BaFe12O19/CoFe2O4 layered permanent magnetic composite material and preparation method thereof

A technology of bafe12o19 and composite materials, which is applied in the field of material science, can solve problems affecting magnetic properties and exchange coupling effects, and achieve the effects of easy large-scale production, suppression of mutual reactions, and simple processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

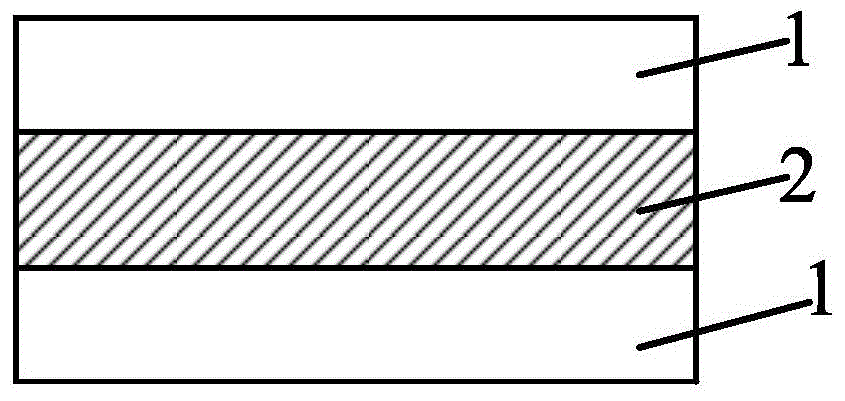

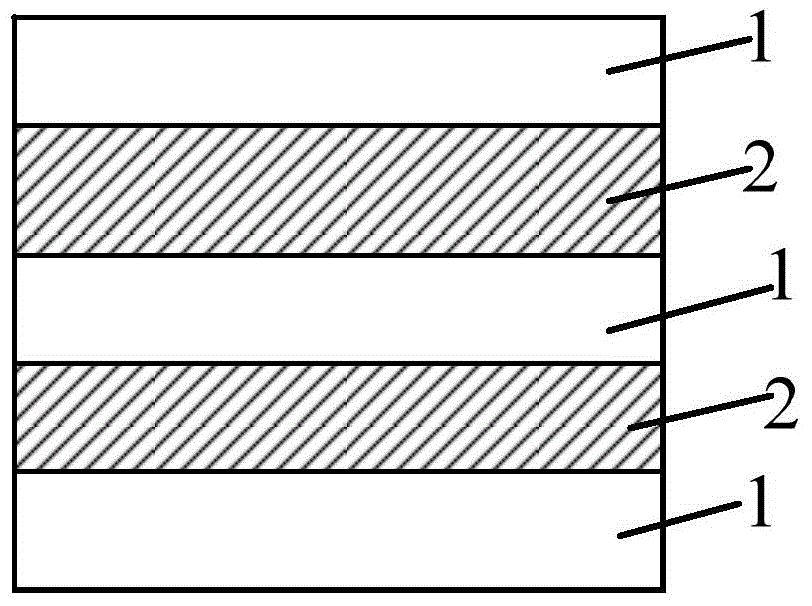

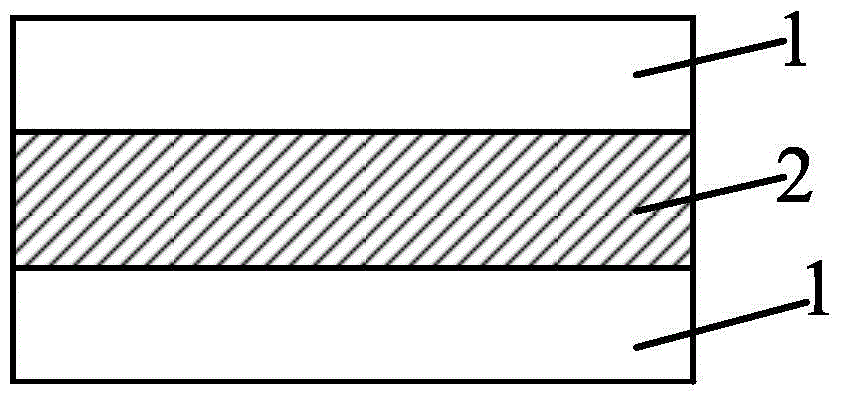

Image

Examples

Embodiment 1

[0036] a BaFe 12 o 19 / CoFe 2 o 4 The chemical expression of the layered permanent magnet composite is (1-x)BaFe 12 o 19 / xCoFe 2 o 4 , where x is CoFe 2 o 4 The mass percentage of x=11.1%.

[0037] The above BaFe 12 o 19 / CoFe 2 o 4 The preparation method of layered permanent magnetic composite material comprises the following steps:

[0038] 1) According to the general chemical formula BaFe 12 o 19 will analyze pure BaCO 3 , Fe 2 o 3 After preparation (that is, mixing), wet ball mill for 4 hours, then dry, sieve, briquette, and pre-burn at 1150 ° C for 6 hours, then crush the resulting block sample and pass through a 120-mesh sieve to obtain BaFe 12 o 19 Powder.

[0039] 2) to BaFe 12 o 19 The powder is granulated after adding a 10% polyvinyl alcohol aqueous solution, and then sieved through a 60-mesh sieve to obtain BaFe 12 o 19 powder; wherein, the mass of polyvinyl alcohol aqueous solution is BaFe 12 o 19 12% of powder mass;

[0040] 3) Accordin...

Embodiment 2

[0048] a BaFe 12 o 19 / CoFe 2 o 4 The chemical expression of the layered permanent magnet composite is (1-x)BaFe 12 o 19 / xCoFe 2 o 4 , where x is CoFe 2 o 4 The mass percentage of x=22.2%.

