Aluminum-based copper-plated graphene film composite material with high heat-conducting property and preparation method thereof

A thin-film composite material, copper-plated graphene technology, applied in electrolytic coatings, coatings, etc., can solve problems such as high price, inability to disperse materials well, large specific gravity, etc., to improve thermal conductivity, simplify galvanizing steps, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

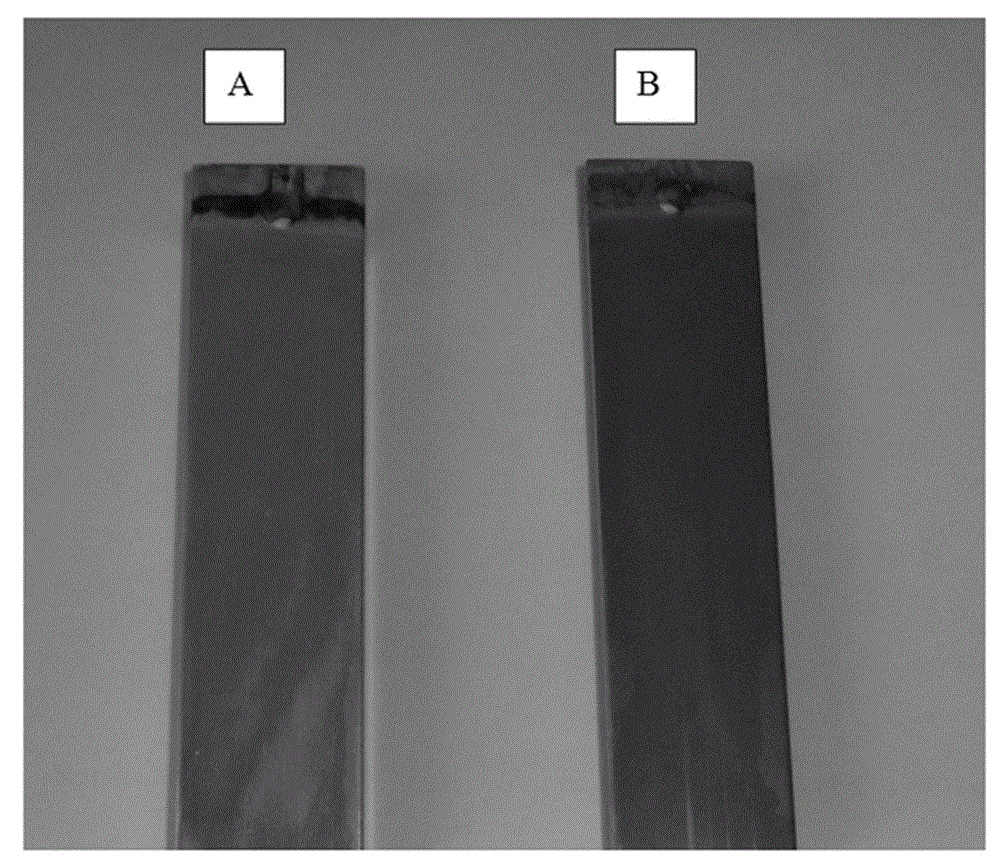

[0037] A method for preparing aluminum-based copper-coated graphene film composite material with high thermal conductivity, comprising the steps of:

[0038] 1) Degrease the aluminum substrate sample in a degreasing solution at 65°C for 3 minutes, and clean it with clean water. Degreasing fluid: sodium carbonate 40g / L, trisodium phosphate 50g / L

[0039] 2) The sample after degreasing is exposed to light at 25°C for 2 minutes, and cleaned with clean water. Light-emitting liquid: nitric acid 500ml / L, hydrofluoric acid 100ml / L

[0040] 3) Dip the sample after exposure to zinc in a zinc dipping solution at 25°C for 2 minutes, and clean it with clean water. Primary zinc dipping solution: 155ml / L hydrofluoric acid, 75g / L boric acid, 6.5g / L zinc oxide

[0041] 4) The sample after the primary zinc dipping is dipped in the secondary zinc dipping solution at 25°C for 2 minutes, and cleaned with clean water. Secondary zinc dipping solution: sodium hydroxide 185g / L, trisodium citrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com