Preparation method of bionic artificial nerve scaffold established by collagen

A collagen and artificial nerve technology, applied in the field of bionic artificial nerve scaffold preparation, can solve the problems of host immune rejection, easy collapse, complicated material extraction and purification, etc., and achieve the effect of low immune rejection and high mechanical strength of degradable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) Prepare a collagen solution with a concentration of 20mg / ml (made from commercially available collagen powder and water), pour it into a mold and freeze at -20°C for 1 hour, and then put it in a freeze dryer vacuum-70°C for 20 minutes ; Take out the columnar collagen material with a length of 1cm and a diameter of 1mm;

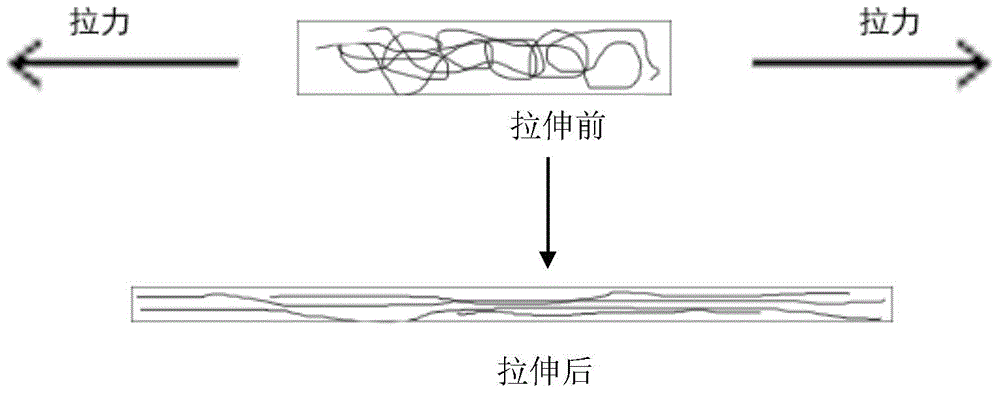

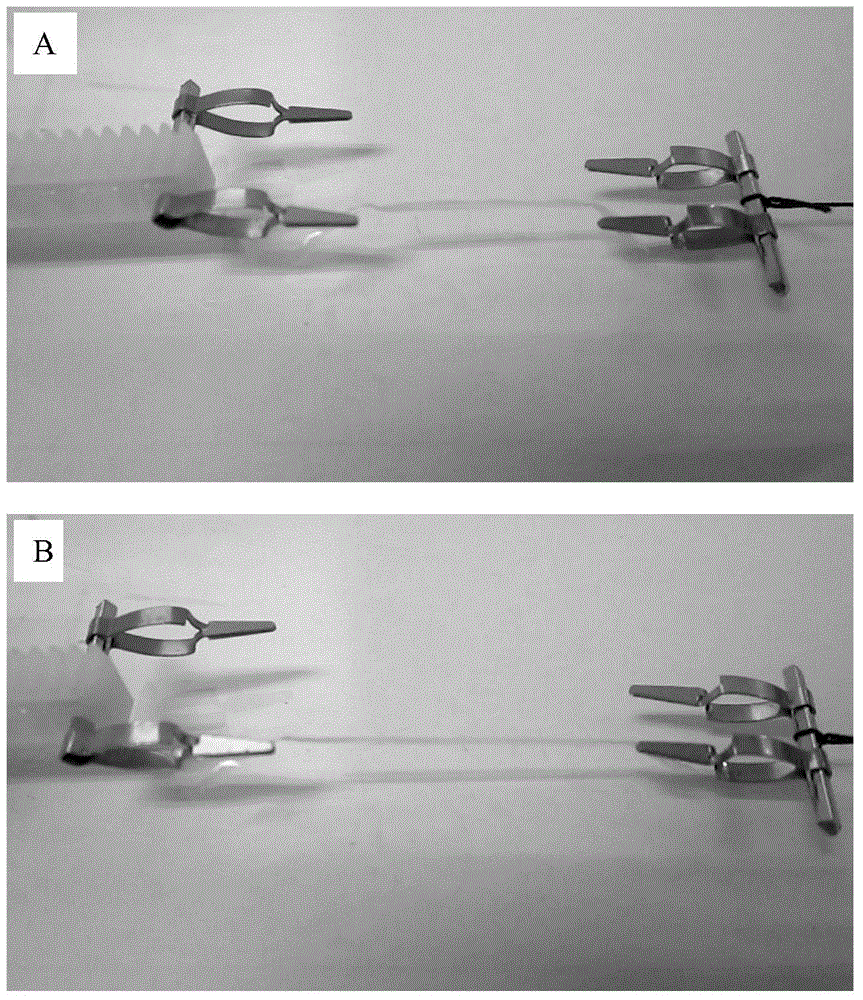

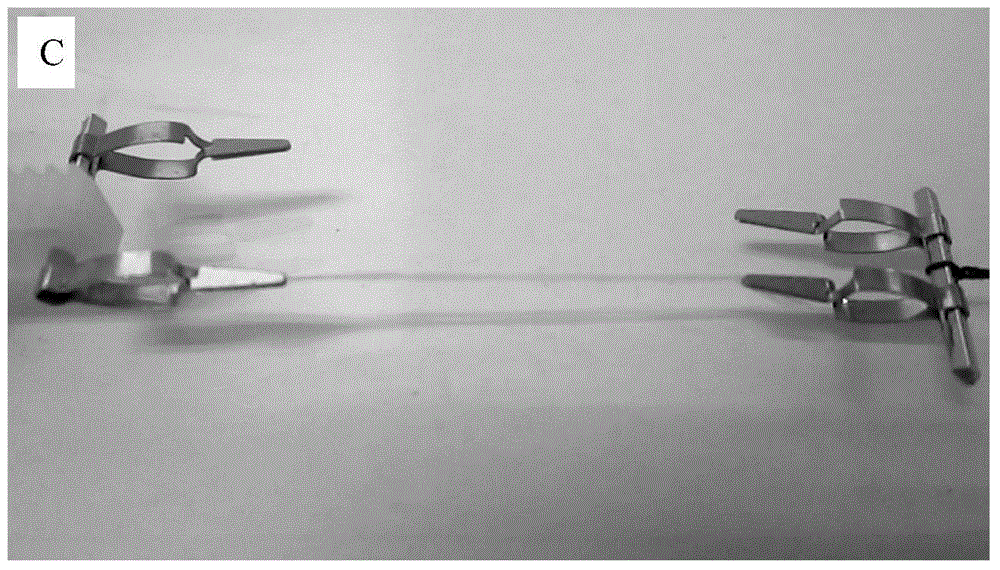

[0034] 2) The above-mentioned collagen material is slowly stretched to twice its original length at a speed of 1.2mm per second (drawing equipment) (the existing equipment on the market, and the American Sutter Instrument P97 programmable horizontal microelectrode drawing instrument can be used). Schematic diagram such as figure 1 As shown), the specific change process of collagen material in the stretching process is as follows figure 2 As shown in A~C, then freeze together with the equipment at -20°C for 1 hour, and then place it in vacuum -70°C for a second freeze-drying for 2 hours to obtain a linear scaffold with orderly microtubes inside (that is,...

Embodiment 2

[0043] 1) Preparation of ordered collagen scaffold: prepare a collagen solution with a concentration of 25mg / ml, pour it into a mold, freeze at -15°C for 80 minutes, and then put it in a freeze dryer vacuum -60°C for 25 minutes; take it out to be 1.2cm long Columnar collagen material with a diameter of 1.2mm;

