A method for strengthening the surface properties of carbon steel workpieces

A technology of workpiece surface and carbon steel, which is applied in the field of strengthening the surface performance of carbon steel workpieces, can solve the problems of high cost, expensive equipment, and low production efficiency, and achieve fine and compact structure, high energy utilization rate, and improved surface hardness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

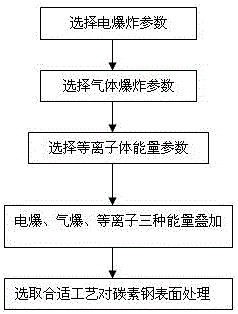

Method used

Image

Examples

example 1

[0029] (1) Select carbon tool steel T8 paper cutter as the processing object, and select tungsten alloy wire with a diameter of Ф8mm as the consumable metal electrode wire;

[0030] (2) Propane is selected as the combustible gas and mixed with oxygen in proportion C3H8:O2=1:5. The process parameters are set as follows: mixed gas pressure 0.35MPa, flow rate 23L / min.

[0031] (3) Select 5kv pulse high voltage power supply;

[0032] (4) Three kinds of energy superposition of electric explosion, gas explosion and plasma are used to treat the surface of T8 paper cutter. Adjust the distance between the nozzle of the pulse plasma gun and the paper cutter to 50mm, and the high-energy particle jet bombards the surface of the paper cutter in the atmospheric environment with a pulse frequency of 5HZ, and the sample processing time is 30s;

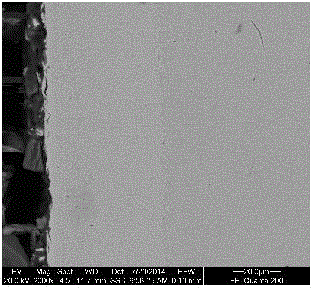

[0033] Using a scanning electron microscope (SEM) to observe the cross-sectional morphology of the T8 paper cutter after treatment, through figur...

example 2

[0038] (1) Select carbon tool steel T10 tap as the processing object, and select tungsten alloy wire with a diameter of Ф4mm as the consumable metal electrode wire;

[0039] (2) Choose methane as the combustible gas and mix it with oxygen in proportion CH4:O2=1:3.5. The process parameters are set as follows: mixed gas pressure 0.5MPa, flow rate 35L / min.

[0040] (3) Select 4kv pulse high-voltage power supply;

[0041] (4) Three kinds of energy superposition of electric explosion, gas explosion and plasma are used for surface treatment of T10 taps. Adjust the distance between the nozzle of the pulse plasma gun and the tap to 80mm, the tap rotates at a speed of five revolutions per minute, and bombards the surface of the tap with a pulse frequency of 15HZ in the atmospheric environment, and the sample processing time is 20s;

[0042] The treated T10 tap was installed on the machine tool for trial, and its service life was increased by 2-4 times compared with the unstrengthened...

example 3

[0044] (1) Select 45 steel gears as the processing object, and select molybdenum alloy wire with a diameter of Ф4mm as the consumable metal electrode wire;

[0045] (2) Propane is selected as the combustible gas and mixed with oxygen in proportion C3H8:O2=1:5. The process parameters are set as follows: mixed gas pressure 0.75MPa, flow rate 30L / min.

[0046] (3) Choose a voltage of 3kv;

[0047] (4) The surface treatment of 45 steel gears is carried out by superimposing two kinds of energy, gas explosion and plasma. Adjust the distance between the nozzle of the pulse plasma gun and the gear to 60mm, the gear rotates at a speed of ten revolutions per minute, and the high-energy particle jet bombards the surface of the 45 steel gear in the atmospheric environment with a pulse frequency of 10HZ, and the sample processing time is 20s ;

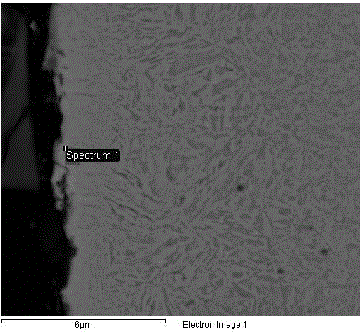

[0048] Using a scanning electron microscope (SEM) to observe the cross-sectional morphology of the treated sample, it can be seen from Figure 5(a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com