MgO/MgCO3 compound adopting micro-nano hierarchical structure and application of MgO/MgCO3 compound serving as fluorine remover

A hierarchical structure and compound technology, applied in water pollutants, other chemical processes, water/sewage treatment, etc., can solve the problems of poor fluorine adsorption treatment effect, reduced specific surface area, uneven particle size, etc. Fluorine effect, improvement of fluorine removal performance, effect of increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Step 1: First prepare 100 ml of a magnesium nitrate solution with a mass concentration of 3.7% and continue to stir vigorously, then slowly add the prepared 20 ml of a sodium carbonate solution with a mass concentration of 11.7% to the magnesium nitrate solution, and continue stirring for 1 hour;

[0040] Step 2: Transfer the obtained milky white suspension to a water bath device and continue vigorously stirring and reacting at 80°C for 30 minutes;

[0041] Step 3: After the reaction is completed, cool, filter, wash, dry, and sinter at a high temperature of 300 ° C to obtain a micro-nano hierarchical structure MgO / MgCO 3 Compound defluoridation agent.

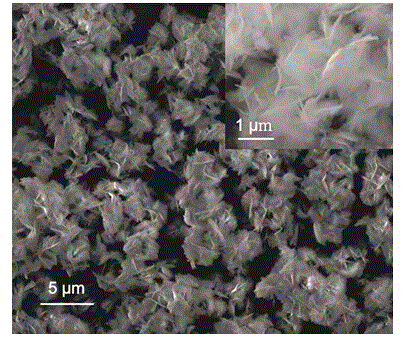

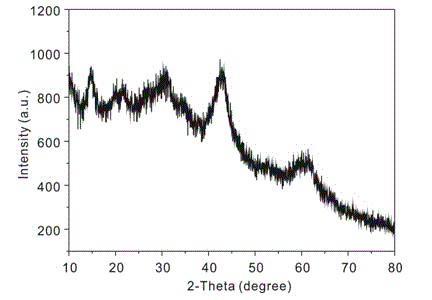

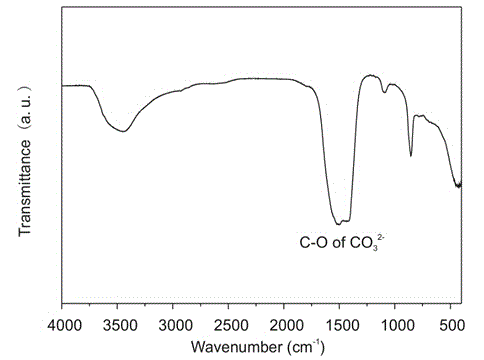

[0042] The morphology of the defluorinating agent was characterized by scanning electron microscopy (such as figure 1 ), it can be seen that it is a micro-nano hierarchical structure; the X-ray diffractometer and Fourier transform infrared spectrometer analysis shows that the material is MgO / MgCO 3 Compounds (such as ...

Embodiment 2

[0045] Step 1: First prepare 100 ml of a magnesium sulfate solution with a mass concentration of 3.0% and continue to stir vigorously, then slowly add the prepared 20 ml of a potassium carbonate solution with a mass concentration of 14.4% to the magnesium sulfate solution, and continue stirring for 1 hour;

[0046] Step 2: Transfer the obtained milky white suspension to a water bath device and continue vigorously stirring and reacting at 80°C for 30 minutes;

[0047] Step 3: After the reaction is completed, cool, filter, wash, dry, and sinter at a high temperature of 300 ° C to obtain a micro-nano hierarchical structure MgO / MgCO 3 Compound defluoridation agent.

[0048] The obtained micro-nano hierarchical structure MgO / MgCO of this example 3 The composite defluoridation agent is applied to the adsorption of fluoride ions in water as follows:

[0049] Step 4: Take 10 g of the obtained micro-nano hierarchical structure MgO / MgCO 3 The composite defluoridation agent was mixed ...

Embodiment 3

[0053] Step 1: First prepare 100 ml of a magnesium chloride solution with a mass concentration of 2.4% and continue to stir vigorously, then slowly add the prepared 20 ml of a sodium carbonate solution with a mass concentration of 11.7% to the magnesium chloride solution, and continue stirring for 1 hour;

[0054] Step 2: Transfer the obtained milky white suspension to a water bath device and continue vigorously stirring and reacting at 80°C for 30 minutes;

[0055] Step 3: After the reaction is completed, cool, filter, wash, dry, and sinter and anneal at a high temperature of 300°C for 4 hours to obtain a micro-nano hierarchical structure MgO / MgCO 3 Compound defluoridation agent.

[0056] The obtained micro-nano hierarchical structure MgO / MgCO of this example 3 The composite defluoridation agent is applied to the adsorption of fluoride ions in water as follows:

[0057] Step 4: 10 g of obtained micro-nano hierarchical structure MgO / MgCO 3 The composite defluoridation agent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com