[0044] 2) The above-mentioned collagen material is slowly stretched to 2.5 times the original length at a speed of 1.4mm per second with a drawing equipment, and then in the stretched state, it is frozen at -15°C for 80 minutes, and then put in a vacuum -80 Perform a second freeze-drying at ℃ for 1.5 hours to obtain a linear scaffold containing ordered micropipes inside, that is, an ordered collagen scaffold, ready for use;

[0045] 3) Preparation of nanofiber film: dissolve the collagen powder with hexafluoroisopropanol, and the concentration of collagen in the solution obtained is 80mg / ml. The solution is made into a nanofiber film with a thickness of 2.2mm by electrospinn...

Embodiment 3

[0049] 1) Preparation of ordered collagen scaffold: prepare a collagen solution with a concentration of 15mg / ml, pour it into a mold and freeze at -25°C for 60 minutes, then put it in a freeze dryer and freeze-dry at -80°C for 15 minutes; take it out to a length of 0.8cm Columnar collagen material with a diameter of 0.8mm;

[0050] 2) The above-mentioned collagen material is slowly stretched to 1.5 times the original length at a speed of 1mm per second with a drawing equipment, and then in the stretched state, it is placed at -25°C and frozen for 60 minutes, and then placed in a vacuum at -60°C Perform a second freeze-drying for 2.5 hours to obtain a linear scaffold containing ordered micropipes inside, that is, an ordered collagen scaffold, ready for use;

[0051] 3) Preparation of nanofiber film: dissolve the collagen powder with hexafluoroisopropanol, and the concentration of collagen in the solution obtained is 120mg / ml. The solution is made into a nanofiber film with a thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com