A kind of preparation method of nuclear fuel cladding element

A technology for cladding elements and nuclear fuels, which is applied in the field of preparation of ceramic cladding tubes for nuclear fuels, can solve problems such as non-protective properties, achieve a simple and easy method, good mechanical properties and thermal conductivity, and overcome the effects of difficult processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] In this example, using Ti 3 SiC 2 Materials for the preparation of nuclear fuel cladding tubes.

[0052] First to commercial Ti 3 SiC 2 The bulk ceramic materials were subjected to the corrosion resistance test of molten fluorine salts.

[0053] The commercial Ti 3 SiC 2 The bulk ceramic material is prepared by powder sintering method, specifically: Weigh an appropriate amount of commercial Ti 3 SiC 2 Powder, the Ti 3 SiC 2 The powder is put into a graphite mold and pressurized in one direction to form a green body, and then put into a spark plasma sintering (SPS) furnace, heated to 1200°C in a vacuum state, and a pressure of 40MPa is applied, and the holding time is 5min.

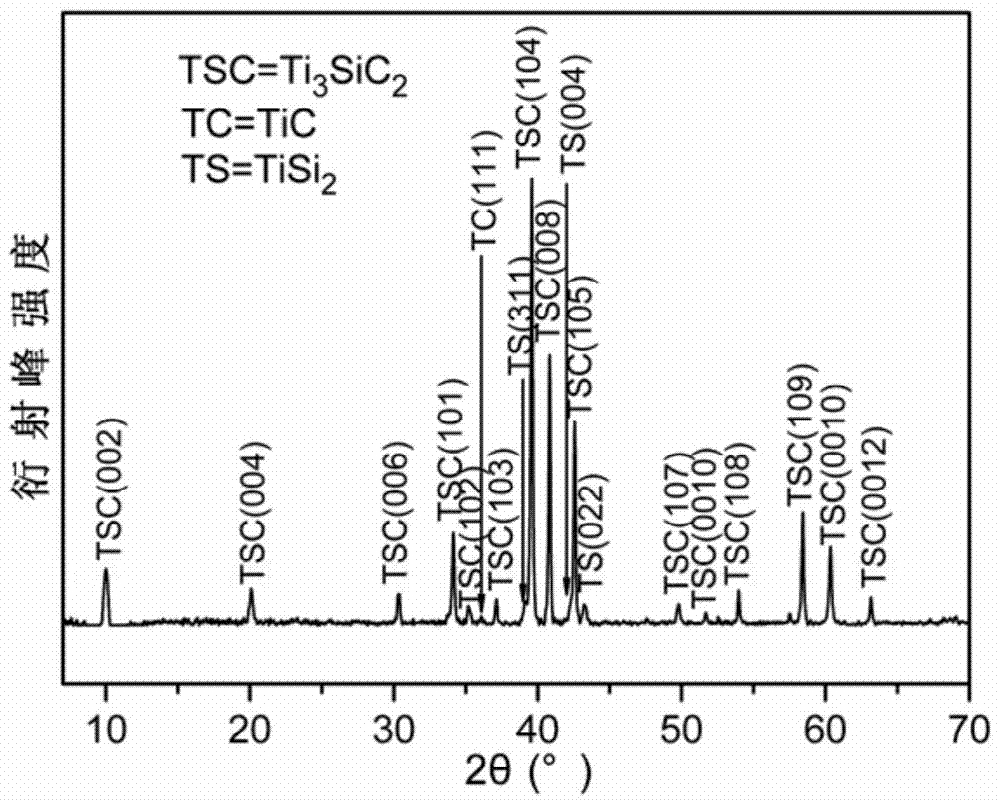

[0054] For the Ti prepared above 3 SiC 2 The phase of the bulk material is measured and analyzed, and its XRD spectrum is as follows figure 1 As shown, it can be seen that the bulk material has high purity and low impurity content.

