Acetamiprid and emamectin benzoate mixed soluble granular insecticide and preparation method thereof

A technology of emamectin and acetamiprid, which is applied in the field of pesticide formulation and preparation, can solve the problems of high residual toxicity, difficult suspending agent process, and high preparation cost, and achieves the effects of simple processing equipment, making up for its own deficiencies, and remarkable control effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

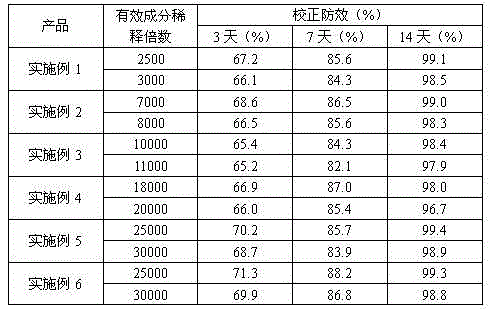

Examples

Embodiment l

[0031] The components are combined in the following weight ratio: 1% emamectin benzoate, 5% acetamiprid, 6% sodium lignosulfonate, 2% sodium p-isopropylnaphthalenesulfonate, 2,6-di-tert-butyl-4 -Methylphenol 1%, polydimethylsiloxane 0.5% and anhydrous lactose 84.5%, each component is coarsely pulverized and then stirred and mixed, and after mixing, it is pulverized by ultra-fine airflow to obtain a particle size of less than 15 microns Ultrafine powder, add 7% ethanol of its total mass in the ultrafine powder, ethanol is used as binder to bind the ultrafine powder together and then carry out kneading and extrusion granulation, the kneading and The granulation process can be completed by using a kneader and a granulator respectively, and the obtained granules are vacuum-dried at a temperature of 55° C. for 2 hours and then sieved to obtain a soluble granule product after sieving. The product is packaged after passing the test.

Embodiment 2

[0033] The components are combined in the following weight ratio: emamectin benzoate 5%, acetamiprid 15%, alkylnaphthalene sulfonate sodium formaldehyde condensate 7%, sodium p-dodecyl sulfate 3%, sodium benzoate 1%, fluorosilicone Oxygen 0.8% and soluble starch 68.2%, each component is coarsely pulverized and then stirred and mixed, after mixing, it is pulverized by ultra-fine airflow to obtain an ultra-fine powder with a particle size of less than 15 microns, and add other components to the ultra-fine powder 10% of the total mass of methanol, methanol is used as a binder to bond the ultrafine powder together and then kneaded and extruded to granulate. The obtained particles are vacuum-dried at 60°C for 1.5 hours and then sieved. After sieving, the soluble granule product is obtained. The product is packaged after passing the test, and the unqualified product is crushed, kneaded and extruded to granulate, vacuum-dried at 60°C for 1.5 hours, and then sieved, and the sieved pro...

Embodiment 3

[0035] The components are combined in the following weight ratio: 10% emamectin benzoate, 30% acetamiprid, 10% acrylic acid-maleic acid copolymer, 4% sodium butylnaphthalene sulfonate, 1.5% sodium dihydrogen phosphate, ethylene glycol silicon Oxane 0.5% and sodium citrate 44%, each component is coarsely pulverized and then stirred and mixed, after mixing, it is pulverized by ultra-fine airflow to obtain an ultra-fine powder with a particle size of less than 15 microns. Add to the ultra-fine powder Its total mass is 8% ethanol, and ethanol is used as a binder to bond the ultrafine powder together and then kneaded and extruded to granulate. The obtained particles are vacuum-dried at 65°C for 1 hour and then sieved. After sieving, the soluble granule product is obtained. The product is packaged after passing the test, and the unqualified product is crushed, kneaded and extruded to granulate, vacuum-dried at 65°C for 1 hour, and then sieved, and the sieved product is packaged afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com