Preparation method of lithium ion battery cathode material

A kind of technology of lithium ion battery and negative electrode material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

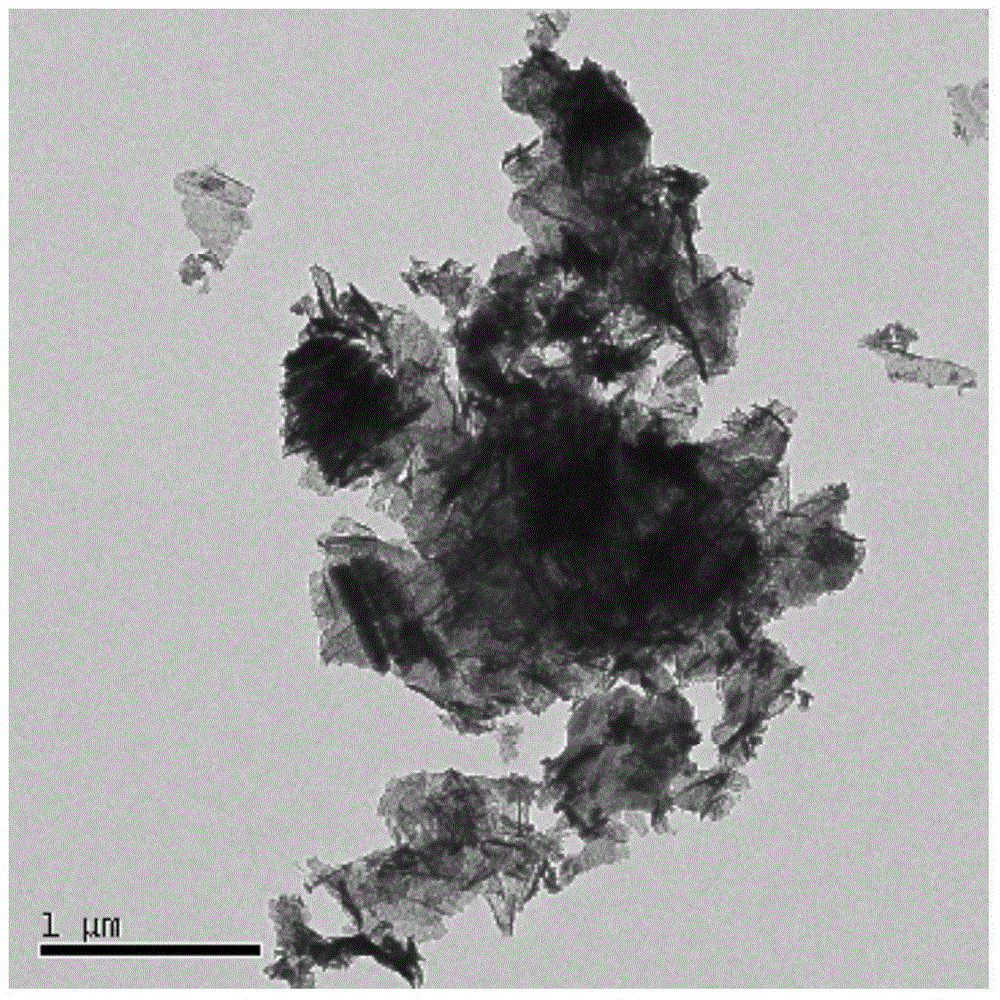

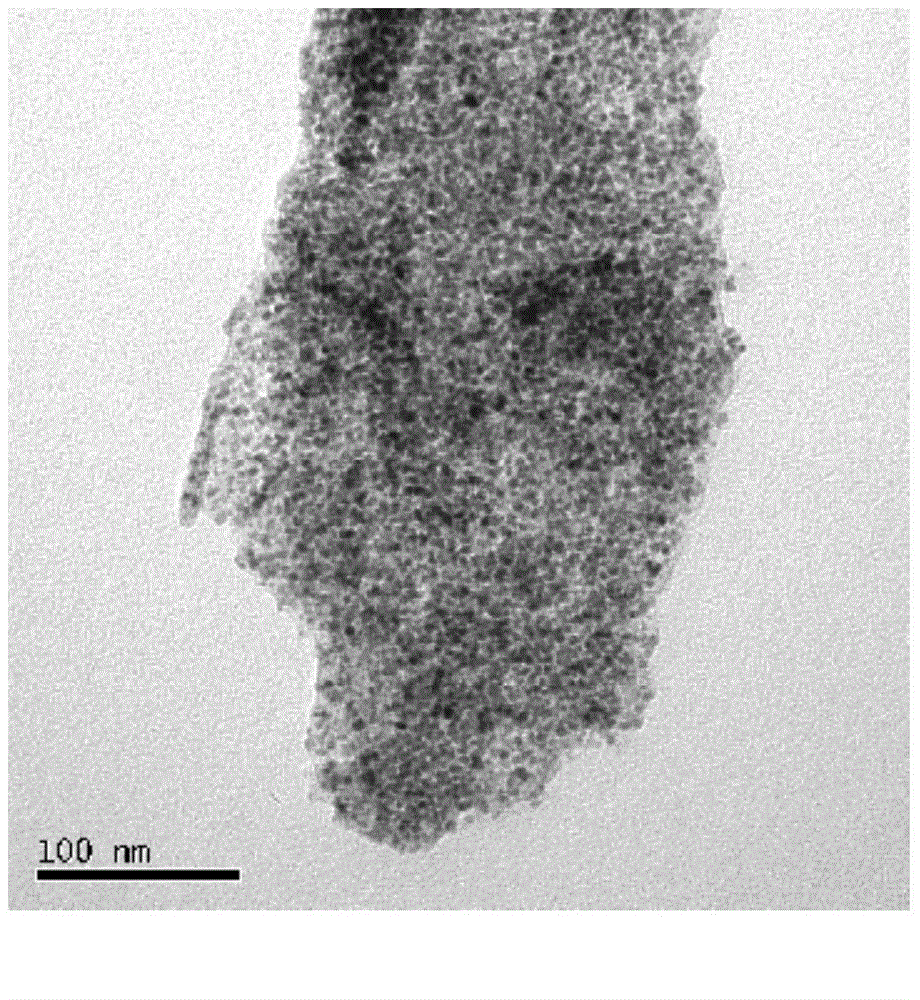

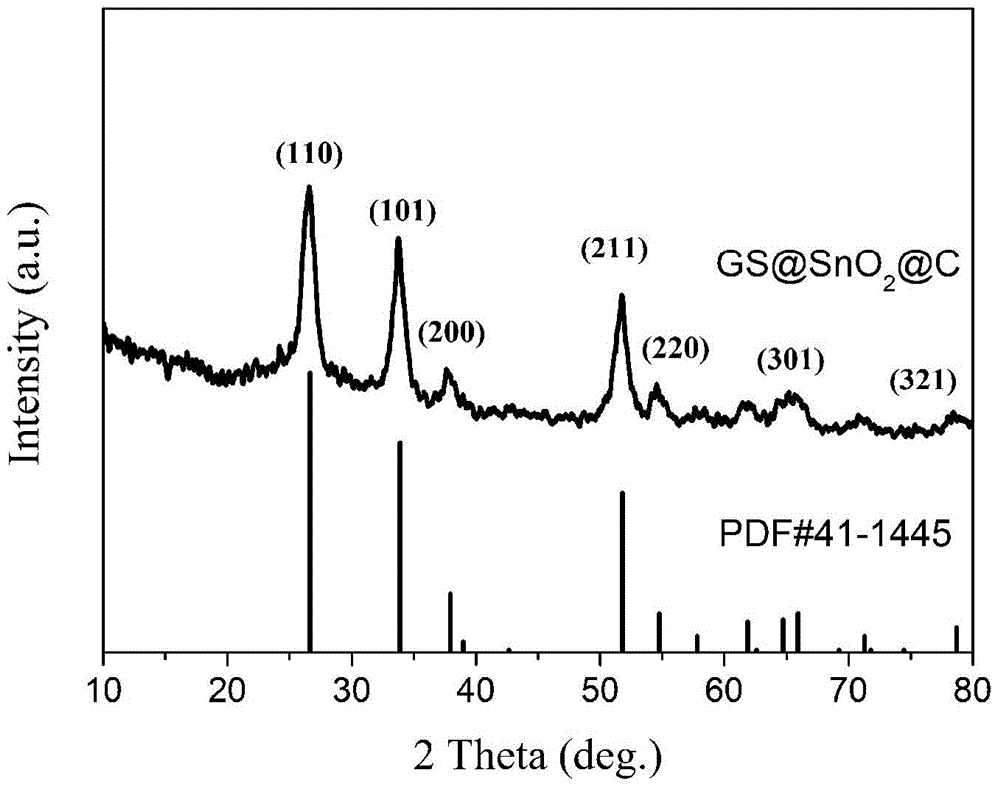

Image

Examples

Embodiment 1

[0040] The preparation method of a kind of negative electrode material of lithium-ion battery provided by this embodiment comprises the following steps:

[0041] The first step is to disperse 40 mg of graphene oxide into 80 mL of deionized water by means of ultrasonic dispersion, then add 0.6 mL of hydrochloric acid with a mass concentration of 36%, and stir and mix evenly to obtain solution A;

[0042] In the second step, 1.2g tin protochloride (with two waters of crystallization, relative molecular weight is 225.65) is added in solution A, and tin protochloride is completely dissolved, obtains solution B;

[0043] In the third step, the solution B is placed in an environment with a temperature of 60°C and reacted for 6 hours with magnetic stirring, and then centrifuged at a speed of 5000r / min to obtain the reaction product, and the reaction product is washed, specifically, with deionized water for 3 time, and then washed 3 times with absolute ethanol to obtain a graphene-tin...

