Homopolymer nanovesicles and its preparation method and application

A technology of nanovesicles and homopolymers, applied in chemical instruments and methods, alkali metal compounds, and other chemical processes, can solve the problems of easy aggregation of gold nanoparticles, waste of energy, performance discount, etc., and achieve simple preparation steps, Guaranteed stability and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035]

[0036] The preparation method of homopolymer nanovesicle comprises the following steps:

[0037] (1) Synthetic steps of homopolymer:

[0038] Dissolve the chain transfer agent in the first organic solvent, add the initiator and polymerized monomer, use the bubbling method to deoxygenate for 30 minutes to remove the dissolved oxygen, and then react at 50-130°C for 8-28 hours. Precipitate in cyclohexane for 3 times, and dry in a vacuum oven for 24 hours to obtain a homopolymer;

[0039] (2) Preparation steps of homopolymer nanovesicles (co-solvent method):

[0040] Dissolve the homopolymer obtained in step (1) in the second organic solvent (to make the concentration of the homopolymer reach 0.1-1.0mg / mL), and drop twice the amount of The deionized water with the volume of the second organic solvent is continuously added with deionized water twice the volume of the second organic solvent to quench, and the homopolymer nanovesicle solution is obtained after dialysis. ...

Embodiment 1

[0058] This embodiment provides a method for preparing homopolymer nanovesicles, comprising the following steps:

[0059] (1) Synthetic steps of homopolymer:

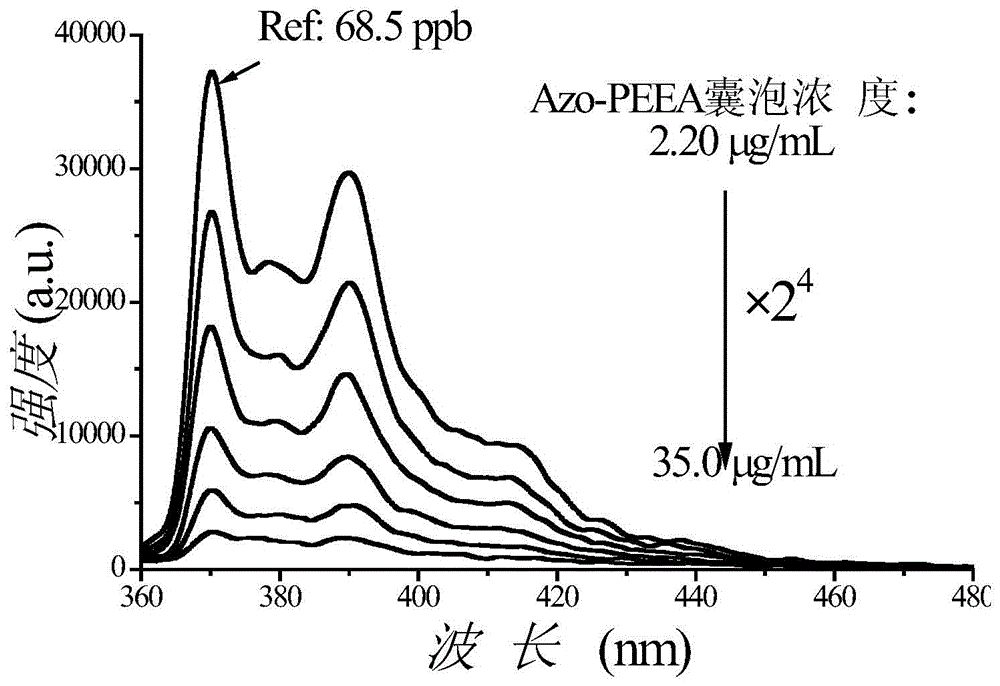

[0060] The chain transfer agent Azo-DDMAT (0.589g, 1mmol) was dissolved in 2mL of dimethylformamide, and the initiator azobisbutyronitrile (0.164g, 1mmol) and the polymerization monomer 2-(2-ethoxy Ethoxy)ethyl acrylate (1.882g, 10mmol), deoxygenated by bubbling method for 30min, reacted at 50°C for 28h, precipitated in cyclohexane for 3 times after the reaction, dried in a vacuum oven for 24h , to obtain a pure homopolymer.

