High-fixation-rate non-aqueous solvent dyeing method for reactive dyes

A reactive dye and non-aqueous solvent technology, applied in the field of textile dyeing and finishing, can solve the problems of high affinity of dyes to fibers, high affinity, and large amount of surfactant co-surfactant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The present embodiment provides a kind of reactive dye non-aqueous solvent dyeing method of high fixation rate, specifically comprises the following steps:

[0044] 10g of pure cotton knitted fabric is pretreated in an aqueous sodium hydroxide solution with a concentration of 10g / L, dried, and then put into a dyeing cup;

[0045] Add 0.3g (3% o.m.f) EBR Red 3BS dye and 50mL dimethyl sulfoxide to the dyeing cup, heat up to 95°C at 1°C / min and keep warm for 2h, add 150mL tetrachlorethylene during the heating process, The dye uptake rate is 100%, the solvent is poured out and recovered;

[0046] Add 1g of diethylenetriamine and 100mL of acetone to the dyeing cup, keep it warm at 80°C for 30min, pour out the solvent and recover it;

[0047] Add 1g of cyanuric chloride and 100mL of acetone to the dyeing cup, keep it warm at 80°C for 30min, pour out the solvent and recover it;

[0048] The cotton fabric is taken out, neutralized, washed with water, and dyed.

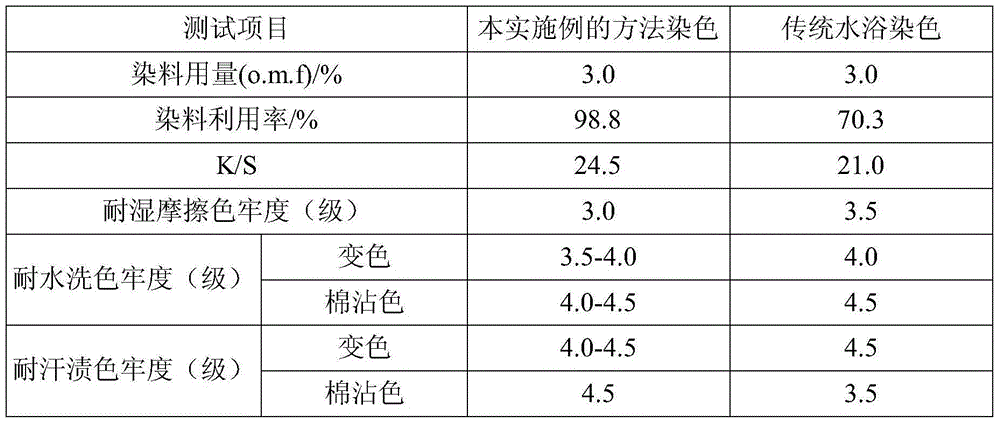

[0049] The c...

Embodiment 2

[0056] The present embodiment provides a kind of reactive dye non-aqueous solvent dyeing method of high fixation rate, specifically comprises the following steps:

[0057] The cotton fabric of 10g is pretreated in the aqueous sodium hydroxide solution of 10g / L by concentration, dries, then puts into the dyeing cup;

[0058] Add 0.3g (3%o.m.f) S S Yellow 3RF dye and 50mL N,N-dimethylformamide to the dyeing cup, raise the temperature to 95°C at 1°C / min and keep it warm for 2h, add 150mL of 1,2-dichloroethane, the dyeing rate is 100%, the solvent is poured out and recovered;

[0059] Add 1g of triethylenetetramine and 100mL of acetone to the dyeing cup, keep it warm at 80°C for 30min, pour out the solvent and recover it;

[0060] Add 1g of adipoyl chloride and 100mL of acetone to the dyeing cup, keep it warm at 80°C for 30min, pour out the solvent and recover it;

[0061] The cotton fabric is taken out, neutralized, washed with water, and dyed.

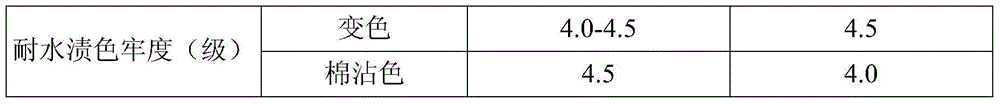

[0062] The color fixing rate o...

Embodiment 3

[0069] The present embodiment provides a kind of reactive dye non-aqueous solvent dyeing method of high fixation rate, specifically comprises the following steps:

[0070] 10g of cotton / nylon (70% cotton+30% nylon) knitted fabric is pretreated in an aqueous sodium hydroxide solution with a concentration of 10g / L, dried, and then put into a dyeing cup;

[0071] Add 0.3g (3%o.m.f) S S Blue BRF dye and 50mL N,N-dimethylacetamide into the dyeing cup, heat up to 95°C at 1°C / min and keep it warm for 2h, add 150mL ten Methylcyclopentasiloxane, the dye uptake rate is 100%, the solvent is poured out and recovered;

[0072] Add 1g of diethylenetriamine and 100mL of acetone to the dyeing cup, keep it warm at 80°C for 30min, pour out the solvent and recover it;

[0073] Add 1g of cyanuric chloride and 100mL of acetone to the dyeing cup, keep it warm at 80°C for 30min, pour out the solvent and recover it;

[0074] The fabric is taken out, neutralized, washed with water, and dyed.

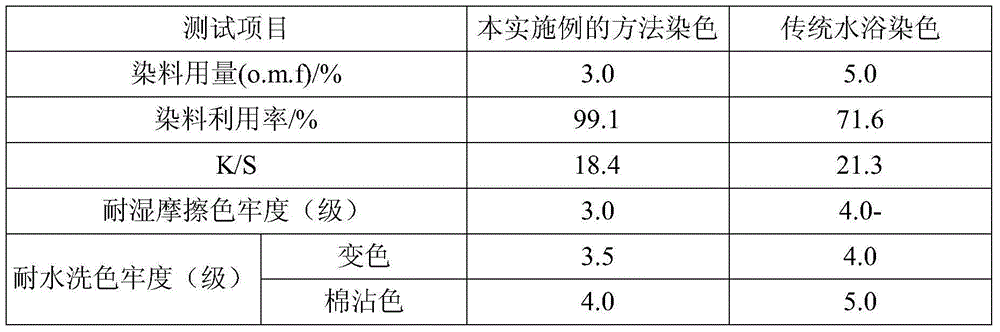

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com