Bismuth nickelate nano-wire multifunctional paint

A technology of bismuth nickelate and nanowires, applied in the field of coatings, can solve problems such as single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

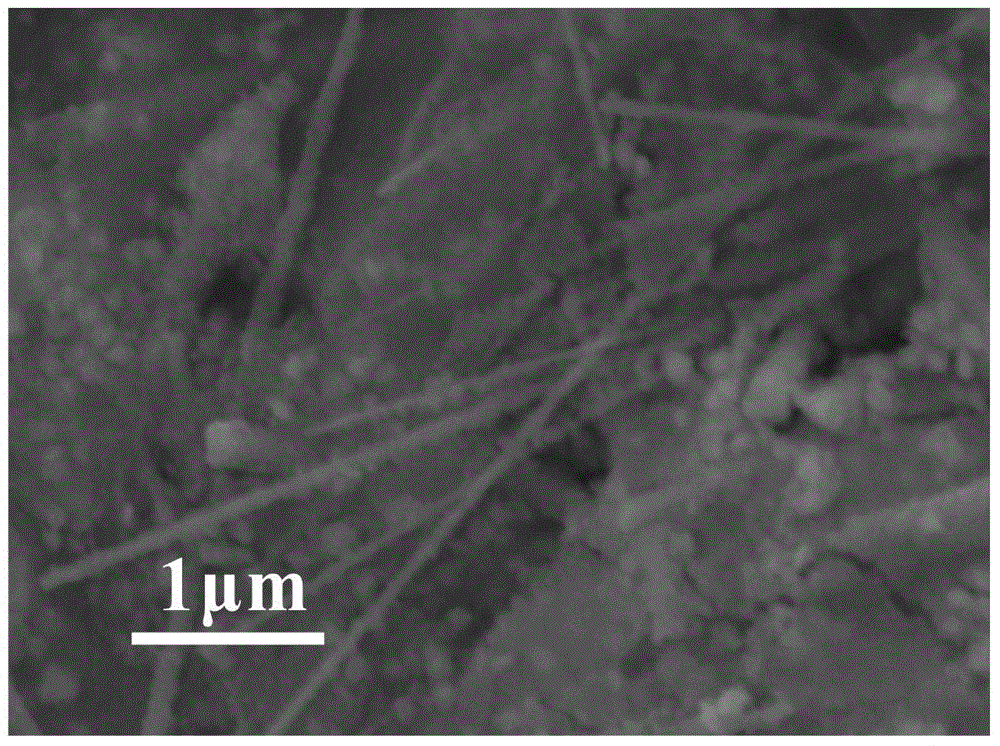

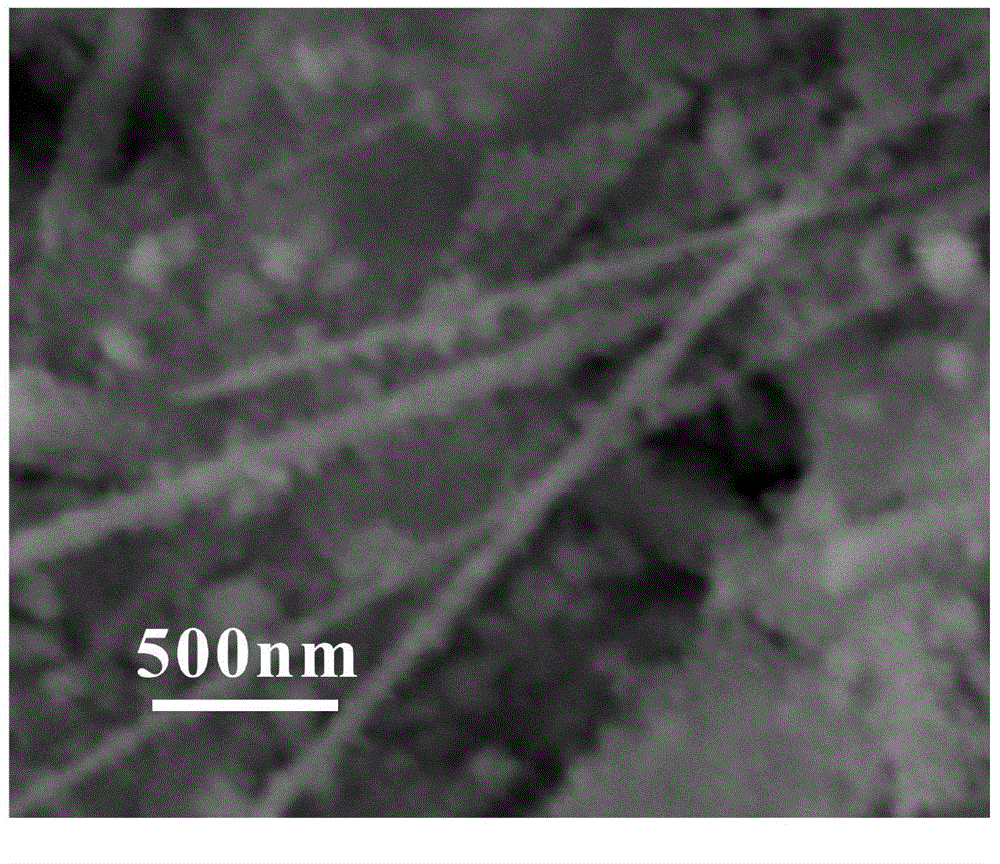

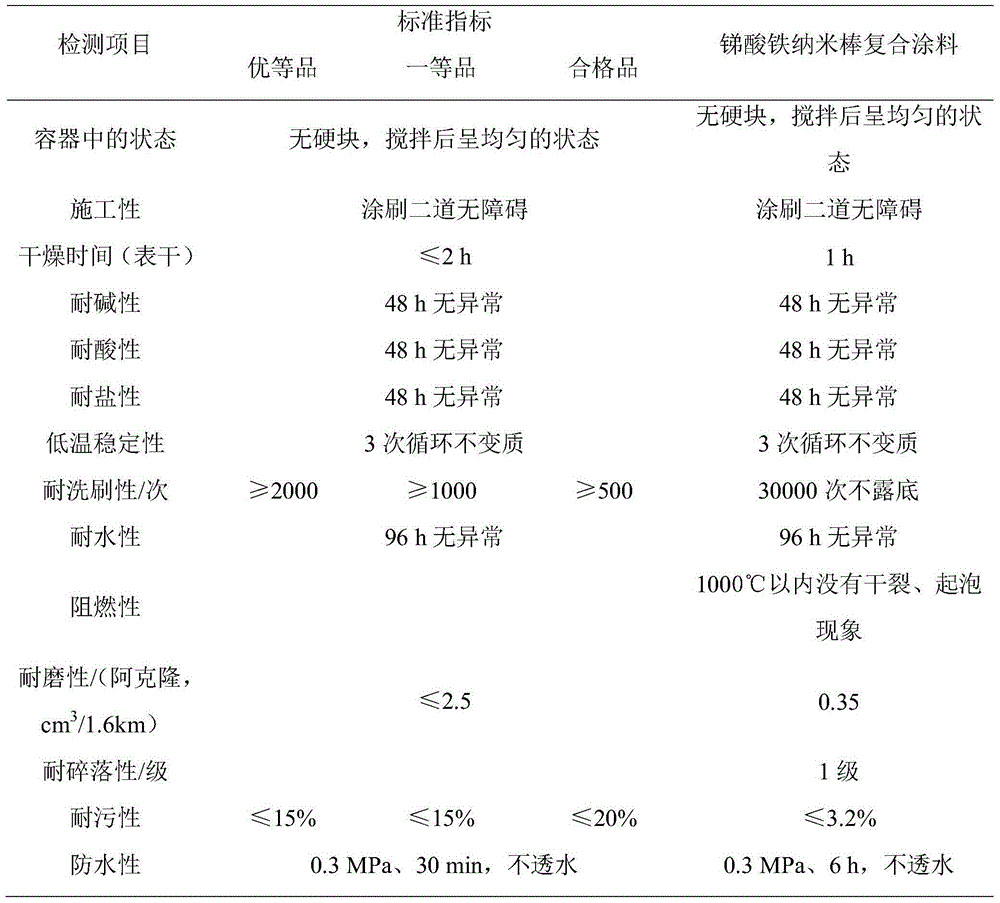

Image

Examples

Embodiment 1

[0020] Determine the mass percentage composition of bismuth nickelate nanowire multifunctional coating as follows:

[0021] Bismuth Nickel Oxide Nanowires 38%

[0022] Nano calcium silicate 6%

[0023] Water-based fluorocarbon emulsion 11%

[0024] Styrene Acrylate Copolymer Emulsion 4%

[0025] Propylene glycol methyl ether acetate 3%

[0026] Hydroxy Silicone Emulsion 8%

[0027] Water 26.15%

[0028] Sodium fatty alcohol polyoxyethylene ether carboxylate 1%

[0030] Organic bentonite 0.3%

[0031] Dimethyl sulfoxide 0.3%

[0032] Polyacrylamide 0.05%

[0033] Ethylene glycol butyl ether acetate 1.2%

[0034] Acrylic resin 0.2%.

Embodiment 2

[0036] Determine the mass percentage composition of bismuth nickelate nanowire multifunctional coating as follows:

[0037] Bismuth Nickel Oxide Nanowires 21%

