Heat-pipe-based complementary electricity generation system for preheating condensed water of coal-fired unit through geothermal energy

A technology for coal-fired units and power generation systems, applied in geothermal energy power generation, geothermal energy systems, geothermal energy, etc. Problems such as high mining costs, to achieve the effect of reducing coal consumption, reducing heat load, and reducing investment in power equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

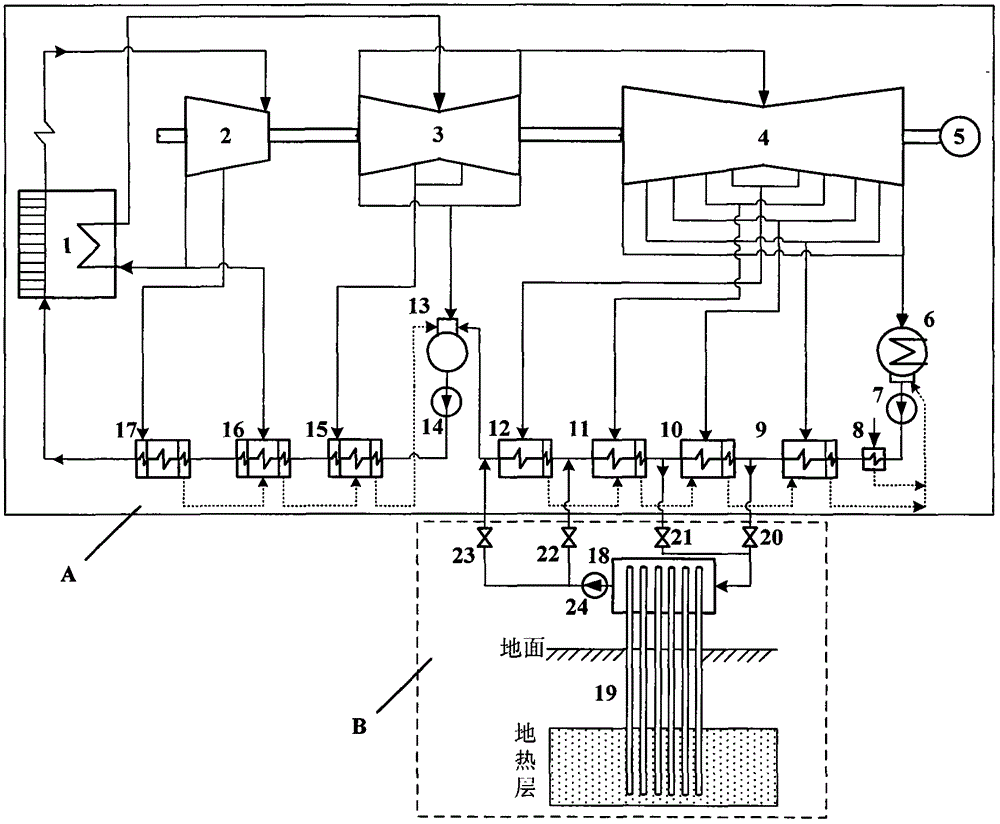

[0034] When the condensing temperature of the heat pipe working medium is high, that is, the operating temperature of the heat pipe heat exchanger 18 is high, valves 21 and 23 are opened, valves 20 and 22 are closed, and the condensed water at the outlet of No. 2 low-pressure heater 10 enters the heat pipe through valve 21 In the heat exchanger 18, the condensed water is heated by the working fluid of the heat pipe to a temperature slightly higher than the outlet temperature of the No. No. low pressure heater 12 outlet, and enter deaerator 13. In this embodiment, the steam extraction required by the low-pressure heaters 11 and 12 is reduced, and the replaced steam returns to the steam turbine to perform work, thereby increasing the power generation of the coal-fired unit. Taking a 1000MW unit as an example, the steam extraction temperature of the low-pressure heater 11 is 134°C, the extraction steam volume is 19.5kg / s, and the outlet temperature is 101°C; the extraction steam ...

Embodiment 2

[0036] When the condensing temperature of the heat pipe working fluid is low, that is, the operating temperature of the heat pipe heat exchanger 18 is low, only valves 20 and 22 are opened, and valves 21 and 23 are closed, and the condensed water at the outlet of No. 1 low-pressure heater 10 enters through the valve 20 In the heat pipe heat exchanger 18, the condensed water is heated by the heat pipe working fluid to a temperature slightly higher than the outlet temperature of the No. Exit 11 of No. 3 low-pressure heater. In this embodiment, the amount of steam extracted by the steam turbines required by the low-pressure heaters 10 and 11 is reduced, and the substituted steam returns to the steam turbines to perform work, increasing the power generation of the unit. Still taking a certain 1000MW unit as an example, the steam extraction temperature of the low-pressure heater 10 is 84°C, the steam extraction rate is 16.6kg / s, and the outlet temperature is 80°C. The water vapor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com