[0061] (2) Preparation steps of homopolymer nanovesicles:

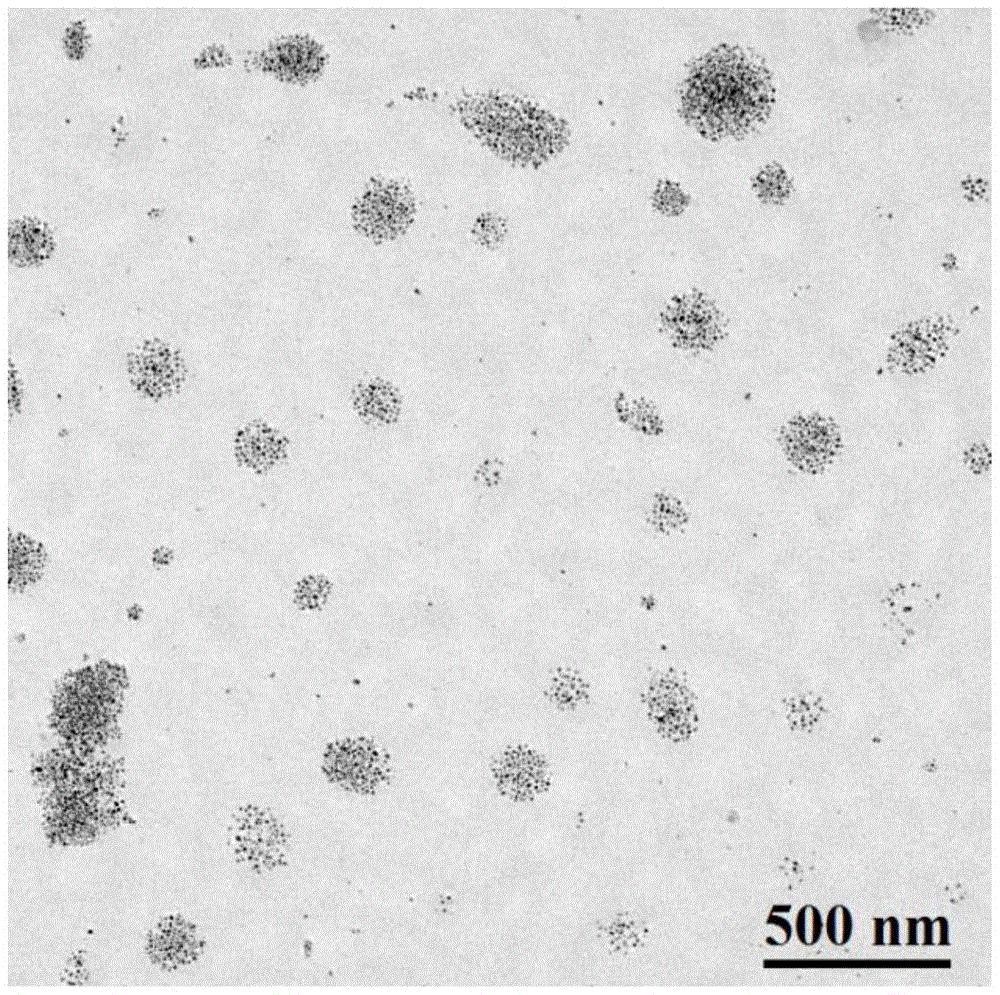

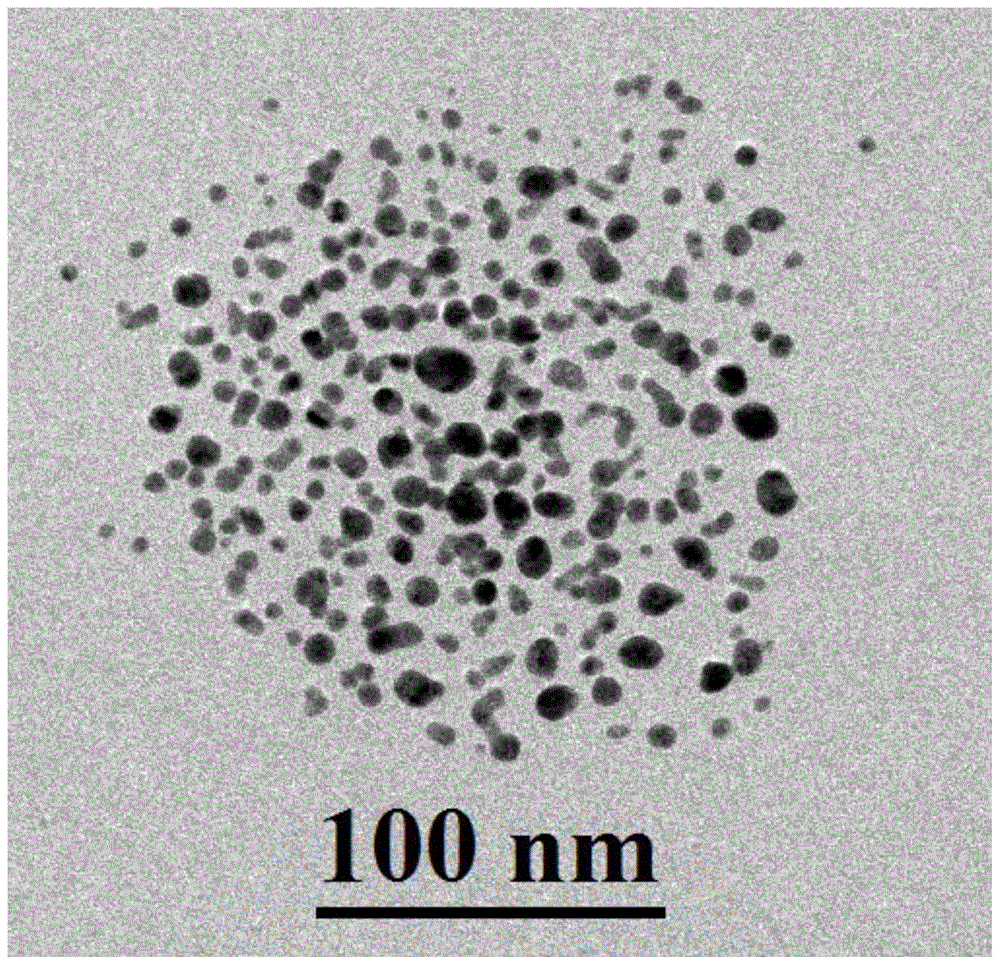

[0062] Dissolve the homopolymer obtained in step (1) in tetrahydrofuran (to make the concentration of the homopolymer reach 0.1 mg / mL), and add deionized water twice the volume of the above tetrahydrofuran dropwise at a speed of 15 d / min under vigorous stirring , and then add deionized water twice the volume of tetrahydrofuran to quenc...

Embodiment 2

[0069] This embodiment provides a method for preparing homopolymer nanovesicles, comprising the following steps:

[0070] (1) Synthetic steps of homopolymer:

[0071] The chain transfer agent Azo-DDMAT (0.295g, 0.5mmol) was dissolved in 2mL dimethyl sulfoxide, and the initiator azobisbutyronitrile (0.082g, 0.5mmol) and the polymerization monomer 2-(2-ethoxy (1.882g, 10mmol) ethyl acrylate (1.882g, 10mmol), deoxygenated by bubbling for 30min, reacted at 80°C for 20h, precipitated in cyclohexane for 3 times after the reaction, and dried in a vacuum oven After 24h, a pure homopolymer was obtained.

[0072] (2) Preparation steps of homopolymer nanovesicles:

[0073] Dissolve the homopolymer obtained in step (1) in dimethylformamide (to make the concentration of the homopolymer reach 0.4mg / mL), and drop twice the amount of the above-mentioned dimethylformamide at a speed of 24d / min under vigorous stirring. Dimethylformamide volume of deionized water, then add deionized water twi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com