Embodiment 2

[0051] The preparation method of a kind of negative electrode material of lithium-ion battery provided by this embodiment comprises the following steps:

[0052] In the first step, 120 mg of graphene oxide was dispersed into 80 mL of deionized water by means of ultrasonic dispersion, and then 1.0 mL of hydrochloric acid with a mass concentration of 36% was added, and after mixing evenly by magnetic stirring, solution A was obtained;

[0053] In the second step, 3g tin protochloride (with two waters of crystallization, relative molecular weight is 225.65) is added in solution A, and tin protochloride is dissolved completely, obtains solution B;

[0054] In the third step, the solution B is placed in an environment with a temperature of 70°C and reacted for 10 hours while magnetically stirring, and then centrifuged at a speed of 4000r / min to obtain the reaction product, and the reaction product is washed, specifically, washed with deionized water for 2 time, and then washed 3 ti...

Embodiment 3

[0058] The preparation method of a kind of negative electrode material of lithium-ion battery provided by this embodiment comprises the following steps:

[0059] In the first step, 200 mg of graphene oxide was dispersed into 80 mL of deionized water by means of ultrasonic dispersion, and then 2.0 mL of hydrochloric acid with a mass concentration of 36% was added, and the solution A was obtained after mechanical stirring and mixing;

[0060] In the second step, 5g tin protochloride (with two waters of crystallization, relative molecular weight is 225.65) is added in solution A, and tin protochloride is dissolved completely, obtains solution B;

[0061] In the third step, the solution B is placed in an environment with a temperature of 60°C and reacted for 5 hours while being mechanically stirred, and then centrifuged at a speed of 4000r / min to obtain the reaction product, and the reaction product is washed, specifically, washed with deionized water for 2 time, and then washed 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| First discharge specific capacity | aaaaa | aaaaa |

| First discharge specific capacity | aaaaa | aaaaa |

| First discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com