Cooling device for high-temperature ammonia-containing gas sampling system

A ammonia-containing gas and sampling system technology, applied in the field of power plant chemical industry, can solve the problems of inability to obtain the gas phase at the outlet of the hydrolyzer in the shortest time, the slow cooling rate of the required gas, and the low utilization rate of the cooling medium, etc., to achieve random assembly and coordination , simple structure, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

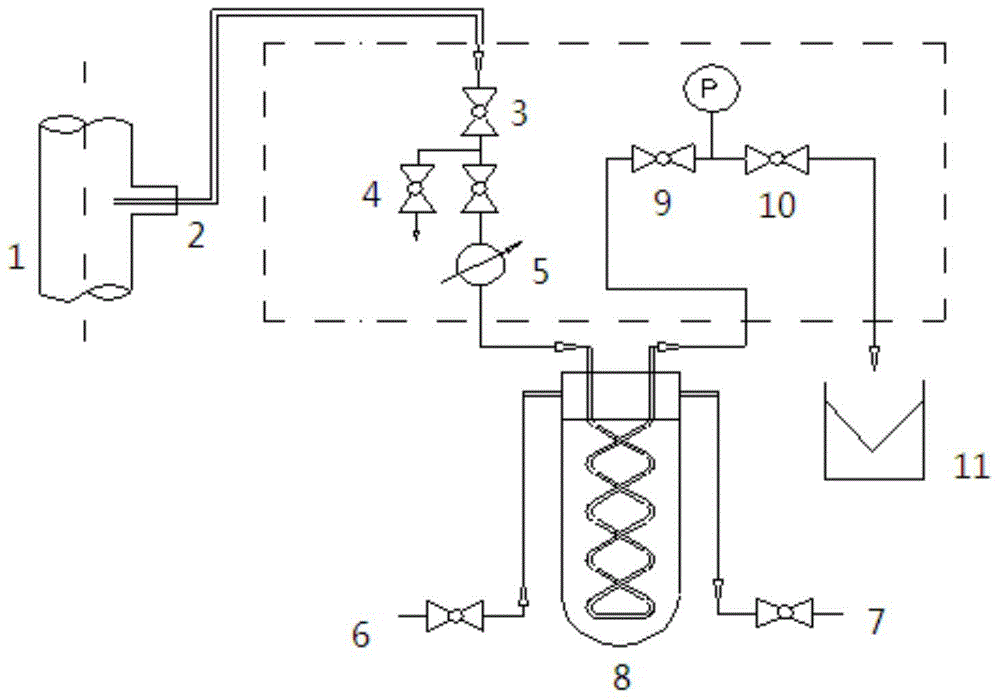

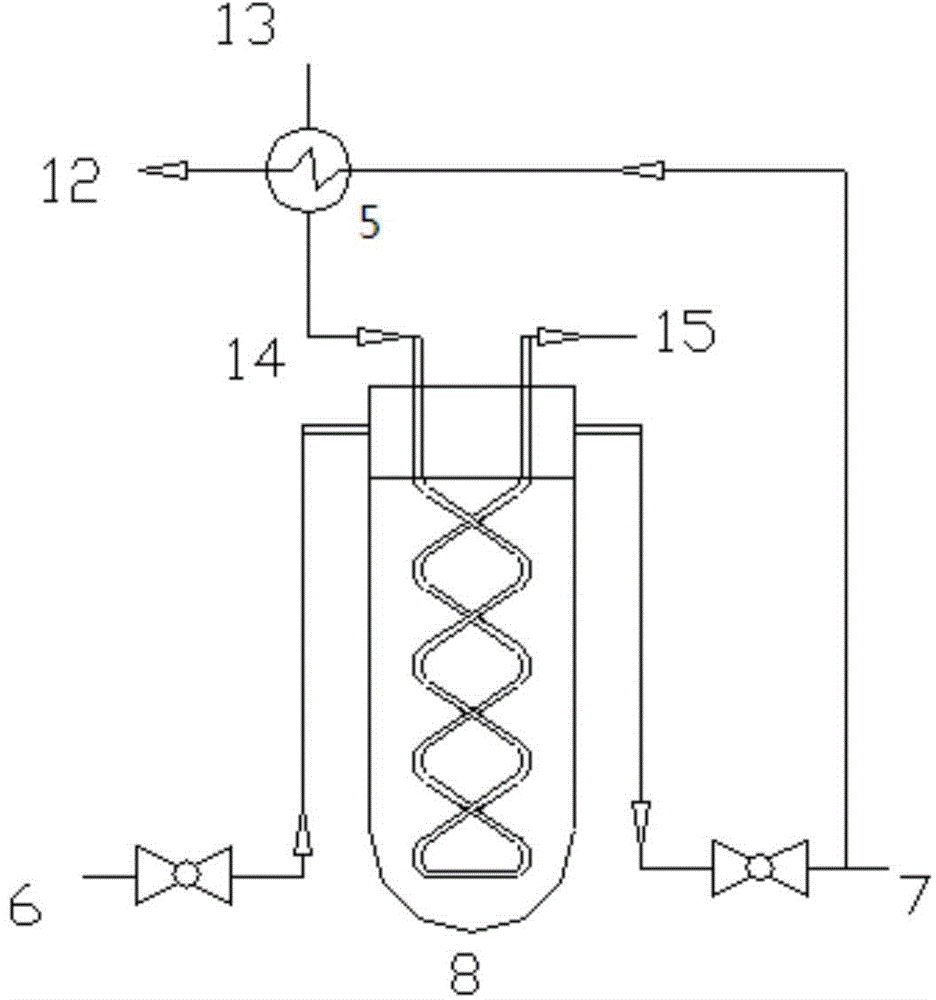

[0033] A cooling device for a high-temperature ammonia-containing gas sampling system of the present invention, such as figure 1 As shown, it includes a sampling pipeline 2 connected to the main pipeline 1 of the gas phase outlet of the reactor, and a precooler 5 and a sampling cooler 8 sequentially connected to the sampling pipeline; the sampling pipeline 2 is sequentially provided with a high temperature and high pressure valve group 3 and A high temperature and high pressure blowdown valve 4; a pressure reducing valve 9, a sampling valve 10 and a sampling container 11 are sequentially arranged on the pipeline connected to the sample gas outlet 15 of the cooler; figure 2 As shown, the sampling cooler group in this preferred embodiment is composed of a sampling cooler 8, which is suitable for the situation where the concentration of ammonia gas in the gas sample is low or the moisture content in the components is relatively small. A sample cooler 8 is provided with a precooler...

example 2

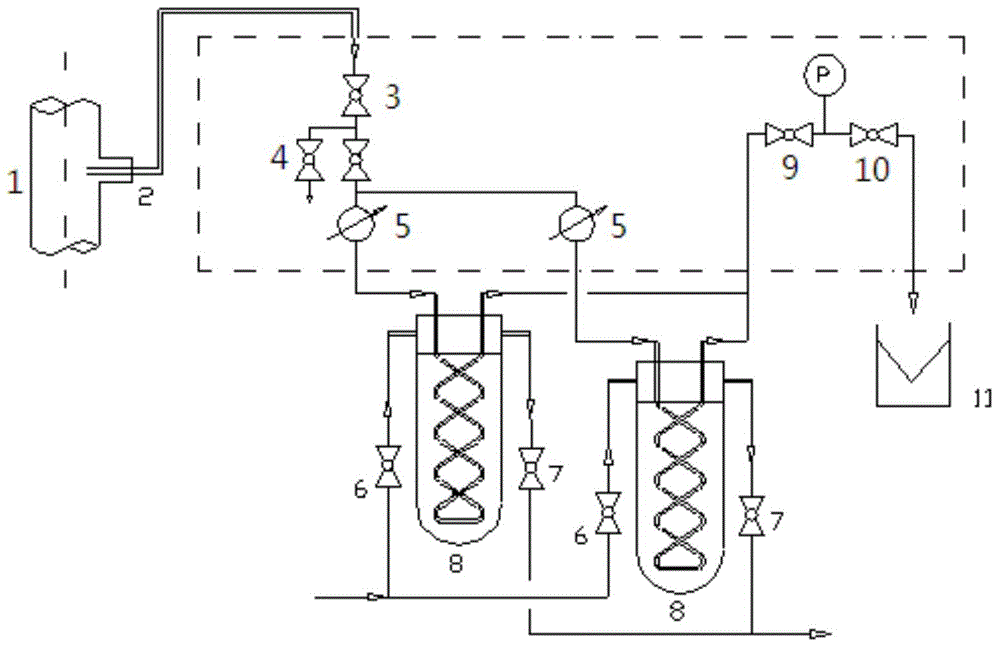

