Silicone rubber based ablation-resisting heat insulation composite material and preparation method thereof

A composite material and silicone rubber technology, which is applied in the field of silicone rubber-based ablation-resistant thermal insulation composite materials and their preparation, can solve the problems of difficult formation of carbonized layer, low strength, and low carbon residue rate, and achieve enhanced ablation resistance and Oxidation resistance, strength and density improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

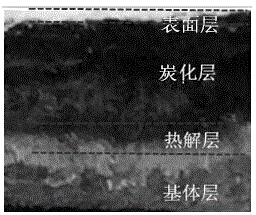

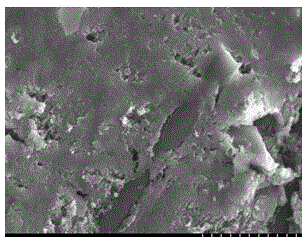

[0036] The silicone rubber-based ablation-resistant and heat-insulating composite material of this embodiment is composed of 100 parts by mass of silicone rubber methyl vinyl silicone rubber, 5 parts by mass of ablation-resistant fiber 6mm chopped carbon fiber, 30 parts by mass of fumed silica, 2 mass parts of structure control agent hydroxyl silicone oil, 15 mass parts of ceramized powder magnesium oxide and 15 mass parts of zirconia, 5 mass parts of carbide carbon nanotubes and 5 mass parts of acetylene carbon black, 10 mass parts of coupling agent KH-560 and The vulcanizing agent dicumyl peroxide is composed of 0.5 parts by mass, the tensile strength of its molded product is 6.78 MPa, the elongation at break is 424%, and the line ablation rate is 0.055mm / s. Its macroscopic picture after ablation test for figure 1 , SEM picture as figure 2 shown, from figure 1 with figure 2 It can be seen that the silicone rubber-based ablation-resistant thermal insulation composite mat...

Embodiment 2

[0044] The silicone rubber-based ablation-resistant and heat-insulating composite material of this embodiment is composed of 50 parts by mass of silicone rubber methyl vinyl silicone rubber, 50 parts by mass of methylphenyl vinyl silicone rubber, and 6 mm chopped aramid fiber of ablation resistance. 15 parts by mass of fiber, 10 parts by mass of precipitated white carbon black, 0.5 parts by mass of structural control agent hydroxy silicone oil, 10 parts by mass of ceramic powdered alumina and 40 parts by mass of calcium oxide, 15 parts by mass of carbonized nano-graphite powder and 15 parts by mass of graphene Parts by mass, 20 parts by mass of coupling agent KH-570 and 2 parts by mass of vulcanizing agent Shuangwuwu, the tensile strength of the molded product is 6.57MPa, the elongation at break is 487%, and the linear ablation rate is 0.041mm / s .

[0045] Its preparation method, carry out according to the following steps:

[0046] (1) According to silicone rubber: 50 parts by ...

Embodiment 3

[0052] The silicone rubber-based ablation-resistant and heat-insulating composite material of this embodiment is composed of 100 parts by mass of silicone rubber methyl phenyl vinyl silicone rubber, 5 parts by mass of ablation-resistant fiber 6mm chopped carbon fiber and 25 parts by mass of polysulfone fiber , 30 parts by mass of fumed silica and 50 parts by mass of precipitated silica, 10 parts by mass of phenyl silicone oil as a structural control agent, 5 parts by mass of ceramic powdered titanium oxide, 1 part by mass of carbonized acetylene carbon black, and a coupling agent Composed of 1 mass part of KH-550, 1 mass part of hexamethyldisilazane and 15 mass parts of vulcanizing agent benzoyl peroxide, the tensile strength of the molded product is 7.57MPa, the elongation at break is 387%, and the wire firing The corrosion rate is 0.027mm / s.

[0053] Its preparation method, carry out according to the following steps:

[0054] (1) According to 100 parts by mass of silicone r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Wire ablation rate | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com