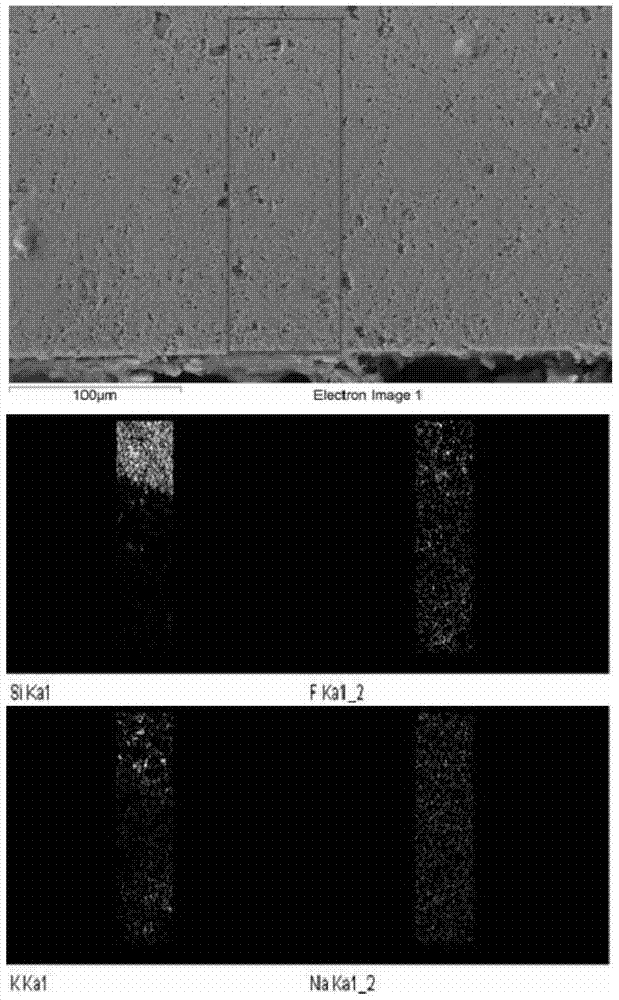

[0055] The Ti 3 SiC 2 The test method for the corro...

Embodiment 2

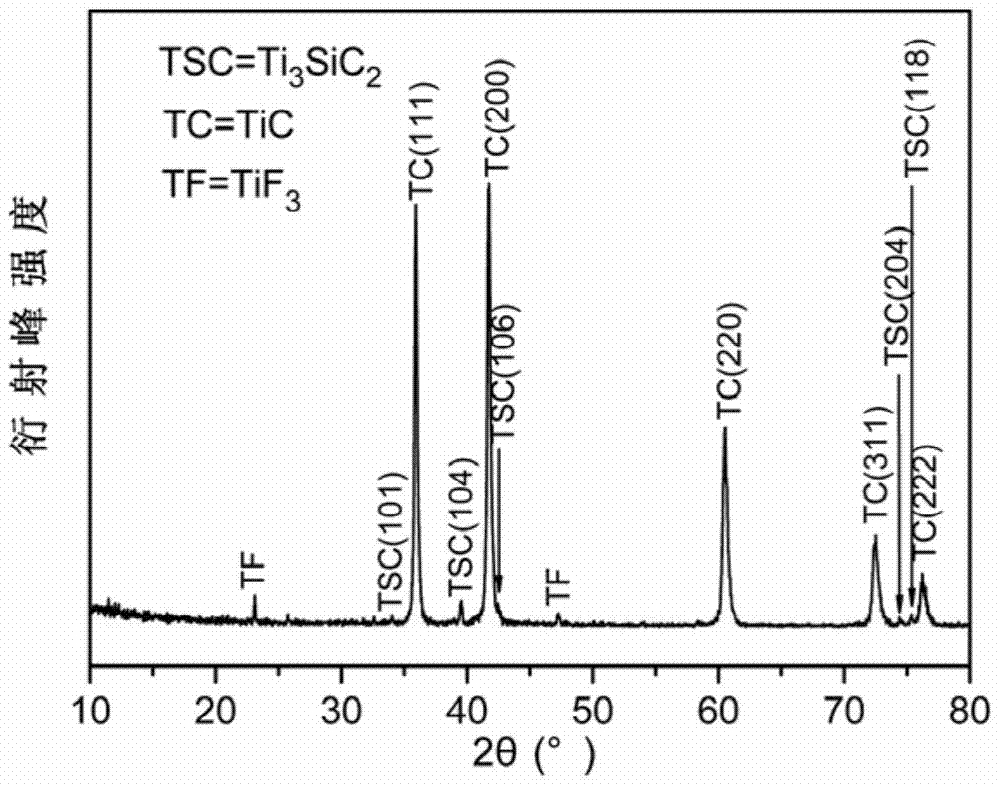

[0071] In this embodiment, first for Ti 3 SiC 2 -10wt% SiC composite bulk material was tested for corrosion resistance to molten fluorine salts.

[0072] The composite material is Ti 3 SiC 2 -10wt% SiC, the subsequent corrosion test was carried out in FLINAK molten salt at 700 °C, and the corrosion time was 8 days (192h). The specific process is as follows:

[0073] The Ti 3 SiC 2 -10wt%SiC composite bulk material with Ti 3 SiC 2 The ceramic material is used as a matrix, and SiC is used as a composite phase, and the composite phase accounts for 10wt% of the content of the matrix.

[0074] The composite block material is prepared by powder sintering method, specifically: Weigh an appropriate amount of commercial Ti 3 SiC 2 and SiC powder, mixed by ball milling, dried and put into a graphite mold, first pressurized in one direction to form a green body, and then put into a spark plasma sintering (SPS) furnace, heated to 1350°C under the protection of Ar atmosphere, and...

Embodiment 3-11

[0089] Similar to the above-mentioned Examples 1 and 2, the nuclear fuel cladding tubes were prepared by the same method in Examples 3-11 respectively, and the parameters such as raw materials, dispersants, plasticizers, binders, and sintering methods are as follows:

[0090]

[0091] Among them, SiC(f) represents silicon carbide fiber material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com