[0035] A cooling device for a high-temperature ammonia-containing gas sampling system of the present invention, such as image 3 As shown, on the basis of Example 1, a group of cooling devices is added in the sampling cooler group connected to the sampling pipeline 2 on the main gas phase pipeline 1 of the reactor outlet, and is arranged behind the high temperature and high pressure sampling valve group, divided into two ways Enter the two pre-coolers 5 respectively, and then enter the respective sampling coolers 8 respectively. The sample gas from the respective sampling coolers 8 enters the pipeline in front of the pressure reducing valve 9 for follow-up sampling work after being processed by heat exchange and cooling. From the outside of the unit, they enter the water inlets 6 of the two sets of sampling coolers 8 through ball valve control respectively. After heat exchange, the cooling medium is discharged from the respective sampling coolers. It is reused, and then discha...

example 3

[0037] A cooling device for a high-temperature ammonia-containing gas sampling system of the present invention, such as Figure 4 As shown, for the case where the concentration of ammonia gas in the gas sample is high or the water content in the components is relatively high, due to the difference in the concentration of the urea aqueous solution, the proportions of ammonia, water, and carbon dioxide contained in the gas phase are also different. If the component content of ammonia and carbon dioxide is not affected at the same time, only neutral desiccants can be used, but most commonly used neutral desiccants cannot be used because they react with product gas to form other products. In order to better test the ammonia content in the product gas, two special filler coolers can be set up to conduct the treatment test twice. The sample gas sampled for the first time only passes through the sampling cooler filled with carbon dioxide solid absorbent 16, Dry moisture and carbon di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com