High-stability ceramic honeycomb catalyst and preparation method thereof

A ceramic honeycomb, catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of poor mechanical properties, low catalytic activity, etc., and achieves high catalytic activity. , the effect of excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

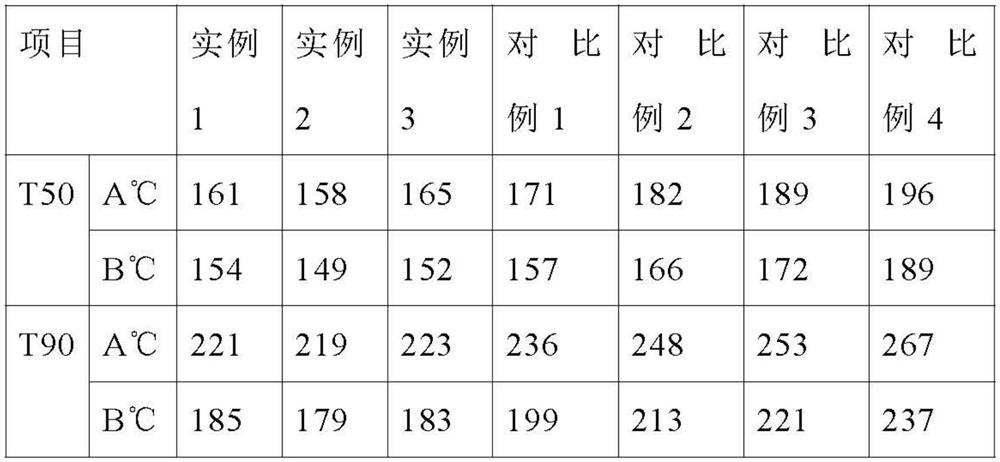

example 1

[0049] S1: Prepare materials:

[0050] S2: Preparation of modified additives:

[0051] Mix polyacrylonitrile, polystyrene, and dimethylformamide, stir in an oil bath at 60°C for 20 hours, and perform electrospinning at a spinning voltage of 7kV to obtain spun fibers, and then place the spun fibers at 270°C to pre- Oxidize for 1 hour, heat up to 900°C under the protection of nitrogen, heat-preserve for 2 hours, cool down and place in concentrated nitric acid for acidification to obtain modified carbon fibers;

[0052] Mix graphene oxide and absolute ethanol, stir and dissolve for 15 minutes, ultrasonically treat for 10 minutes, and then place in a ball mill for ball milling and disperse for 2 hours to obtain a surface treatment agent;

[0053] Take modified carbon fibers, mullite fibers and hollow microspheres, dissolve them in absolute ethanol, mix and stir for 12 hours, then add surface treatment agent, disperse ultrasonically for 10 minutes, and dry in vacuum at 80°C to obt...

example 2

[0063] S1: Prepare materials:

[0064] S2: Preparation of modified additives:

[0065] Mix polyacrylonitrile, polystyrene, and dimethylformamide, stir in an oil bath at 65°C for 22 hours, and perform electrospinning at a spinning voltage of 7kV to obtain spun fibers, which are then preheated at 272°C. Oxidation for 1.1h, heating up to 905°C under nitrogen protection, heat preservation for 2.2h, cooling to acidification in concentrated nitric acid to obtain modified carbon fibers;

[0066] Mix graphene oxide and absolute ethanol, stir and dissolve for 18 minutes, ultrasonically treat for 11 minutes, and place in a ball mill for ball milling and dispersing for 2.1 hours to obtain a surface treatment agent;

[0067] Take modified carbon fibers, mullite fibers and hollow microspheres, dissolve them in absolute ethanol, mix and stir for 13 hours, then add surface treatment agent, ultrasonically disperse for 15 minutes, and vacuum dry at 82°C to obtain modified additives;

[0068]...

example 3

[0077] S1: Prepare materials:

[0078] S2: Preparation of modified additives:

[0079] Mix polyacrylonitrile, polystyrene, and dimethylformamide, stir in an oil bath at 70°C for 24 hours, and perform electrospinning at a spinning voltage of 8kV to obtain spun fibers, and then place the spun fibers at 275°C to pre- Oxidation for 1.2 hours, heating up to 910°C under nitrogen protection, heat preservation for 2.5 hours, cooling to acidification in concentrated nitric acid to obtain modified carbon fibers;

[0080] Mix graphene oxide and absolute ethanol, stir and dissolve for 20 minutes, ultrasonically treat for 12 minutes, and then place in a ball mill to disperse for 2.2 hours to obtain a surface treatment agent;

[0081] Take modified carbon fibers, mullite fibers and hollow microspheres, dissolve them in absolute ethanol, mix and stir for 14 hours, then add surface treatment agent, ultrasonically disperse for 20 minutes, and vacuum dry at 85°C to obtain modified additives; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com