Special controlled-release water soluble fertilizer for grapes and preparation method thereof

A water-soluble fertilizer and grape technology, applied in the application, nitrogen fertilizer, potassium fertilizer and other directions, can solve the problems of easy fixation or loss of phosphorus and potassium elements, and achieve the effect of improving nutrient utilization rate, large market value and good water solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

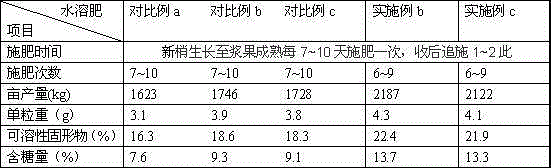

Examples

Embodiment 1

[0042] 1) Make 3 parts of polyformamidosuccinic acid inorganic silica gel fine particles and 40 parts of water to make a gel solution for use; first put 90 parts of potassium dihydrogen phosphate and 100 parts of potassium sulfate into the dispersion mixer, and then add the prepared The gel solution was stirred, mixed and dispersed for 20 minutes, and dried to obtain gelled potassium dihydrogen phosphate and potassium sulfate powder;

[0043] 2) Add 110 parts of NTA chelated calcium, 150 parts of NTA chelated magnesium, 70 parts of glycine chelated iron, 20 parts of EDTA chelated manganese and 15 parts of EDTA chelated zinc into a high-speed mixer and mix at high speed for 20 minutes to obtain chelated A mixture of medium and trace elements;

[0044] 3) Combine 190 parts of ammonium nitrate, 40 parts of ammonium dihydrogen phosphate, 30 parts of heavy superphosphate, 230 parts of potassium nitrate, 7 parts of borax and the gelled potassium dihydrogen phosphate and potassium su...

Embodiment 2

[0046] 1) Make 4 parts of polyformamidosuccinic acid diatomite fine particles and 40 parts of water into a gel solution for use; first put 100 parts of potassium dihydrogen phosphate and 110 parts of potassium sulfate into the dispersion mixer, and then add the preparation A good gel solution was stirred, mixed and dispersed for 30 minutes, and dried to obtain gelled potassium dihydrogen phosphate and potassium sulfate powder;

[0047] 2) Add 120 parts of NTA chelated calcium, 150 parts of NTA chelated magnesium, 70 parts of glycine chelated iron, 20 parts of EDTA chelated manganese and 16 parts of EDTA chelated zinc into a high-speed mixer and mix at high speed for 25 minutes to obtain chelated A mixture of medium and trace elements;

[0048] 3) Combine 200 parts of ammonium nitrate, 50 parts of ammonium dihydrogen phosphate, 30 parts of heavy superphosphate, 240 parts of potassium nitrate, 8 parts of borax and the gelled potassium dihydrogen phosphate and potassium sulfate o...

Embodiment 3

[0050] 1) Mix 4 parts of polycarbonyl diamide glutaric acid zeolite fine particles and 50 parts of water to make a gel solution for use; first put 100 parts of potassium dihydrogen phosphate and 110 parts of potassium sulfate into the dispersion mixer, and then add the preparation A good gel solution was stirred, mixed and dispersed for 30 minutes, and dried to obtain gelled potassium dihydrogen phosphate and potassium sulfate powder;

[0051] 2) Add 120 parts of NTA chelated calcium, 160 parts of NTA chelated magnesium, 80 parts of glycine chelated iron, 25 parts of EDTA chelated manganese and 17 parts of EDTA chelated zinc into a high-speed mixer and mix at high speed for 20 minutes to obtain chelated A mixture of medium and trace elements;

[0052] 3) Combine 210 parts of ammonium nitrate, 50 parts of ammonium dihydrogen phosphate, 40 parts of heavy superphosphate, 240 parts of potassium nitrate, 8 parts of borax and the gelled potassium dihydrogen phosphate and potassium s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com