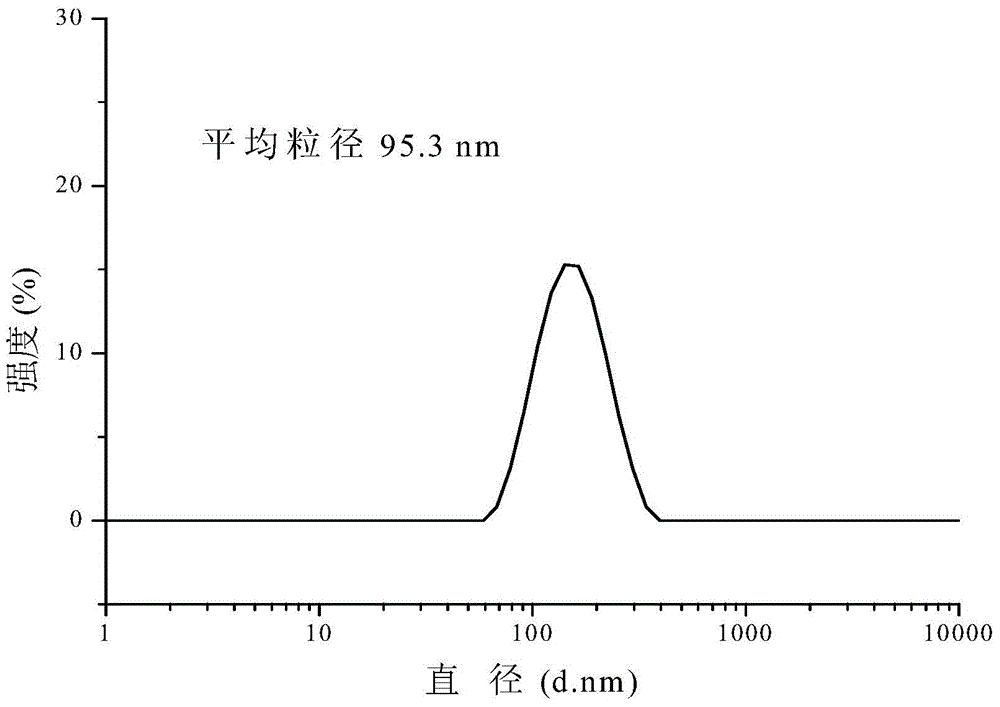

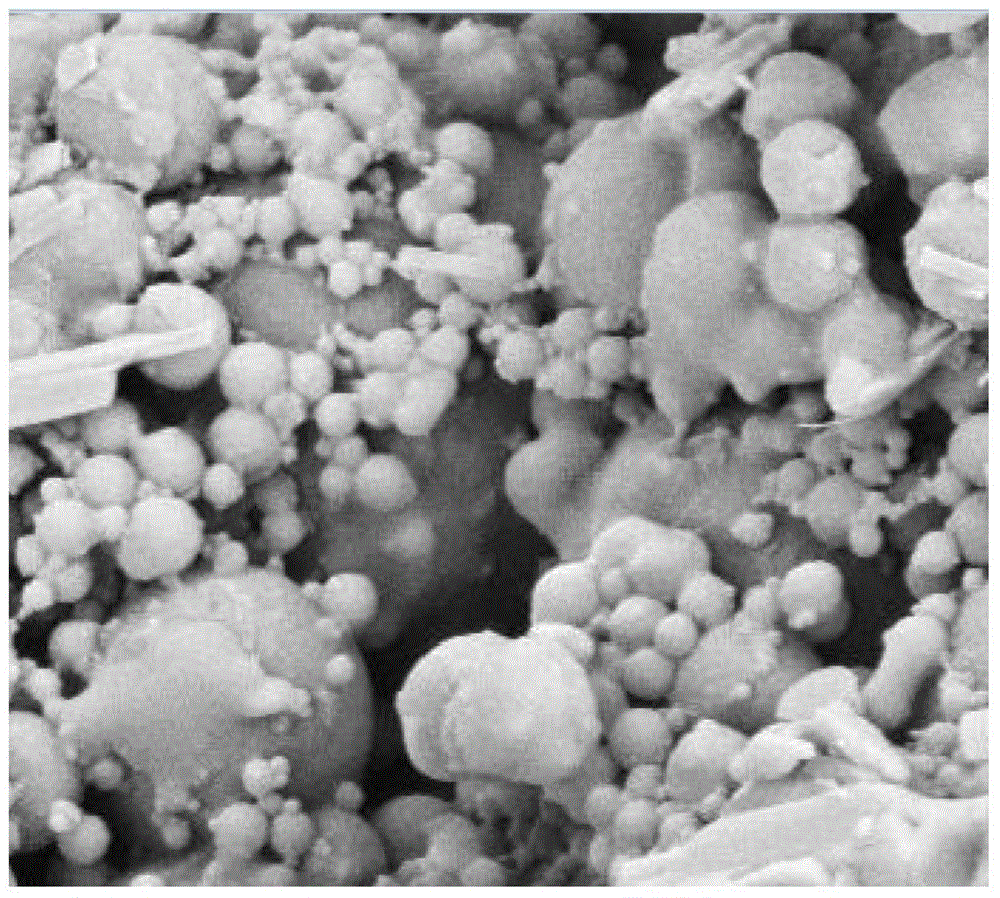

Preparation method of starch nanometer microspheres based on ionic liquid-type surfactant microemulsion system

A surfactant and ionic liquid technology, applied in the field of preparing starch nano-microspheres by microemulsion cross-linking method, can solve the problems of wide particle size distribution, large starch particle size, clinical application limitations, etc., and achieve good biocompatibility , the effect of mild reaction conditions and simple process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The first step is to dry the soluble starch raw material at 50°C until the moisture content is less than 3%;

[0031] The second step is to use 2mol / L sodium hydroxide to make the soluble starch raw material obtained in step (1) into starch milk with a mass percentage concentration of 3%, and heat and stir at a constant temperature of 90°C until it is completely dissolved;

[0032] The third step is to lower the solution obtained in step (2) to room temperature, first add cyclohexane, and then slowly add ionic liquid surfactant C 16 The mixture of mimBr and co-surfactant n-butanol is clear to the solution, and no starch granules are separated out to prepare water-in-oil ionic liquid microemulsion; the starch solution mass ratio of hexamethylene and step (2) gained is 7:3, ionic liquid surfactant C 16 mimBr is mixed with the co-surfactant n-butanol in a mass ratio of 3:1, and the sum of the mass of the two accounts for 20% of the mass of the ionic liquid microemulsion i...

Embodiment 2

[0036] The first step is to dry the soluble starch raw material at 60°C until the moisture content is less than 3%;

