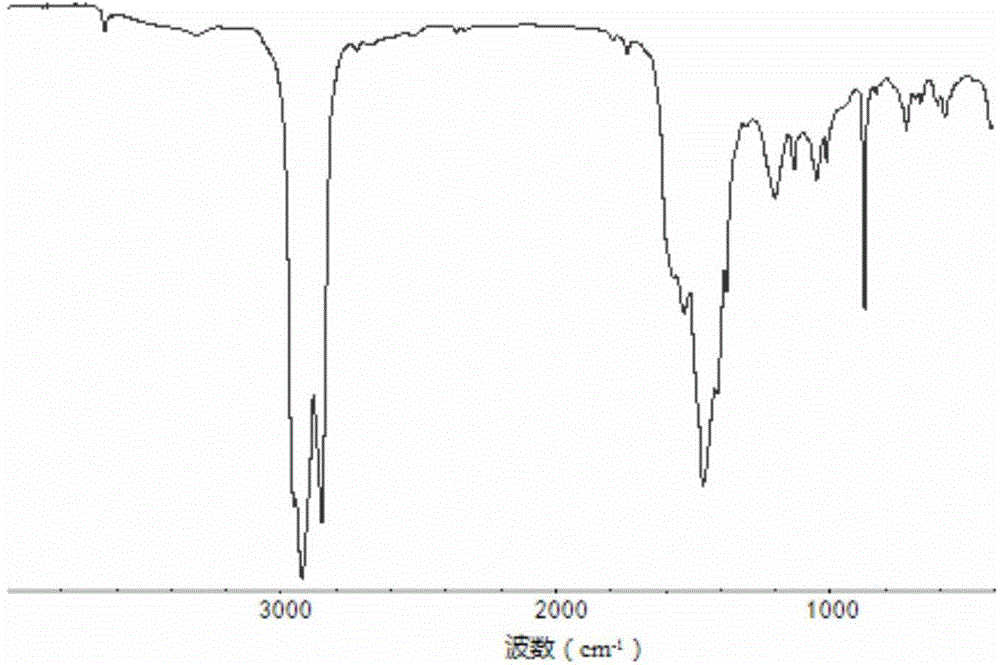

Image

Examples

preparation example Construction

[0021] The present invention also provides a preparation method of the above lubricating grease.