[0049] The above BaFe 12 o 19 / CoFe 2 o 4 The preparation method of layered permanent magnetic composite material comprises the following steps:

[0050] 1) According to the general chemical formula BaFe12 o 19 will analyze pure BaCO 3 , Fe 2 o 3 After preparation (that is, mixing), wet ball mill for 4 hours, then dry, sieve, briquette, and pre-burn at 1200 ° C for 4 hours, then crush the resulting block sample and pass through a 120-mesh sieve to obtain BaFe 12 o 19 Powder.

[0051] 2) to BaFe 12 o 19 The powder is granulated after adding a 10% polyvinyl alcohol aqueous solution, and then sieved through a 60-mesh sieve to obtain BaFe 12 o 19 powder; wherein, the mass of polyvinyl alcohol aqueous solution is BaFe 12 o 19 10% of powder mass;

[0052] 3) According ...

Embodiment 3

[0060] a BaFe 12 o 19 / CoFe 2 o 4 The chemical expression of the layered permanent magnet composite is (1-x)BaFe 12 o 19 / xCoFe 2 o 4 , where x is CoFe 2 o 4 The mass percentage of x=33.3%.

[0061] The above BaFe 12 o 19 / CoFe 2 o 4 The preparation method of layered permanent magnetic composite material comprises the following steps:

[0062] 1) According to the general chemical formula BaFe 12 o 19 will analyze pure BaCO 3 , Fe 2 o 3 After preparation (that is, mixing), wet ball mill for 4 hours, then dry, sieve, briquette, and pre-burn at 1170 ° C for 5 hours, then crush the resulting block sample and pass through a 120-mesh sieve to obtain BaFe 12 o 19 Powder.

[0063] 2) to BaFe 12 o 19 The powder is granulated after adding a 10% polyvinyl alcohol aqueous solution, and then sieved through a 60-mesh sieve to obtain BaFe 12 o 19 powder; wherein, the mass of polyvinyl alcohol aqueous solution is BaFe 12 o 19 8% of powder mass;

[0064] 3) According...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

| Remanent polarization | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com