[0037] The second step is to use 2mol / L sodium hydroxide to make the soluble starch raw material obtained in step (1) into starch milk with a mass percentage concentration of 10%, and heat and stir at a constant temperature of 80°C until it is completely dissolved;

[0038] The third step is to lower the solution obtained in step (2) to room temperature, first add cyclohexane, and then slowly add ionic liquid surfactant C 16 The mixture of mimBr and co-surfactant n-butanol is clarified to the solution, and the water-in-oil ionic liquid microemulsion is prepared; the starch solution mass ratio of hexamethylene and step (2) gained is 7:3, ionic liquid type surfactant C 16 mimBr is mixed with the co-surfactant n-butanol in a mass ratio of 4:1, and the sum of the mass of the two accounts for 30% of the mass of the ionic liquid microemulsion in oil;

[0039] The four...

Embodiment 3

[0042] The first step is to dry the soluble starch raw material at 70°C until the moisture content is less than 3%;

[0043] The second step is to use 2mol / L sodium hydroxide to make the soluble starch raw material obtained in step (1) into starch milk with a mass percentage concentration of 8%, and heat and stir at a constant temperature of 70°C until it is completely dissolved;

[0044] The third step is to lower the solution obtained in step (2) to room temperature, first add cyclohexane, and then slowly add ionic liquid surfactant C 16 The mixture of mimBr and co-surfactant n-butanol is clarified to the solution, and the water-in-oil ionic liquid microemulsion is prepared; the starch solution mass ratio of hexamethylene and step (2) gained is 7:3, ionic liquid type surfactant C 16 mimBr is mixed with the co-surfactant n-butanol at a mass ratio of 5:1, and the sum of the mass of the two accounts for 40% of the mass of the ionic liquid in oil microemulsion;

[0045] The fou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com