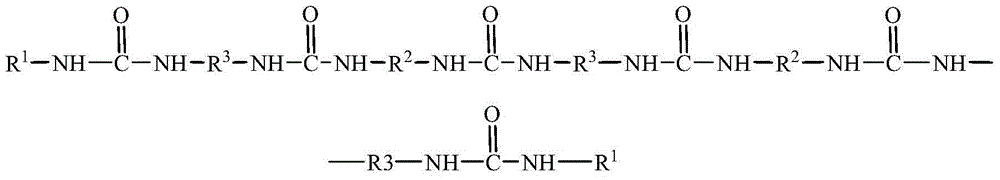

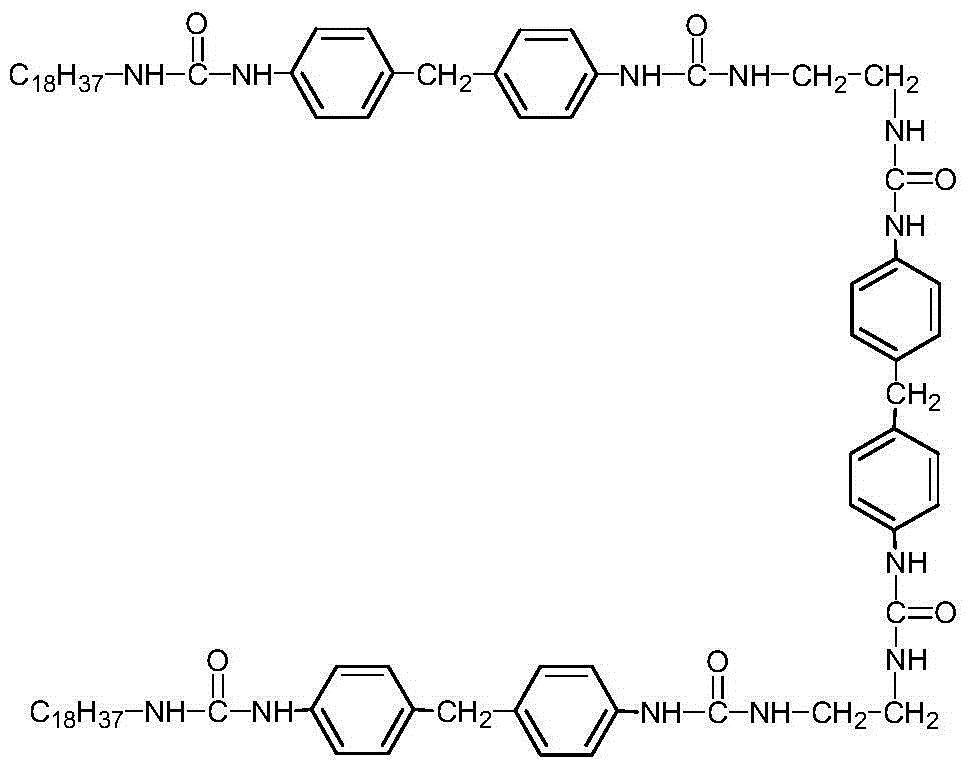

[0022] In one aspect, the present invention provides a calcium naphthenate-zirconium-based hexapolyurea grease, which comprises the following components based on the weight of the grease: 10-70% by weight of non-Newtonian calcium naphthenate; 1-10 % by weight of zirconium salts of higher fatty acids; 1-15% by weight of zirconium salts of small molecular inorganic acids and / or lower fatty acids; 0.5-30% by weight of polyurea compounds; 10-80% by weight of base oils, wherein, high-grade The zirconium salt of fatty acid is formed by the reaction of higher fatty acid and component A, the zirconium salt of small molecule inorganic acid and / or lower fatty acid is formed by the reaction of small molecule inorganic acid and / or lower fatty acid with component A, component A is at least one of zirconium oxide, zirconium hydroxide, and zirconium alkoxide, and the polyurea compound is a hexa...

Embodiment 1

[0075] This example is used to illustrate the calcium naphthenate-zirconium-based hexaurea grease prepared in the present invention.

[0076] Raw material components: ultra-high base value calcium naphthenate (total base value 400mgKOH / g, 30kg); HVI150BS lubricating base oil (100°C kinematic viscosity is 31mm 2 / s, 30kg); naphthenic acid (total acid value 180mgKOH / g, 2.8kg); acetic acid (0.56kg); Zr(OH) 4 (3.9kg); 12-hydroxystearic acid (2kg); boric acid (2.32kg); octadecylamine (0.84kg); ethylenediamine (0.19kg); MDI (1.17kg); HVI500SN lubricating base oil (100℃ Kinematic viscosity is 11mm 2 / s, 18kg).

[0077] Add 30kg of ultra-high alkalinity calcium naphthenate with a total base value of 400mgKOH / g and 30kg of HVI150BS lubricating base oil into a normal-pressure reactor with a volume of 160L and heating, stirring, circulation, and cooling, stir and heat Raise the temperature to 50°C and keep the temperature constant for 30 minutes; add 2.8kg of naphthenic acid, control ...

Embodiment 2

[0080] This example is used to illustrate the calcium naphthenate-zirconium-based hexaurea grease prepared in the present invention.

[0081] Raw material components: ultra-high base value calcium naphthenate (total base value 400mgKOH / g, 30kg); HVI150BS lubricating base oil (100°C kinematic viscosity is 31mm 2 / s, 30kg); naphthenic acid (total acid value 180mgKOH / g, 2.8kg); acetic acid (0.56kg); Zr(OH) 4 (3.9kg); 12-hydroxystearic acid (2kg); boric acid (2.32kg); octadecylamine (0.84kg); ethylenediamine (0.19kg); MDI (1.17kg); HVI500SN lubricating base oil (100℃ Kinematic viscosity is 11mm 2 / s, 18kg).

[0082] Add 30kg of ultra-high alkalinity calcium naphthenate with a total base value of 400mgKOH / g and 30kg of HVI150BS lubricating base oil into a normal-pressure reactor with a volume of 160L and heating, stirring, circulation, and cooling, stir and heat Raise the temperature to 50°C and keep the temperature constant for 30 minutes; add 2.8kg of naphthenic acid, control ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total base number | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap