Industrial gardenia yellow pigment purification device and method for extracting gardenia yellow pigment

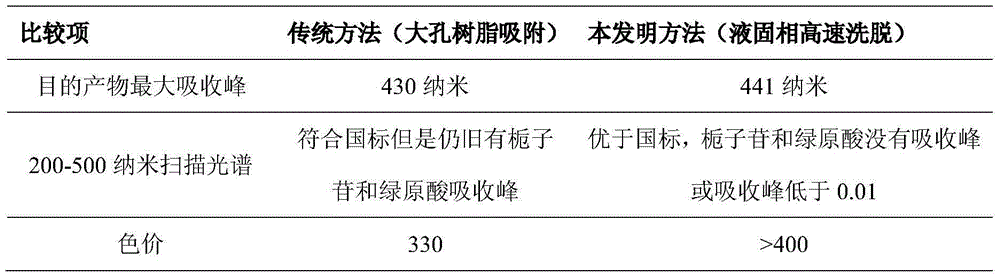

A gardenia yellow pigment and extraction liquid technology, which is applied to chemical instruments and methods, separation methods, evaporator accessories and other directions, can solve the problems of large loss of target products, backward purification technology, prolonged elution cycle, etc., and achieves low cost, The effect of high color price and improved purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

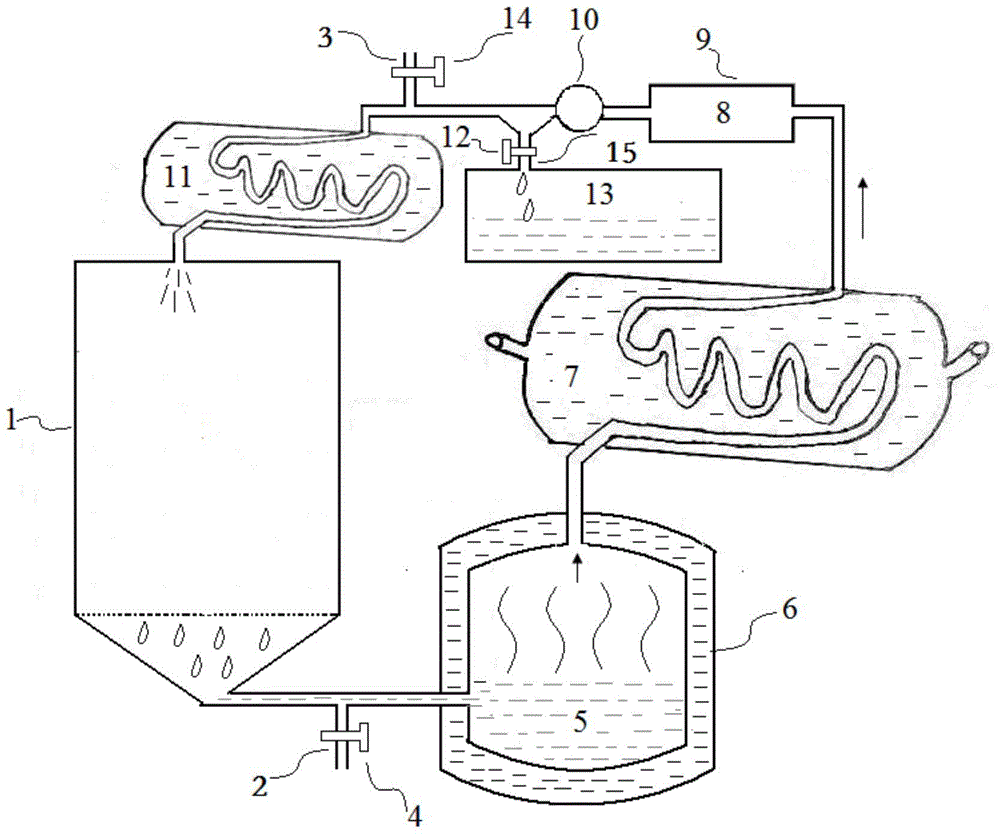

Method used

Image

Examples

Embodiment 1

[0029] A method for purifying gardenia yellow pigment by using the above-mentioned gardenia yellow pigment industrial purification device, comprising the steps of:

[0030] 1) Dry the remaining residue after extracting gardenia oil from gardenia fruits, and then extract it with a food-grade ethanol solution with a concentration of 90%. The extract is concentrated in vacuum at 50°C, dried, and pulverized through a 60-mesh sieve to obtain fine powder.

[0031] 2) Adjust the water temperature of the water bath heater to be 95°C, the condensation temperature of the condenser 7 to be 5°C and the heating temperature of the solvent heater to be 80°C, then close the sampling valve, the collection valve and the inlet valve, and then the obtained in step 1) The fine powder is loaded into the elution column, and the height of the loading is two-thirds of the height of the elution column, and then the elution column is filled with food-grade anhydrous ethyl acetate.

[0032]3) Turn on th...

Embodiment 2

[0037] A method for purifying gardenia yellow pigment by using the above-mentioned gardenia yellow pigment industrial purification device, comprising the steps of:

[0038] 1) Dry the remaining residue after extracting gardenia oil from gardenia fruit, and then extract it with 70% food-grade ethanol. The extract is concentrated in vacuum at 60°C, dried, and crushed through a 100-mesh sieve to obtain a fine powder. powder.

[0039] 2) adjust the water temperature of the water bath heater to be 90°C, the condensation temperature of the condenser 7 to be 15°C and the heating temperature of the solvent heater to be 60°C, then close the sampling valve, the collection valve and the inlet valve, and then the obtained in step 1) Load the fine powder into the elution column, the height of which is half of the height of the elution column, close the valve at the bottom of the elution column, and then fill the elution column with food anhydrous petroleum ether. Water petroleum ether can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com