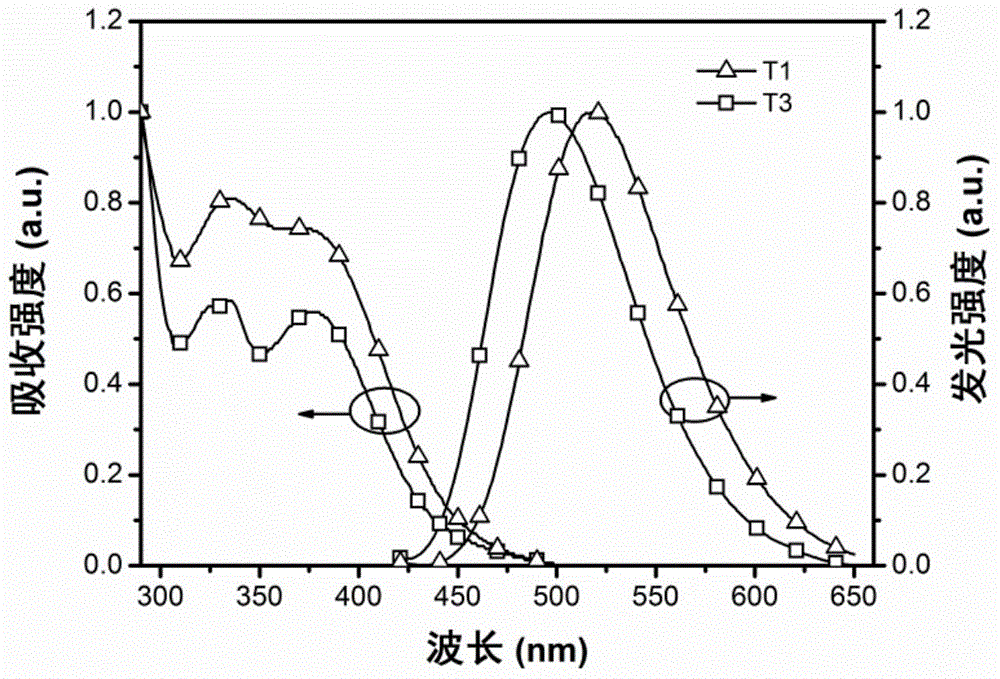

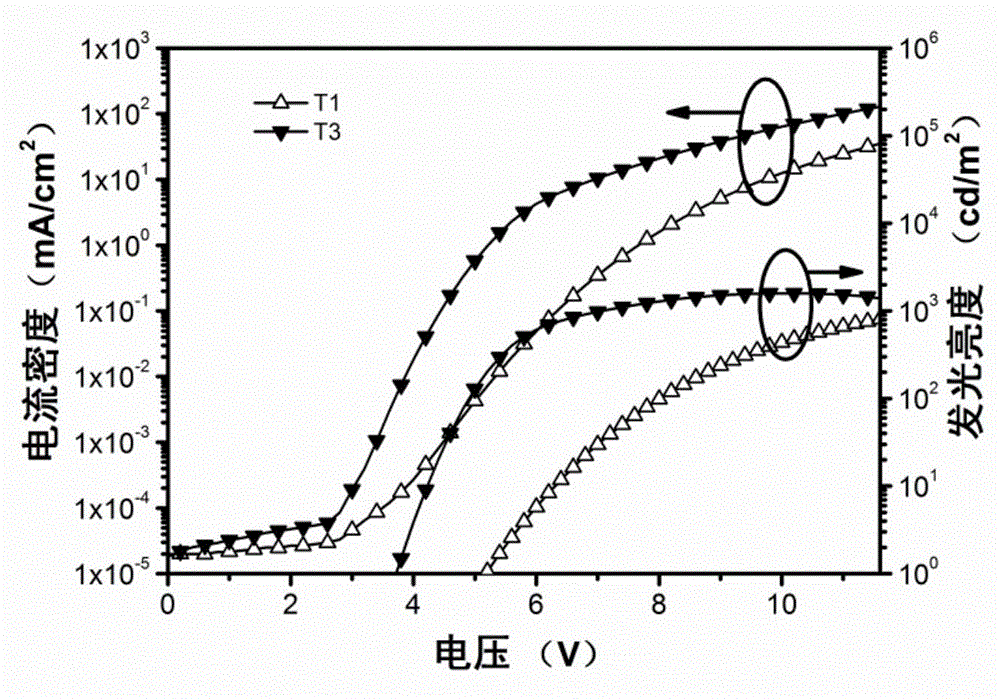

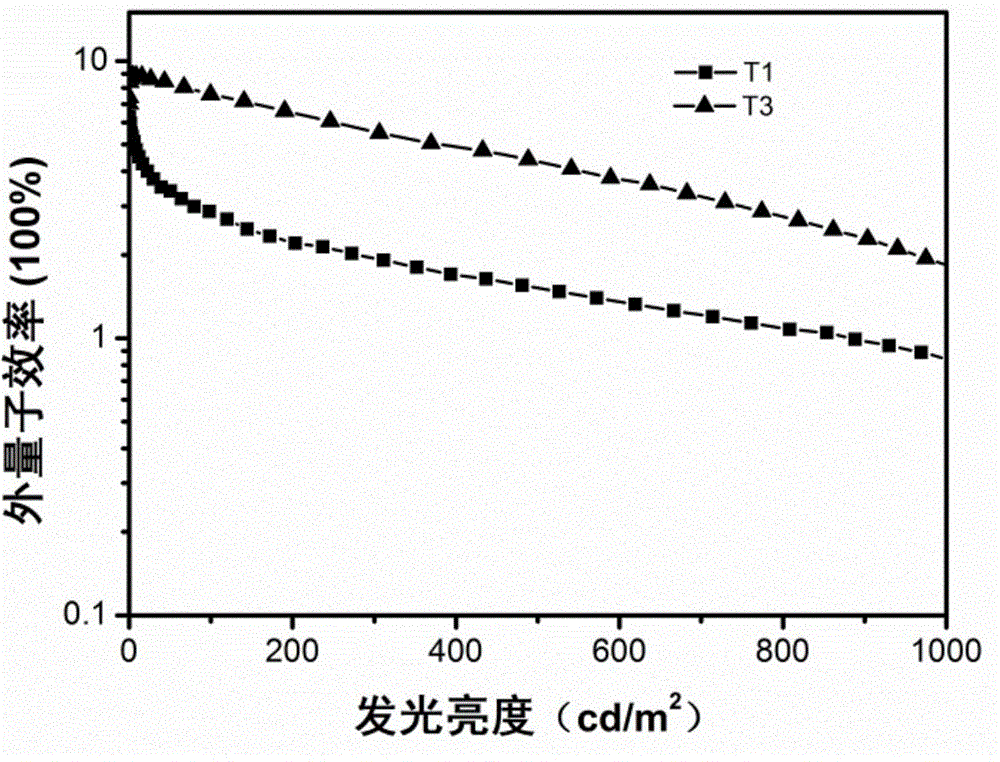

Thianthrene oxide-aromatic amine organic luminescent small molecule as well as preparation and application thereof

A technology of thianthrene oxide and aromatic amine is applied in the field of organic light-emitting materials to achieve the effects of simple material structure, delayed fluorescence characteristics and molecular weight determination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In this example, the preparation of thianthrene oxide-aromatic amine organic light-emitting small molecule T1, the specific synthesis route is as follows:

[0036]

[0037] Concrete preparation process is as follows:

[0038] (1) Preparation of intermediate 2-bromothianthrene (S1): The raw material thianthrene (6.5 g, 30 mmol) was put into a 250 ml three-necked reaction flask, and 60 ml of glacial acetic acid was added to dissolve it. Under the protection of argon, slowly add 1.2eq of liquid bromine (5.76g, 36mmol) dropwise. After the dropwise addition, heat to 80°C. After reacting for 5h, add 100ml of sodium bisulfite solution (1.58M) to quench the reaction , after extracting with dichloromethane, washed 3 times with saturated sodium chloride solution, added anhydrous magnesium sulfate to dry, and spin-dried with a rotary evaporator; the resulting solid was recrystallized with n-hexane to obtain 7.35 g of a white solid, the yield 83.5%. 1HNMR (600MHz, CDCl 3 , δ,...

Embodiment 2

[0042] In this example, the preparation of thianthrene oxide-aromatic amine organic light-emitting small molecule T2, the specific synthesis route is as follows:

[0043]

[0044] Concrete preparation process is as follows:

[0045](1) Preparation of intermediate 2,3,6,7-tetrabromothianthrene (S3): Put the raw material thianthrene (4.32g, 20mmol) into a 250ml three-necked reaction flask, and add 50ml of glacial acetic acid to dissolve it , under the protection of argon, slowly drop 8eq of liquid bromine (25.6g, 160mmol), after the dropwise addition, heat to 80°C, after reacting for 5h, add 150ml of sodium bisulfite solution (2M) to quench the reaction; After extracting with dichloromethane, wash 3 times with saturated sodium chloride solution, add anhydrous magnesium sulfate to dry, and spin dry with a rotary evaporator; the obtained solid is recrystallized with n-hexane to obtain 10 g of a white solid with a yield of 84%. . 1HNMR (600MHz, CDCl 3 , δ, ppm) 7.63 (s, 4H); ...

Embodiment 3

[0049] In this example, the preparation of thianthrene oxide-aromatic amine organic light-emitting small molecule T3, the specific synthesis route is as follows:

[0050]

[0051] Concrete preparation process is as follows:

[0052] (1) Prepare intermediate 2-bromothianthrene (S1) according to step (1) in Example 1;

[0053] (2) Preparation of intermediate 2-carbazolethianthrene (S5): under argon protection, intermediate S1 (2g, 6.78mmol), carbazole (1.2g, 7.14mmol), anhydrous potassium carbonate (3.3 g, 23.8mmol) and cuprous iodide (3.3g, 17mmol) into a 100ml three-necked flask, add 25ml1,3-dimethylpropylene urea (DMPU) to dissolve them, then add phase catalyst 18 crown 6 (300mg) , stirred at room temperature for 20 minutes, then heated to 180 ° C, and reacted for 24 hours; after the reaction, the inorganic salt was removed by suction filtration, then extracted with dichloromethane, washed 3 times with saturated sodium chloride solution, dried by adding anhydrous magnesiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Emission peak | aaaaa | aaaaa |

| Emission peak | aaaaa | aaaaa |

| Maximum current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com