Preparation method of dye functional magnetic nano material and application in fluorescent sensing and magnetic separation of TNT

A technology of magnetic nano and nano materials, applied in material excitation analysis, chemical instruments and methods, material analysis by optical means, etc., can solve the problems of small adsorption capacity, weak mass transfer ability, and non-selective adsorption, etc. Low cost, convenient regeneration method, and easy-to-achieve effect of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

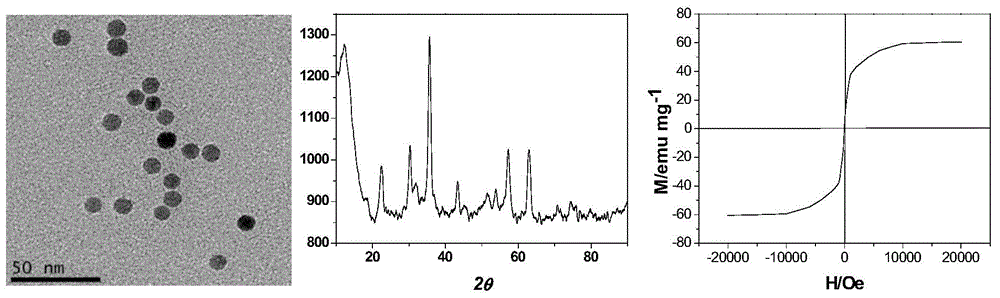

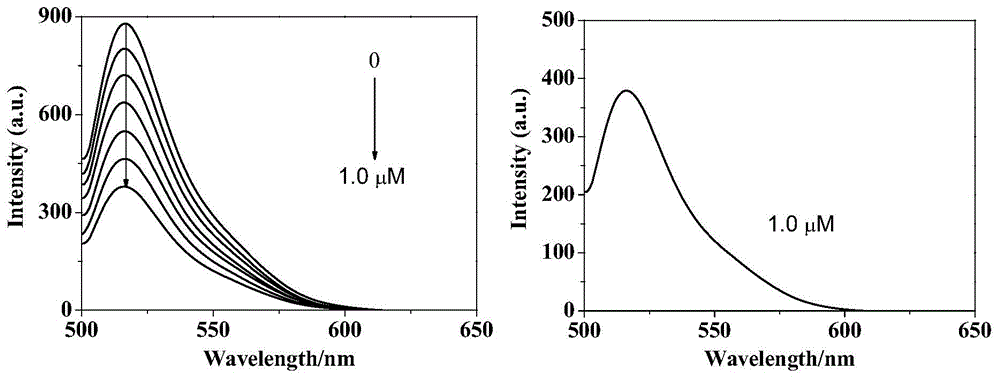

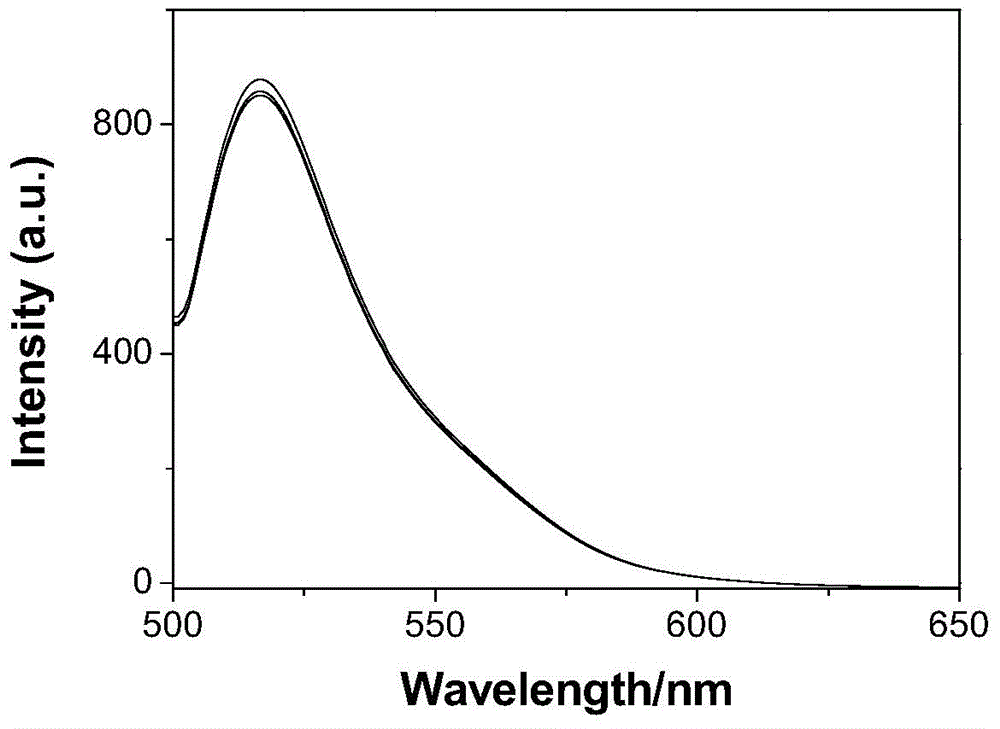

[0030] In this example, dye-functionalized magnetic nanomaterials were prepared according to the following steps:

[0031] (1) Weigh 4.0 mmol of iron oleate complex and 20 ml of oleylamine into a 100 ml flask, add 6 ml of oleic acid and heat to 120° C., stir until the iron oleate complex dissolves to obtain a mixed solution;

[0032] (2) The temperature of the mixed solution was raised to 200°C, dehydrated with nitrogen and kept for 2 hours, then the temperature of the solution was continued to be raised to 300°C, and kept for 2 hours;

[0033] (3) naturally cool to room temperature, filter to obtain the precipitate, and then wash with deionized water and absolute ethanol for 3 to 5 times;

[0034] (4) placing the precipitate in a vacuum drying oven and drying at a temperature of 50° C. for 6 hours to obtain ferric oxide nanomaterials coated with oleic acid;

[0035] (5) 2-ethylamine phosphate is dissolved in anhydrous ethyl ether to obtain a mass concentration of 5% 2-ethyla...

Embodiment 2

[0043] (1) Weigh 6 millimoles of iron oleate complex and 40 ml of oleylamine into a 100 ml flask, add 15 ml of oleic acid and heat to 120°C, stir until the iron oleate complex dissolves to obtain a mixed solution;

[0044] (2) The temperature of the mixed solution was raised to 200°C, dehydrated with nitrogen and kept for 2 hours, then the temperature of the solution was continued to be raised to 320°C, and kept for 2 hours;

[0045] (3) naturally cool to room temperature, filter to obtain the precipitate, and then wash with deionized water and absolute ethanol for 3 to 5 times;

[0046] (4) placing the precipitate in a vacuum drying oven and drying at a temperature of 60° C. for 6 hours to obtain ferric oxide nanomaterials coated with oleic acid;

[0047] (5) 2-ethylamine phosphate is dissolved in anhydrous ethyl ether to obtain a mass concentration of 4% 2-ethylamine phosphate ether solution, and the ferric oxide nanomaterial coated with oleic acid is dispersed in amine 2-ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com