[0038] Nano Calcium Silicate 10.2%

[0039] Water-based fluorocarbon emulsion 21%

[0040] Styrene Acrylate Copolymer Emulsion 9%

[0041] Propylene glycol methyl ether acetate 8%

[0042] Hydroxy Silicone Emulsion 3%

[0043] water 17%

[0044] Sodium Fatty Alcohol Polyoxyethylene Ether Carboxylate 3%

[0046] Organic bentonite 1%

[0047] DMSO 1%

[0048] Polyacrylamide 0.2%

[0049] Ethylene glycol butyl ether acetate 3%

[0050] Acrylic resin 0.6%.

Embodiment 3

[0052] Determine the mass percentage composition of bismuth nickelate nanowire multifunctional coating as follows:

[0053] Bismuth Nickel Oxide Nanowires 22%

[0054] Nano Calcium Silicate 14%

[0055] Water-based fluorocarbon emulsion 12%

[0056] Styrene Acrylate Copolymer Emulsion 5%

[0057] Propylene glycol methyl ether acetate 4%

[0058] Hydroxy Silicone Emulsion 5%

[0059] water 33%

[0060] Sodium fatty alcohol polyoxyethylene ether carboxylate 1.5%

[0062] Organic bentonite 0.5%

[0063] Dimethyl sulfoxide 0.5%

[0064] Polyacrylamide 0.1%

[0065] Ethylene glycol butyl ether acetate 1.5%

[0066] Acrylic resin 0.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com